Cold-formed steel has become one of the most efficient and reliable materials in modern construction. When fabricated through advanced roll forming machines, it provides precision, speed, and consistency unmatched by traditional framing methods. One critical component within cold-formed steel wall panels is the nogging, a horizontal member that stabilizes vertical studs. Whether applied in wood or steel framing, noggings play a vital role in wall and building performance. By combining the benefits of cold-formed steel and steel framing machines, today’s builders can create stronger, safer, and more efficient wall panels.

What Are Noggings in Cold-Formed Steel Wall Panels?

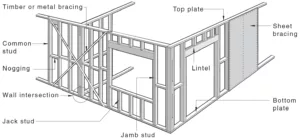

Noggings are horizontal struts within a wall frame, positioned between vertical stud members to increase rigidity and stability. In cold-formed steel wall panels, noggings prevent twisting, buckling, or rotation of the studs. They also help maintain uniform spacing, distribute loads evenly, and resist external forces such as wind and seismic activity. Whether a wall is load-bearing or non-load-bearing, nogging placement is governed by building codes to ensure safety and compliance.

Why Are Noggings Staggered in Cold-Formed Steel Wall Panels?

Staggering noggings is a deliberate practice used in cold-formed steel construction to enhance overall performance. Instead of aligning noggings across the wall, staggering them distributes stresses more evenly, reducing the risk of deformation. This staggered pattern increases load-bearing capacity, minimizes stress concentrations, and improves the fabrication process. In addition, staggered noggings limit the vertical movement of studs, reducing the risk of sagging in cold-formed steel wall panels produced with roll forming machines.

Structural Benefits of Staggered Noggings

Structural Integrity

Cold-formed steel wall panels with staggered noggings gain additional stiffness and stability. This configuration resists buckling under loads and maintains alignment, ensuring long-term durability of the structure.

Fire Safety

Staggered noggings help divide walls into smaller compartments. This compartmentalization slows the spread of fire, increasing the fire resistance of cold-formed steel wall panels and providing occupants more time to evacuate safely.

Energy Efficiency

By breaking up airflow within wall cavities, noggings improve insulation performance. Cold-formed steel walls with properly spaced noggings reduce heat transfer, lowering energy costs in both hot and cold climates.

Noise Reduction

Noggings within cold-formed steel wall panels also enhance acoustics. By increasing the separation between studs, they help dissipate sound waves and reduce transmission, improving sound quality in steel-framed buildings.

How Advanced Roll Forming Machines Improve Nogging Integration

Roll forming machines play a vital role in ensuring accurate and efficient fabrication of cold-formed steel wall panels. Scottsdale’s advanced steel framing machines integrate noggings directly into the design and production process.

Software Integration: The Scottsdale software suite ties nogging placement directly to building codes. During design, it automatically applies nogging spacing based on whether the wall is load-bearing or non-load-bearing.

Precision in Fabrication: Once the wall design is finalized, steel framing machines create cold-formed steel wall panels with exact nogging locations pre-identified by dimples in each member.

Dimpling Technology: Roll forming machines press small indentations, called dimples, into CFS members. These recesses simplify fastening, improve aesthetics, and make steel framing installation faster and more precise.

Ease of Assembly: Because each member is identified and marked during roll forming process, fabricators know exactly where each nogging belongs, reducing errors and speeding up the wall assembly process.

Why Builders Choose Cold-Formed Steel and Roll Forming Technology

Cold-formed steel wall panels produced by roll forming machines are superior to traditional methods because they combine strength, safety, and efficiency. Builders benefit from walls that are easier to fabricate, stronger under load, and more resilient to fire, sound, and energy demands. Staggered noggings further reinforce these advantages, delivering structures that are not only code-compliant but also future-ready.

The Role of Steel Framing Machines in Modern Construction

Noggings may be small components, but in cold-formed steel wall panels, they deliver big results. Staggered placement enhances assembly, load distribution, fire safety, energy efficiency, and sound performance. When paired with the precision and intelligence of advanced steel framing machines, builders achieve wall panels that exceed structural expectations. In today’s construction market, CFS and roll forming are not just efficient; they are essential for safe, sustainable, and high-performing buildings.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Cold-Formed Steel Framing in High-Seismic Regions: All You Need to Know

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Blog – Steel Framing: A Powerful Response to Thermodynamic Challenges

- Blog – Furring Channels: Ultimate Guide to Benefits and Uses

- Blog – A Better Inexpensive Ergonomic Steel Framing Fabrication Process

- Blog – How to Design Cold-Formed Steel Double Top Chord Lintels

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Video – Scottsdale Steel Wall Frame Manufacturing

- Video – Scottsdale 140mm Steel Wall Frame Fabrication

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.