Website: modernstructuralsystems.com | Phone: 706-225-9727

Website: modernstructuralsystems.com

Phone: 706-225-9727

Leading Fabricator of Light Gauge Cold‑Formed Steel

Modern Structural Systems (MSS) is more than a stud supplier — we are a purpose‑built cold‑formed steel (CFS) panelization partner engineered for today’s fast‑paced construction culture.

Inside our 20,000‑square‑foot Augusta, Georgia facility, We have intelligent Scottsdale and Knudson by Scottsdale KFS roll‑formers bending galvanized coil into dimensionally accurate walls, track, floor joists, and roof truss assemblies at up to 120 linear feet per minute. Because we can participate in the entire workflow—from three‑dimensional design through managing logistics that correspond to your schedule — developers, general contractors, and modular builders trust us to hit aggressive schedules without compromising AISI‑S100 structural integrity.

Whether you need high‑volume residential framing packages or a single bespoke mezzanine, our lean manufacturing process flexes to match your project’s size, timeline, and budget. Modern Structural Systems was founded by builders for builders, so every shipment that leaves our dock carries a promise: install faster, straighter, and safer, with fewer labor hours and zero rework. We are there to support you every step of the way.

Our Strategic Location & Delivery Footprint

Centrally located on I‑20 and near the I-95 logistics corridor, Augusta, Georgia gives MSS overnight logistics around the southeast while two‑day flatbed lanes extend north past Boston and west to the Mississippi River. Builders nationwide can rely on just‑in‑time drops or consolidated site staging without storage headaches.

Our shipping team secures and labels each bundle, truss, or panel, so superintendents always know when the next stack is rolling in. We’ll pre‑assemble wall sections for crane picks or lulls. By combining central‑southeast geography with flexible logistics, MSS compresses transportation costs and time, keeping your project moving smoothly.

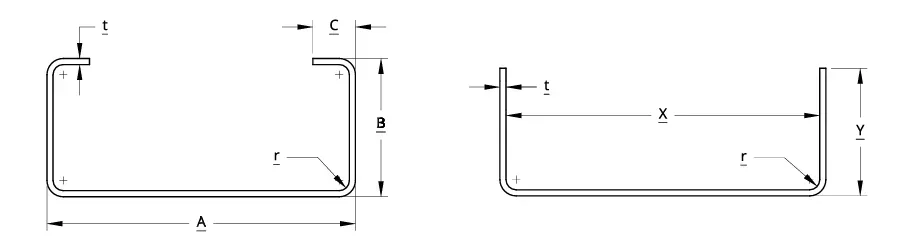

Cold‑Formed Steel Profiles & Sizes

Because no two building envelopes are the same, MSS maintains a deep bench of C‑shapes, truss hats, and tracks certified to SSMA and ASTM benchmarks. All members are roll‑formed from ASTM A1008/A653, 50‑ksi minimum yield steel and tested per AISI‑S100. Our current production catalog, thicknesses are listed in gauge and corresponding mils.

