KFD Framemaker Roll Forming Machines

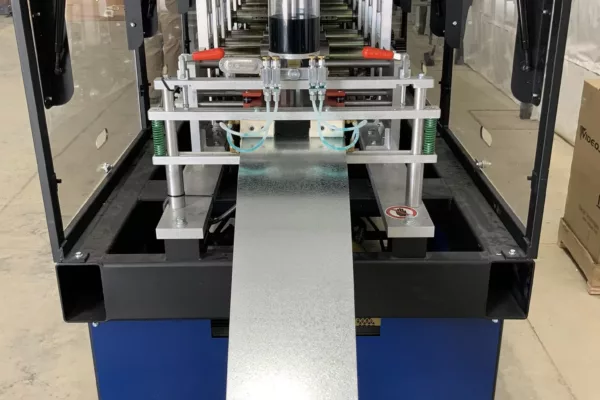

Ideal roll formers for stud and track suppliers, drywall and curtainwall framing, wall and ceiling applications, commercial buildouts, panelized construction, and many other steel framing uses. Knudson by Scottsdale KFD Framemeker roll formers are optimized for non-structural and non-loadbearing uses in interior and exterior framing and include a number of features developed specifically for stud and track suppliers and framing contractors involved in curtainwall applications, such as deflection track slot punches, and much more.

HIGHLIGHTS

Better Performance

Capability of achieving up to 120 feet per minute with a servo (electric) drive with a maximum yield strength of 65 ksi & tensile strength of 75 ksi.

Expert Precision

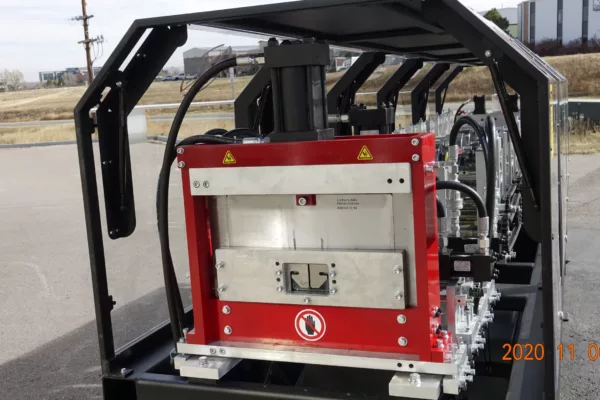

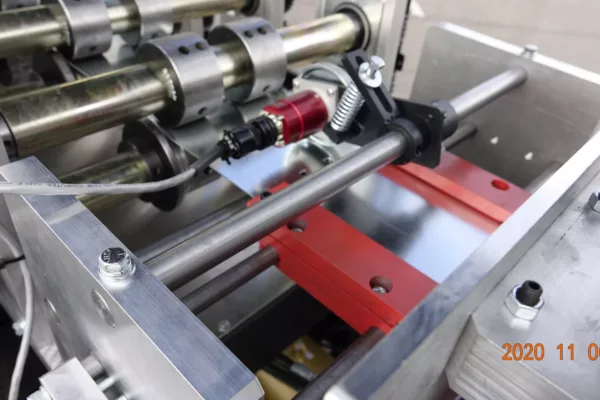

Equipped with hydraulic cut-off and punch tools for precise operations.

Better Efficiency

With an integrated digital batch controller, you get a more efficient process management.

Beyond Standard Customization

Service hole, index, and anchor hole punches for custom, versatile applications.

Compatibility Standards

Meets ASTM A1008 and ASTM 653 standards for Grade 33 structural steel.

Multi-software compatibility

Knudson framing machine controllers are compatible with Strucsoft MWF, ScotSteel, Framebuilder MRD, and Vertex.

KFD FRAMEMAKER MODELS

Features

Brochures & Resources

KFD Framemaker 2025G1

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard power train

- Standard multi-profile shear blade/die kits

- Beck automation SII control kit

- Manual rollformer adjustment

- 4,500-lb (2,040-kg) decoiler

- Web service hole punch toolkit (0.75 x 1.50 in., 19 x 38 mm)

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- Multi-gauge: 25 to 20 Ga (non-structural)

- Multi profile: Web 1.63, 2.50, 3.63, 4.00, 6.00 in.

- Maximum track flange width: 1.5 in. (38 mm)

- Single profile flange: 1.25 in.

- Safety Return

KFD Framemaker 2025G2

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard power train

- Profile-specific sized shear blade/die kits

- AMS control system with ScotRF interoperability

- Manual roll former adjustment

- 6500-lb (2,950-kg) decoiler

- Flange dimpling punch toolkit

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- Web service hole punch toolkit (0.75 x 1.75)

- track slotting toolkit

- Inkjet labeling printer

- Spare parts kit (2-year supply)

- Multi-gauge: 25 to 20 Ga. (non-structural)

- Multi profile: Web 1.63, 2.50, 3.63, 4.00, 6.00 in.

