Versatile, powerful and low maintenance

ScotTruss is the most advanced and comprehensive light gauge steel truss system available and includes a powered decoiler, ScotTruss CNC software and Truswal design and engineering software. It’s easy to operate and adjust offering a low maintenance truss fabrication solution.

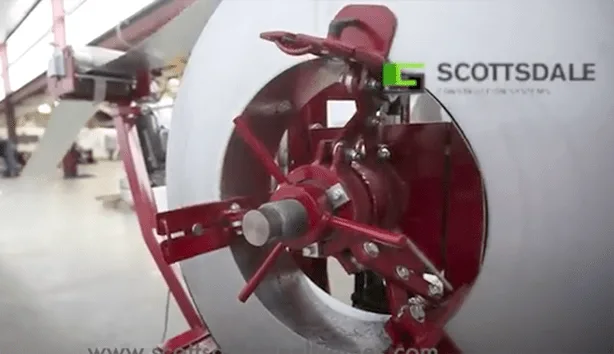

Eliminating scrap, truss components are produced directly from the coil to the assembly line. The computer controlled RF600 rollformer accurately rolls the chord/web profile through nine progressive stations. This is where the full power and efficiency of the equipment comes into play.

Five specific functions are hydraulically performed within the toolhead with elements cut to exact length, coped, notched and bolt holes punched to produce components ready for assembly into a completed truss.

A patented profile is used to form the truss chord and web in addition to the holes for the bolted connection.

The ScotTruss system is ideal for both high volume fabrication facilities and on-site jobs.

WATCH Light Gauge Steel Truss Design, Engineering, Fabrication & Site Erection.

Setting the Industry Standard for Excellence in Steel