Steel’s exceptional strength, durability, and favorable strength-to-weight ratio have made it a cornerstone of modern construction. Among the most transformative developments is light gauge steel frame construction, a method that’s reshaping how architects, engineers, and builders approach both residential and commercial projects.

In this blog, we’ll explore the latest innovations in light gauge steel frame building construction and how these systems are driving the future of the built environment.

What Is Light Gauge Steel Framing?

Light gauge steel framing, often referred to as cold-formed steel framing, uses steel coils typically less than ¼ inch thick to create precise, lightweight structural components like studs, joists, and trusses.

While the terms “light gauge” and “cold-formed” are sometimes used interchangeably, light gauge specifically refers to the thinness of the steel used, making it distinct from heavier, hot-rolled structural steel. These components are mechanically fastened to form a strong, rigid framework that serves as the skeleton for a building.

Unlike traditional wood framing, light gauge steel frame construction offers greater dimensional stability, resistance to warping, and improved longevity.

As a result, it’s increasingly favored in a wide range of applications, from custom homes and multifamily units to large-scale commercial and industrial buildings.

What Is Cold-Formed Steel?

Cold-formed steel (CFS) refers to structural components made by shaping thin sheets of high-quality steel through a series of roll-forming dies, without the use of heat.

This process allows the steel to be formed into precise shapes such as C-sections, tracks, and channels. The “cold-formed” designation distinguishes it from hot-rolled steel, which is shaped at high temperatures.

CFS is available in a range of thicknesses, making it suitable for both structural and non-structural applications in light gauge steel frame construction. Its strength, precision, and corrosion resistance make it a preferred material for framing walls, floors, and roofs in modern building systems.

Modern Steel Framing with Light Gauge Steel

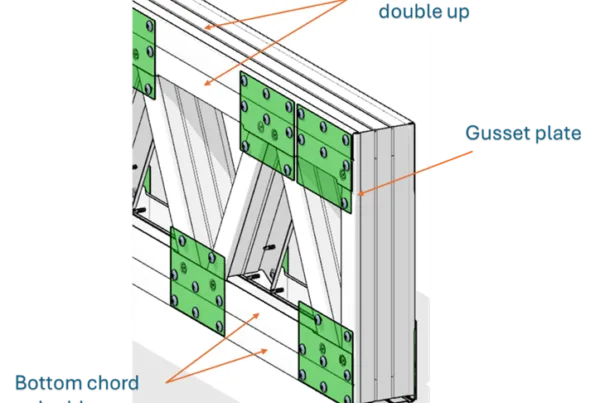

Modern steel framing is a building technique that utilizes light gauge steel frame construction methods to create the structural skeleton of a building. This approach relies on cold-formed steel (CFS) components, such as wall studs, floor joists, ceiling panels, and roof trusses—that are formed from thin steel sheets and assembled using mechanical fasteners like screws or rivets.

As opposed to wood framing, which can warp, rot, or shift over time, light gauge steel offers exceptional dimensional stability and durability.

These lightweight yet high-strength steel frames provide the lateral stability and load-bearing capacity necessary for a wide range of projects, from single-family homes to large-scale commercial buildings.

By leveraging cold-formed steel, builders can achieve more consistent quality, tighter tolerances, and longer-lasting performance, making light gauge steel frame building construction an increasingly preferred method across the industry.

The Rise of Prefabricated Steel Components

One of the most transformative trends in light gauge steel frame construction is the shift toward prefabricated components. Thanks to advances in computer-aided manufacturing and automated roll-forming machines, steel framing systems can now be fabricated with pinpoint accuracy off-site and then quickly assembled on location.

Prefabrication not only shortens project timelines but also reduces on-site labor demands and construction waste. In a controlled environment, manufacturers can optimize quality control, minimize errors, and deliver framing systems that arrive ready to install.

This shift is especially beneficial for developers seeking speed, consistency, and cost-efficiency, core advantages that are driving the adoption of light gauge steel frame building construction in both residential and commercial markets.

According to the Steel Framing Industry Association (SFIA), prefabricated steel framing can reduce framing time by up to 50% compared to traditional methods.

Sustainable Steel Structures with Light Gauge Framing

Sustainability is one of the most compelling advantages of light gauge steel frame construction. Unlike wood or concrete, steel is 100% recyclable without any degradation in strength, meaning the same material can be reused in multiple building lifecycles.

In fact, according to the Steel Recycling Institute, steel is the most recycled material in the world, with more than 80 million tons recycled annually in the U.S. alone.

Because light gauge steel components are prefabricated with precision, there is significantly less on-site waste during the construction process. The lightweight nature of the material also lowers transportation emissions and energy consumption during delivery.

Modern light gauge steel frame building construction supports green building practices by:

- Utilizing recycled steel content

- Reducing construction waste

- Supporting energy-efficient building envelopes

- Enabling passive design strategies due to precision framing

As architects and developers adopt more environmentally conscious design principles, steel framing continues to gain traction as a sustainable solution for both residential and commercial construction.

How Scottsdale Steel Frames Advances Sustainable Light Gauge Steel Frame Construction

Companies like Scottsdale Construction Systems exemplify its eco-friendly use in real-world projects. Here’s how:

- 100% Recyclable Materials: Scottsdale underscores that steel is 100% recyclable, helping reduce carbon emissions and landfill impact

- High Material Utilization, Minimal Waste: our off-site precision manufacturing delivers over 99% material utilization, dramatically cutting scrap and rework during construction.