| Width (in) | Profile Type | SSMA / AISI Designation* | Available Gauges |

| 2.00 | Truss Hat | HT200-33, HT200-43 | 20 ga (33 mil), 18 ga (43 mil) |

| 3 ½ | C-Stud | 350S162-33, 350S162-43 | 20 ga (33 mil), 18 ga (43 mil) |

| 3 ⅝ | C-Stud | 362S162-33 → 362S162-97 | 20 → 14 ga (33–97 mil) |

| 4.00 | C-Stud | 400S162-33 → 400S162-97 | 20 → 14 ga |

| 6.00 | C-Stud | 600S162-33 → 600S162-97 | 20 → 14 ga |

| 8.00 | C-Stud | 800S162-33 → 800S162-97 | 20 → 14 ga |

| 10.00 | C-Stud | 1000S162-43 → 1000S162-97 | 18 → 14 ga |

| 12.00 | C-Stud | 1200S200-54 → 1200S200-97 | 16 → 14 ga |

| Width (in) | Flange (in) | Gauge | Thickness (mil) | SSMA Code |

|---|---|---|---|---|

| 3 ⅝ | 1 ⅝ | 20 | 33 | 362S162-33 |

| 3 ⅝ | 1 ⅝ | 18 | 43 | 362S162-43 |

| 3 ⅝ | 1 ⅝ | 16 | 54 | 362S162-54 |

| 3 ⅝ | 1 ⅝ | 14 | 68 | 362S162-68 |

| 3 ⅝ | 2 | 20 | 33 | 362S200-33 |

| 3 ⅝ | 2 | 18 | 43 | 362S200-43 |

| 3 ⅝ | 2 | 16 | 54 | 362S200-54 |

| 3 ⅝ | 2 | 14 | 68 | 362S200-68 |

| 3 ⅝ | 2 ½ | 20 | 33 | 362S250-33 |

| 3 ⅝ | 2 ½ | 18 | 43 | 362S250-43 |

| 3 ⅝ | 2 ½ | 16 | 54 | 362S250-54 |

| 3 ⅝ | 2 ½ | 14 | 68 | 362S250-68 |

| 4 | 1 ⅝ | 20 | 33 | 400S162-33 |

| 4 | 1 ⅝ | 18 | 43 | 400S162-43 |

| 4 | 1 ⅝ | 16 | 54 | 400S162-54 |

| 4 | 1 ⅝ | 14 | 68 | 400S162-68 |

| 4 | 2 | 20 | 33 | 400S200-33 |

| 4 | 2 | 18 | 43 | 400S200-43 |

| 4 | 2 | 16 | 54 | 400S200-54 |

| 4 | 2 | 14 | 68 | 400S200-68 |

| 4 | 2 ½ | 20 | 33 | 400S250-33 |

| 4 | 2 ½ | 18 | 43 | 400S250-43 |

| 4 | 2 ½ | 16 | 54 | 400S250-54 |

| 4 | 2 ½ | 14 | 68 | 400S250-68 |

| 6 | 1 ⅝ | 20 | 33 | 600S162-33 |

| 6 | 1 ⅝ | 18 | 43 | 600S162-43 |

| 6 | 1 ⅝ | 16 | 54 | 600S162-54 |

| 6 | 1 ⅝ | 14 | 68 | 600S162-68 |

| 6 | 2 | 20 | 33 | 600S200-33 |

| 6 | 2 | 18 | 43 | 600S200-43 |

| 6 | 2 | 16 | 54 | 600S200-54 |

| 6 | 2 | 14 | 68 | 600S200-68 |

| 6 | 2 ½ | 20 | 33 | 600S250-33 |

| 6 | 2 ½ | 18 | 43 | 600S250-43 |

| 6 | 2 ½ | 16 | 54 | 600S250-54 |

| 6 | 2 ½ | 14 | 68 | 600S250-68 |

| 8 | 1 ⅝ | 20 | 33 | 800S162-33 |

| 8 | 1 ⅝ | 18 | 43 | 800S162-43 |

| 8 | 1 ⅝ | 16 | 54 | 800S162-54 |

| 8 | 1 ⅝ | 14 | 68 | 800S162-68 |

| 8 | 2 | 20 | 33 | 800S200-33 |

