High-Performance Rollforming Equipment, Services, and Steel Framing Software

Total LGS Framing Equipment & Technology Package

Ideal sole-source business solution for anyone wishing to set up a steel framing factory or become a metal stud and track supplier.

Scottsdale Construction Systems is a provider of roll forming equipment and complete steel framing technology solutions for businesses wishing to set up or upgrade their manufacturing for the production of metal studs and tracks, LGS steel framing panelized assemblies, or complete structure. We develop and furnish technologically advanced rollforming machinery and design/engineering/CNC software enabling the next-generation construction automation. Scottsdale equipment is ideal for both on-site and off-site construction using prefabricated steel framing.

Our slogan entails two key terms - trust and partnership.

You can completely trust the technology and equipment developed over 70 years of pioneering experience and engineering excellence. All of our roll forming machinery is not only thoroughly for a variety of operating conditions, but it is also perfected through extensive Solidworks modelling by the top industry experts. Every component of our system is not only technologically advanced, but designed to endure and perform. We are also your partners. We only succeed if your business succeeds, whether you are a metal stud and track supplier, an LGS/CFS framing factory, a producer of standing seam roof panels, or a contractor. We assure that through our punctual support. We also provide industry leading experts that can help with factory setup, procurement, design, or general industry knowledge.

Our equipment consist of two brands for broader capabilities

Steel framing and roll forming equipment: Scottsdale and Knudson by Scottsdale Products

Scottsdale branded equipment consists of two families of technologically advanced single-profile steel framing machines: Scotpanel and Scottruss. Our Knudson by Scottsdale machinery consists of two multi-profile machine families: KFS Framemaker (structural roll formers) and KFD Framemaker (nonstructural roll formers). Additionally, Knudson by Scottsdale offers a specialty equipment family of products KSE (seamers, standing seam roll formers, frame extenders, resilient and furring channel roll-forming equipment, and more).

One-stop shop

Whether you are in the market for a multi-profile roll formers or a single-profile high-tech software enabled steel framing machines, or you are a roofing contractor desiring to produce own standing seam panels, or all of the above, we are a one-stop shop for all your needs. The applications span of our over 50 roll-forming machine models cover the application gamut from modular construction to mid-rise apartment application and everything in between, including single-family homes, duplexes, commercial LGS/CFS framing, curtainwall/ceiling framing applications, and much more.

Robust Knowledge Database

Not only do you have access to industry-leading support and world-class experts on rollforming, software, design, and any topics related to fabrication of steel framing, you also have access to our extensive Knowledge Database, which contains answers on virtually any topic germane to LGS framing, cold-formed steel, rollforming, codes and standards, framing details, and much more.

Powerful, high-tech, yet compact and affordable

Whether you favor our Knudson by Scottsdale multi-profile machines or Scottsdale single-profile systems, our objective is to lower the barrier of entry into steel framing by any contractor, framer, panelizer, or supplier desiring to produce their own cold-formed steel members and framing. We even structured our financing programs with that in mind. Our steel framing machines can be deployed in large or small stationary factories or in fully mobile containerized production facilities. We will equip you, fully train you, and our technology will assure that you operate error-free and disruption free immediately.

Breadth of capability

Our stud/frame machinery spans the capability range from Ga. 25 to Ga. 12 and produces at the speed of up to 7,200 ft/min. Our panel machines cold-form the metal over the range of Ga. 29 to Ga. 22. All of our machinery is produced in-house. You are always welcome to our factory during any time of the production process. We sell what we produce. We do not merely label equipment produced by third parties as ours.

Expertise

We have industry unmatched echelon of machinery experts, structural engineers, factory set-up experts, software developers, and business consultants with the skillset perfected over 70 years off cold-formed steel rollforming equipment design and production, and the ensuing over 16,000 machines shipped to over 4,600 customers in over 100 countries.

Support

The 24/7 support in English, Spanish, Portugese, and 8 other languages spanning equipment support, software support, and general cold-formed steel expertise is our key to success. We believe your steel framing factory is schedule-driven and must run at all times.