- Maximum track flange width: 2.0 in. (51 mm)

- Single profile flange: 1.25

- Safety Return

KFD Framemaker 2025 Brochures and Resources

Download BrochureGENERAL SPECIFICATIONS

Structural Thickness Range:

- G1: 0.68-1.1 mm (22-18 Ga.)

- G2: 0.68-1.1 mm (22-18 Ga.)

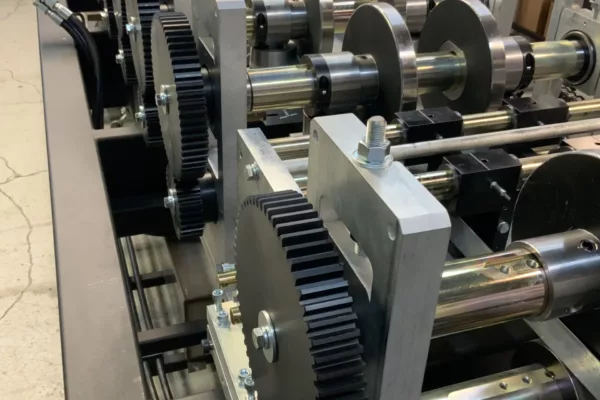

Powertrain:

- G1: Standard 5.5 kW, up to 7,200 ft/hr

- G2: Enhanced 5.5 kW, up to 5,900 ft/hr

Automation and Controls

Rollformer Adjustment:

- G1: Manual

- G2: Automatic

Press State Functionality (Notching & Coping):

- G1: Flat/finished press state functionality

- G2: Flat/finished press state functionality

Decoiler and Warranty

Decoiler:

- G1: 3,300-lb

- G2: 6,500-lb

Maintenance Kit:

- G1: 1-year included

- G2: 2-year included

Warranty:

- G1: 1-year warranty

- G2: 2-year warranty

Licensing and Support

Licensing and Support:

- G1: Complimentary 5,000-m Green Card ScotSteel/ScotRF license credit

- G2: 1-year unlimited ScotRF/ScotSteel license with 24/7 support

Advanced Features

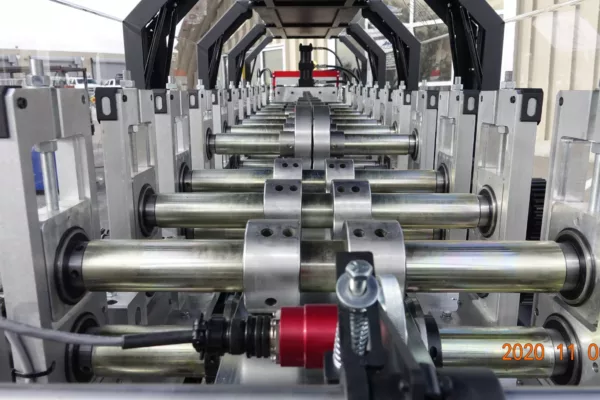

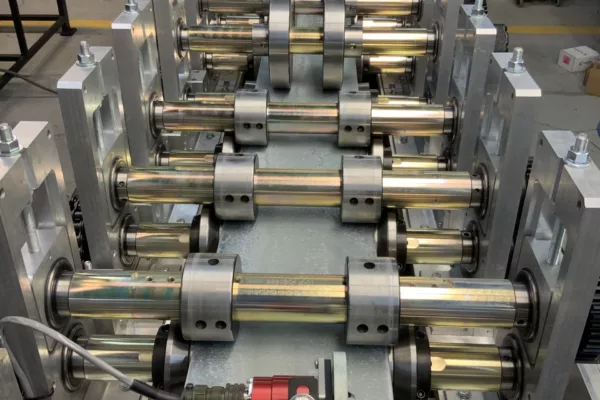

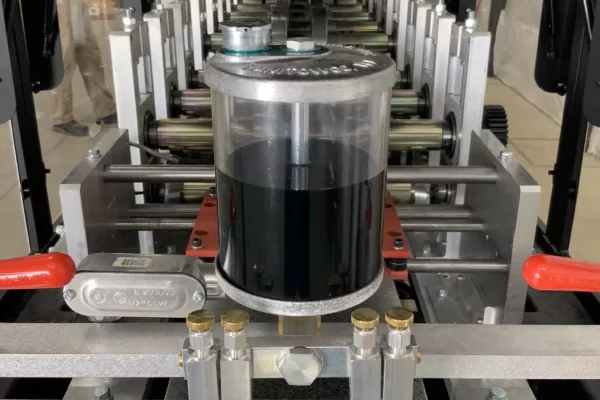

- G1: 9-roller forming cage (lower wear on powertrain), standard workmanship toolkit

- G2: 9-roller forming cage (lower wear on powertrain), enhanced covers with auto-shutoff safety features, printer included