| 8 | 2 | 18 | 43 | 800S200-43 |

| 8 | 2 | 16 | 54 | 800S200-54 |

| 8 | 2 | 14 | 68 | 800S200-68 |

| 8 | 2 ½ | 20 | 33 | 800S250-33 |

| 8 | 2 ½ | 18 | 43 | 800S250-43 |

| 8 | 2 ½ | 16 | 54 | 800S250-54 |

| 8 | 2 ½ | 14 | 68 | 800S250-68 |

| 10 | 1 ⅝ | 20 | 33 | 1000S162-33 |

| 10 | 1 ⅝ | 18 | 43 | 1000S162-43 |

| 10 | 1 ⅝ | 16 | 54 | 1000S162-54 |

| 10 | 1 ⅝ | 14 | 68 | 1000S162-68 |

| 10 | 2 | 20 | 33 | 1000S200-33 |

| 10 | 2 | 18 | 43 | 1000S200-43 |

| 10 | 2 | 16 | 54 | 1000S200-54 |

| 10 | 2 | 14 | 68 | 1000S200-68 |

| 10 | 2 ½ | 20 | 33 | 1000S250-33 |

| 10 | 2 ½ | 18 | 43 | 1000S250-43 |

| 10 | 2 ½ | 16 | 54 | 1000S250-54 |

| 10 | 2 ½ | 14 | 68 | 1000S250-68 |

| 12 | 1 ⅝ | 20 | 33 | 1200S162-33 |

| 12 | 1 ⅝ | 18 | 43 | 1200S162-43 |

| 12 | 1 ⅝ | 16 | 54 | 1200S162-54 |

| 12 | 1 ⅝ | 14 | 68 | 1200S162-68 |

| 12 | 2 | 20 | 33 | 1200S200-33 |

| 12 | 2 | 18 | 43 | 1200S200-43 |

| 12 | 2 | 16 | 54 | 1200S200-54 |

| 12 | 2 | 14 | 68 | 1200S200-68 |

| 12 | 2 ½ | 20 | 33 | 1200S250-33 |

| 12 | 2 ½ | 18 | 43 | 1200S250-43 |

| 12 | 2 ½ | 16 | 54 | 1200S250-54 |

| 12 | 2 ½ | 14 | 68 | 1200S250-68 |

| Web (in) | Gauge | Thickness (mil) | Track code |

|---|---|---|---|

| 3 ⅝ | 20 | 33 | 362T162-33 |

| 3 ⅝ | 18 | 43 | 362T162-43 |

| 3 ⅝ | 16 | 54 | 362T162-54 |

| 3 ⅝ | 14 | 68 | 362T162-68 |

| 4 | 20 | 33 | 400T162-33 |

| 4 | 18 | 43 | 400T162-43 |

| 4 | 16 | 54 | 400T162-54 |

| 4 | 14 | 68 | 400T162-68 |

| 6 | 20 | 33 | 600T162-33 |

| 6 | 18 | 43 | 600T162-43 |

| 6 | 16 | 54 | 600T162-54 |

| 6 | 14 | 68 | 600T162-68 |

| 8 | 20 | 33 | 800T162-33 |

| 8 | 18 | 43 | 800T162-43 |

| 8 | 16 | 54 | 800T162-54 |

| 8 | 14 | 68 | 800T162-68 |

| 10 | 20 | 33 | 1000T162-33 |

| 10 | 18 | 43 | 1000T162-43 |

| 10 | 16 | 54 | 1000T162-54 |

| 10 | 14 | 68 | 1000T162-68 |

| 12 | 20 | 33 | 1200T162-33 |

| 12 | 18 | 43 | 1200T162-43 |

| 12 | 16 | 54 | 1200T162-54 |

| 12 | 14 | 68 | 1200T162-68 |

| 3 ⅝ | 20 | 33 | 362T200-33 |

| 3 ⅝ | 18 | 43 | 362T200-43 |

| 3 ⅝ | 16 | 54 | 362T200-54 |

| 3 ⅝ | 14 | 68 | 362T200-68 |

| 4 | 20 | 33 | 400T200-33 |

| 4 | 18 | 43 | 400T200-43 |

| 4 | 16 | 54 | 400T200-54 |