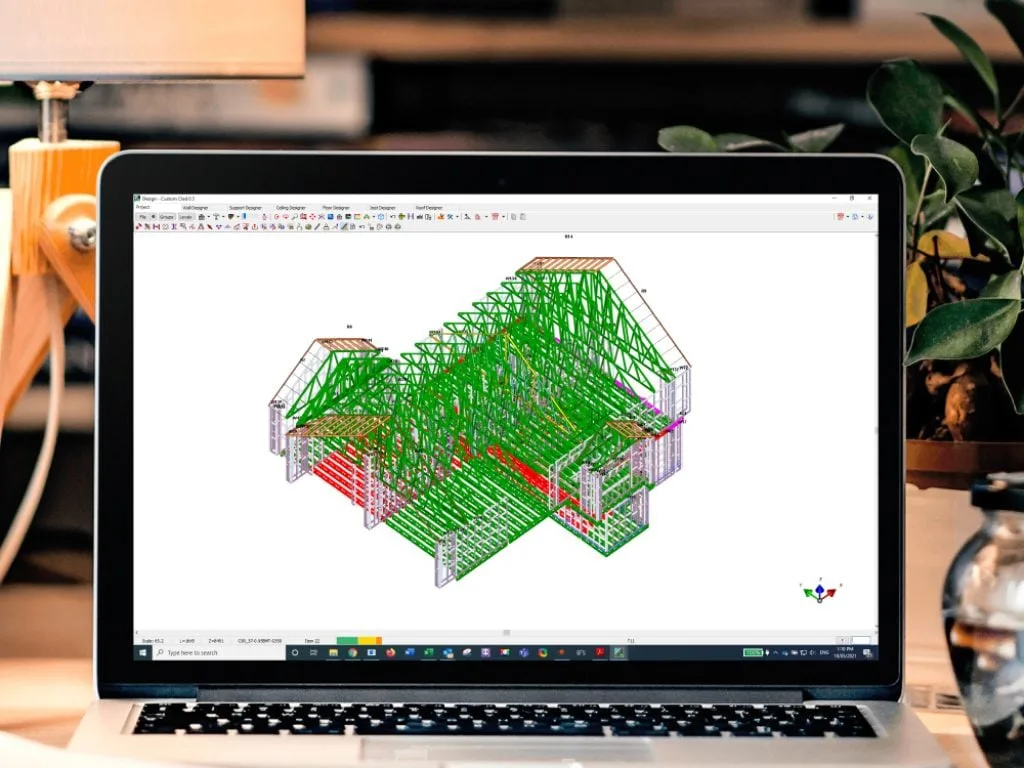

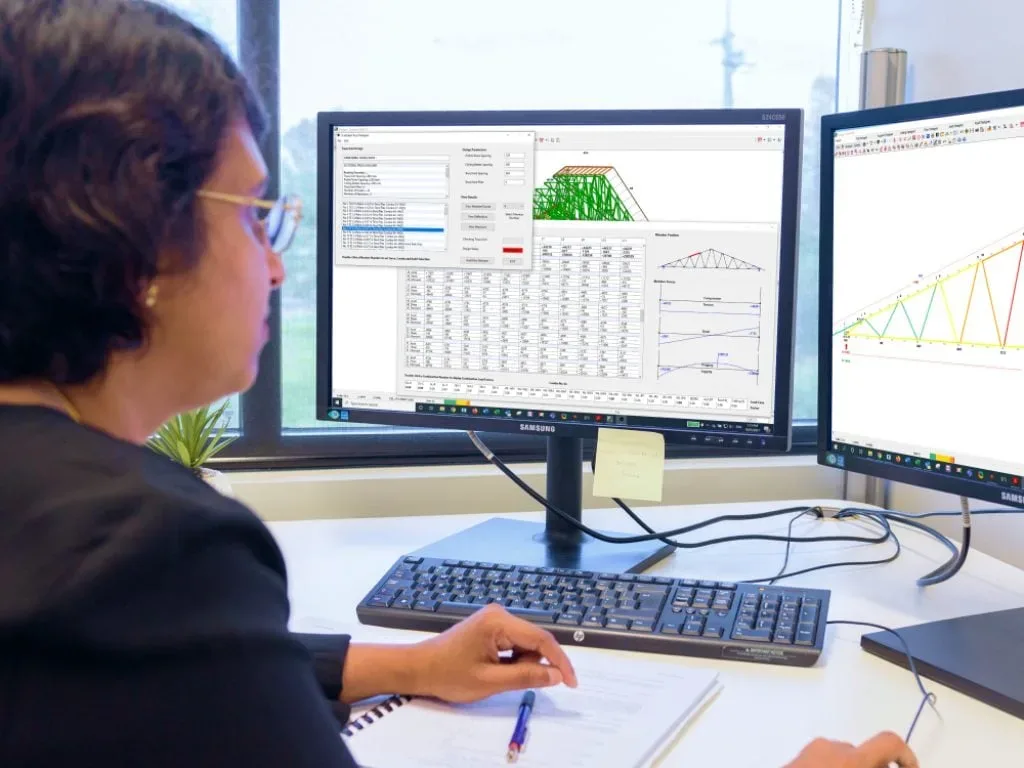

In-house software and extensive third-party software integrations

Our ScotSteel (design/engineering) and ScotRF (CNC production) softwares lead the industry in capability and easy of use. Perfected with fully staffed in-house team of software experts and engineers, this comprehensive solution for the design and engineering is rich with features and modules including production planning tools such as ScotLayout, frame-making simulator ScotSim, or ScotSeismic, our seismic force calculator. Engineering capabilities entail compliance with the latest standards including AS4600, ASCE 7, IBC, AISI S100, and more. Our advanced structural engineering software ScotStruct offers a complete building design solution, including seismic design and global analysis of the lateral force resisting system. We also offer powerful integrations with third-party softwares such as Revit, Strucsoft MWF, Vertex BD, and others. All this enables a seamless design to manufactured frame path unparalleled in the industry. However, don’t take our word for it. Call us today at 1 (888) 406-2080 or e-mail at sales@scottsdalesteelframes.com, ask us for a free demo, and see for yourself!

Complete eco-system for stud and track suppliers, framing businesses, and contractors

Machinery, software, and support are our pillars, but that is not all. We also offer financial products such as equipment financing and insurance, so you can obtain your equipment early and manage your company finances without much stress. Whether you are a builder or an owner, you will benefit from the insurance discounts of using LGS framing produced by Scottsdale equipment, including discounts on builder risk and homeowner insurance. We will also gladly supply you with your input materials should you ask us to do so, including high-quality coil compliant with the applicable global standards such as ASTM A653, AS1397, or EN 10346. If you are in need for design services, fully trained design firms thoroughly trained in ScotSteel software are ready to assist you with licensed professional engineers. We want to make your transition into cold-formed steel training easy and hassle-free and want to provide everything you need to start up or upgrade your manufacturing facility. We will even provide you with CAPEX modelling tools customized to our equipment so you can confidently calculate your profit and ROI on our equipment.

Review some of the additional productivity benefits of our steel framing automation platform in this brief video.

learn more about our solutions

Setting the Industry Standard for Excellence in Steel