- Prefabrication for Reduced Footprint: By fabricating steel components in controlled environments, Scottsdale reduces on-site waste and energy use in our steel framing systems. Transporting prefabricated light gauge steel frame construction units further lowers emissions

- Supports Green Building Certifications: Our cold-formed steel systems contribute toward LEED, ICC-700, ASHRAE 189.1, and IgCC environmental credits through recycled content and efficient framing practices

- Lifecycle Durability: Steel-framed buildings by Scottsdale offer long service lives with minimal upkeep, ensuring lower maintenance and lifecycle environmental costs

By combining precision manufacturing with eco-conscious design, Scottsdale empowers builders to adopt more sustainable practices without compromising on strength or efficiency.

As demand grows for environmentally responsible construction methods, light gauge steel frame construction stands out as a scalable solution for reducing waste, lowering emissions, and building for the future.

Architectural Flexibility in Light Gauge Steel Frame Construction

One of the most exciting developments in light gauge steel frame construction is the integration of advanced structural systems that improve strength, efficiency, and design potential.

Innovations like moment-resisting frames and composite steel structures enhance a building’s ability to withstand lateral forces such as wind and seismic activity, making them ideal for a wide range of climates and code requirements.

Additionally, systems like lattice steel trusses allow for long spans without the need for intermediate support columns. This capability supports wide-open interior layouts and flexible space planning, hallmarks of modern commercial and residential architecture.

Innovative Design Possibilities with Light Gauge Steel Frame Building Construction

Architects are increasingly turning to light gauge steel frame building construction for the freedom it provides in design execution. Unlike traditional materials, light gauge steel can be used to craft curved facades, dynamic rooflines, and expansive glazing systems that flood interiors with natural light. Its structural reliability allows for tall, slender profiles without compromising stability, unlocking new potential in both form and function.

This versatility not only enhances visual appeal but also supports sustainable, people-centered design by creating well-lit, energy-efficient spaces that connect more naturally with the surrounding environment. Learn more about our steel framing projects here.

Embracing Digital Innovation in Light Gauge Steel Frame Construction

As the construction industry continues its digital transformation, light gauge steel frame construction is at the forefront of innovation. Design software enhances collaboration, minimizes errors, and ensures accurate cost estimation.

Digital modeling allows teams to visualize and optimize every aspect of a steel frame structure before materials are ever cut or shipped. This level of precision not only minimizes waste and rework but also speeds up on-site installation.

When paired with prefabrication, these technologies streamline the entire project lifecycle, from initial concept to final build.

For forward-thinking builders, embracing digital steel frame technologies is no longer optional, it’s essential for delivering smarter, faster, and more cost-effective structures.

The Advantages of Composite Steel Beams in High-Rise Construction

Light gauge steel frame building construction has expanded beyond low-rise residential and commercial applications, thanks in part to innovations like cold-formed steel composite beams. These hybrid systems combine the strength of steel with the performance benefits of materials like reinforced concrete, creating a high-efficiency structural element ideal for high-rise construction.

By embedding concrete into or atop light gauge steel joists and beams, engineers significantly boost load-carrying capacity and thermal performance, while also improving fire resistance and reducing the overall weight of the structure.

The result is a stronger, lighter building frame that accelerates construction timelines and unlocks new vertical design potential.

Composite steel beam systems are now widely adopted in high-rise developments due to:

- Superior strength-to-weight ratios

- Enhanced fire resistance

- Faster floor assembly

- Greater flexibility in architectural design

These advancements have made it possible to construct taller, more complex buildings without compromising structural integrity or visual ambition, pushing the limits of what light gauge steel frame construction can achieve in urban environments.

The Importance of Sustainable Practices in Steel Manufacturing

Steel manufacturing plays a vital role in the construction industry, providing the backbone for residential buildings, commercial complex, skyscrapers, bridges, and other large-scale projects.

However, traditional steel production methods have often been associated with high carbon emissions and energy consumption. Embracing sustainable practices is crucial to reduce the environmental impact of this industry.

One promising green material in structural steel manufacturing is recycled steel. By utilizing scrap steel from demolished buildings and end-of-life products, manufacturers can significantly reduce the demand for raw materials and minimize waste sent to landfills. Steel is 100% recyclable and contributes to a more sustainable construction process.

Green coatings, such as water-based paints and powder coatings, offer a sustainable alternative to traditional steel coatings. These coatings are free from harmful substances like volatile organic compounds (VOCs) and heavy metals, reducing the environmental impact and improving the safety of steel structures.

The Future of Modern Construction with Light Gauge Steel Frame Building Systems

The innovative applications of light gauge steel frame construction are redefining what’s possible in modern architecture. From precision-prefabricated components to digitally optimized design and composite structural systems, this method offers unmatched advantages in strength, sustainability, and speed, offering many advantages when building with steel.

As more builders and architects embrace light gauge steel frame building construction, they gain access to an adaptable framework that supports bold design, efficient workflows, and eco-conscious practices.

Whether it’s mid-rise residential buildings, commercial complexes, or high-rise towers, the versatility of light gauge steel is helping the construction industry meet the demands of the future, without sacrificing performance or creativity.

By investing in these forward-thinking technologies and materials, companies like Scottsdale are not only shaping buildings, they’re shaping what comes next in modern construction.

About Scottsdale Construction Systems

Scottsdale Construction Systems is focused on research and development and the innovative development of light gauge steel technology for the residential and commercial construction industries.

Scottsdale Construction Systems has been providing world leading solutions for the manufacture of steel frames and trusses for both the residential and commercial construction markets since its inception in 1995. Contact us today to learn how steel can revolutionize your construction!