| 4 | 14 | 68 | 400T200-68 |

| 6 | 20 | 33 | 600T200-33 |

| 6 | 18 | 43 | 600T200-43 |

| 6 | 16 | 54 | 600T200-54 |

| 6 | 14 | 68 | 600T200-68 |

| 8 | 20 | 33 | 800T200-33 |

| 8 | 18 | 43 | 800T200-43 |

| 8 | 16 | 54 | 800T200-54 |

| 8 | 14 | 68 | 800T200-68 |

| 10 | 20 | 33 | 1000T200-33 |

| 10 | 18 | 43 | 1000T200-43 |

| 10 | 16 | 54 | 1000T200-54 |

| 10 | 14 | 68 | 1000T200-68 |

| 12 | 20 | 33 | 1200T200-33 |

| 12 | 18 | 43 | 1200T200-43 |

| 12 | 16 | 54 | 1200T200-54 |

| 12 | 14 | 68 | 1200T200-68 |

| 3 ⅝ | 20 | 33 | 362T250-33 |

| 3 ⅝ | 18 | 43 | 362T250-43 |

| 3 ⅝ | 16 | 54 | 362T250-54 |

| 3 ⅝ | 14 | 68 | 362T250-68 |

| 4 | 20 | 33 | 400T250-33 |

| 4 | 18 | 43 | 400T250-43 |

| 4 | 16 | 54 | 400T250-54 |

| 4 | 14 | 68 | 400T250-68 |

| 6 | 20 | 33 | 600T250-33 |

| 6 | 18 | 43 | 600T250-43 |

| 6 | 16 | 54 | 600T250-54 |

| 6 | 14 | 68 | 600T250-68 |

| 8 | 20 | 33 | 800T250-33 |

| 8 | 18 | 43 | 800T250-43 |

| 8 | 16 | 54 | 800T250-54 |

| 8 | 14 | 68 | 800T250-68 |

| 10 | 20 | 33 | 1000T250-33 |

| 10 | 18 | 43 | 1000T250-43 |

| 10 | 16 | 54 | 1000T250-54 |

| 10 | 14 | 68 | 1000T250-68 |

| 12 | 20 | 33 | 1200T250-33 |

| 12 | 18 | 43 | 1200T250-43 |

| 12 | 16 | 54 | 1200T250-54 |

| 12 | 14 | 68 | 1200T250-68 |

Markets & Applications We Power

From single‑family infill, multifamily structures, to large warehouses, our framing kits keep schedules honest and crews moving.

- Residential builders lean on our laser‑straight studs to eliminate drywall call‑backs, while commercial contractors appreciate the weight savings and environmental resilience on mid‑rise hotels and schools.

- In the industrial sector, MSS fabricates code‑compliant mezzanines or specialty conveyers structures that integrate with pre‑engineered components.

- Specialty teams call us for unique builds—think decorative grottos for resort pools, acoustically isolated office pods, and municipal dumpster enclosures that actually look good.

Because our engineers stamp in all 50 states, one vendor can follow your brand rollout from Florida to California without re‑vetting suppliers or juggling regional fabricators.

