Aspire Mickleham Childcare Center – Steel Framed Institutional Building

Steel Framed Childcare Center – Institutional Building

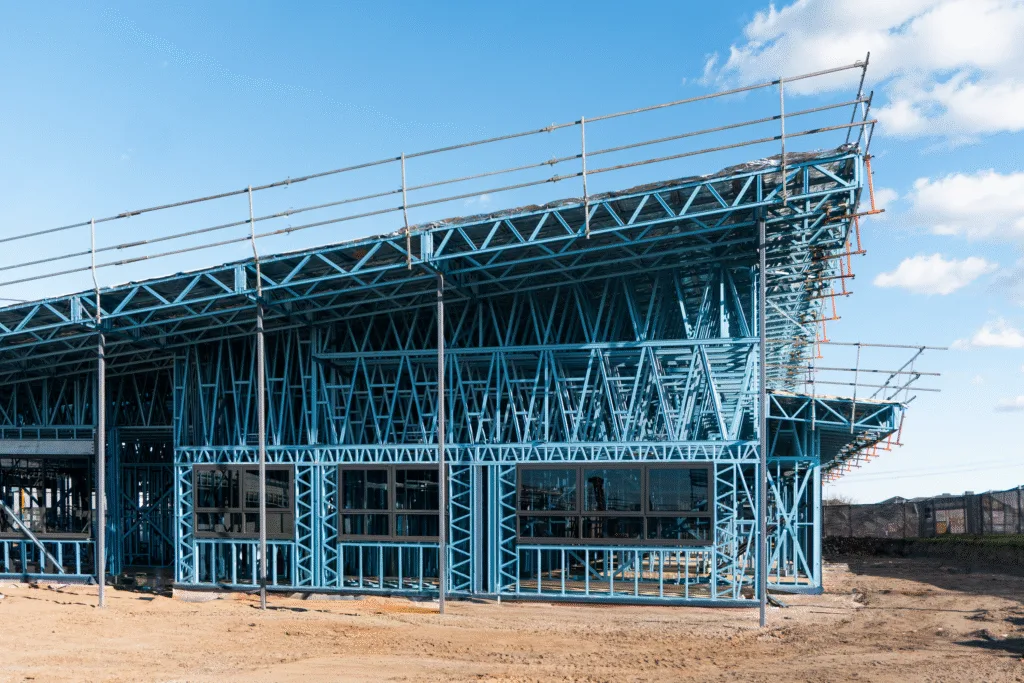

The Aspire Mickleham Childcare Center in Melbourne showcases the future of modern building through the integration of roll forming, steel framing machines, and cold-formed steel (CFS) technology. As part of a new community in the Botanical Village town center, the project highlights how CFS walls, CFS trusses, and modular construction can come together to create precision, safety, and speed in one cohesive build. Through the expertise of ISG Frames and advanced steel framing systems powered by Scottsdale software, this project demonstrates how digital manufacturing and onsite efficiency redefine what’s possible for institutional and educational centers.

ISG Frames fabricated and installed over 5,000 linear meters of TRUECORE® cold-formed steel for the CFS walls and more than 13,000 linear meters for the CFS trusses on the Aspire Mickleham Childcare project. These massive spans required engineering that could only be achieved through advanced roll forming design. The steel framing machines translated digital models into real-world components, automatically cutting, punching, and fabricating each piece. By doing so, the system eliminated manual measuring and minimized material waste, hallmarks of advanced modular steel framing construction. The accuracy of steel framing allowed ISG Frames to preassemble CFS trusses in a controlled environment, guaranteeing exact alignment once they were transported and installed onsite. ISG Frames finished the design, manufacturing, and installation of CFS walls and CFS trusses on this project in just 3 months.

Efficiency was embedded into every phase of this steel framing project. Within the first month, the ISG Frames engineering team detailed the full structure using Scottsdale’s ScotSteel software. Splice joints were tested to confirm their performance under load. The following month focused on steel framing fabrication, where Scotpanel 7090 and Scottruss 6050 roll forming machines produced the prefabricated cold-formed steel members.

Transportable modules were then assembled and shipped, while onsite installation took just four weeks, from CFS wall erection to the crane-lifted CFS trusses. Each activity flowed naturally into the next, proving how modular construction can compress traditional construction timelines without compromising quality.

Learn more at “Overcome Complex CFS Truss Design with New Steel Framing Technology”.

Steel Framed Institutional Childcare Center

Project Type: Institutional Light-Gauge Steel Framing Application, Commercial, Childcare Center

Project Name: Aspire Mickleham Childcare Center

Location: Melbourne, Australia

Steel Fabricator/Customer: ISG Frames

Roll Forming Machine(s): Scotpanel 7090 and Scottruss 6050