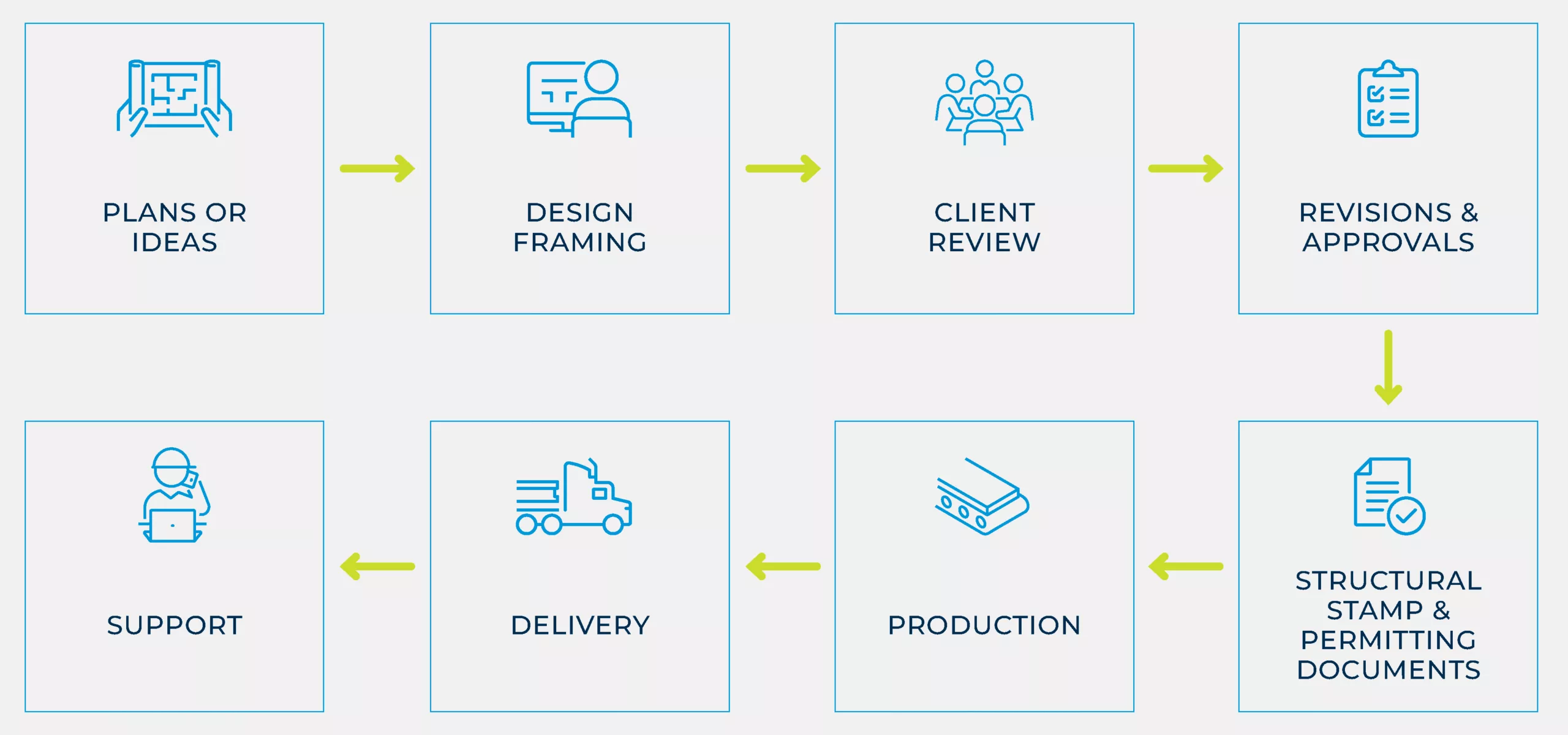

Turn‑Key Professional Services

Great framing starts long before coil runs though the rollers.

MSS wraps architecture, BIM detailing, structural engineering, construction services, and logistics into a single accountable contract.

- Our technicians deliver clash‑free models complete with CNC punch and service hole data, eliminating RFIs downstream.

- PE‑sealed calculations arrive alongside the model, so permit reviewers see exactly the same geometry the field will receive.

- When production begins, our automated nesting software reduces waste and chop stations and labeling makes on‑site sequencing intuitive even for first‑time CFS crews.

- Need installation labor? We can dispatch MSS-affiliated field supervisors or partner with your preferred GC to erect panels, set trusses, and attach decking.

- Finally, our logistics coordinators secure back‑haul rates to make your job easier if needed.

Partners Across the Construction Supply Chain

Whether you’re sketching a napkin idea or pouring though large sets of government plans, MSS meets you where you work.

- Architects value our early‑phase design assist that optimizes spans without boxing in aesthetics.

- Structural engineers trust our in‑house PE team to share rational analysis models and respect governing codes.

- General contractors lean on our experience to keep site schedules tight.

- Trade specialists appreciate knock‑outs pre‑punched for MEP rough‑ins, slashing drill‑and‑burn labor.

- Developers and owners see faster rent commencement and lower builders risk insurance or life‑cycle costs thanks to non‑combustible materials and superior thermal performance.

- Even material distributors and modular factories partner with MSS to fill surge capacity or supply niche profiles.

In short, every node of the construction value chain taps us for something different, yet all walk away with the same benefit: predictable performance, transparent communication, and steel that fits into place like it belongs—because it does.