Cold-formed steel (CFS) has become an increasingly popular choice in modern construction due to its lightweight nature, fast installation, sustainability, and compatibility with advanced roll forming technology. As steel framing continues to replace traditional materials across residential, commercial, and modular projects, fire safety has emerged as a critical area of focus, especially for CFS assemblies that incorporate cavities. Understanding the fire performance of CFS is essential for ensuring code compliance and life safety.

Recent research efforts have been dedicated to evaluating the structural behavior of CFS under elevated temperatures, including distortional buckling and the effectiveness of fire-rated assemblies. Leading institutions such as the University of Queensland (UQ), Queensland University of Technology (QUT), and the National Association of Steel Framed Housing (NASH) are actively conducting fire testing on cold-formed steel framing systems. Scottsdale Construction Systems has played a key role in supporting these initiatives, supplying cold-formed steel members, prototypes, and design expertise.

This article explores the latest advancements in fire performance testing, standards development, and engineering strategies for CFS structures.

Properties of Cold-Formed Steel Members Under Elevated Temperatures

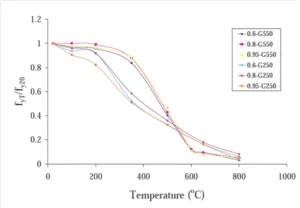

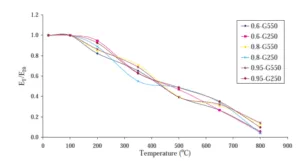

Cold-formed steel loses strength and stiffness when exposed to high temperatures. Material properties such as yield strength, elastic modulus, and thermal conductivity deteriorate significantly around 250°C to 300°C. The figures below show the behavior of material properties under fire conditions for several thicknesses and steel grades.

Yield strength reduction factor with temperature

Source: T. Ranawaka & M. Mahendran 2006

Elasticity modulus reduction factor with temperature

Source: T. Ranawaka & M. Mahendran 2006

Cold-formed steel frames are more sensitive to fire than hot-rolled steel due to thinner sections and higher slenderness. However, they are inherently non-combustible and offer crucial advantages in fire safety in comparison to timber-framed structures.

Steel is far more resilient under fire than lumber, and the degradation of section and engineering properties under fire in steel is much more favorable than that with wood. Learn more about the advantages of steel framing over wood framing. Additionally, cold-formed steel joists will retain 100% of their strength at 200°C and 95% of their strength at 300°C, according to The Steel Construction Institute – SCI Publication P129.

Cold-Formed Steel Columns Subject to Distortional Buckling Under Simulated Fire Conditions

A series of finite element analyses was conducted to study the distortional buckling behavior of CFS compression members under both ambient and elevated temperatures, considering low and high-strength steel with thicknesses of 0.60, 0.80, and 0.95 mm. The analysis results were validated against experimental data and compared with predictions from AS/NZS 4600 and the direct strength method.

At ambient temperature, both design methods provided reasonably accurate predictions, with AS/NZS 4600 performing slightly better. However, at elevated temperatures, the accuracy of both methods declined in some cases, highlighting their limitations outside ambient conditions.

Learn more at Finite Element Analyses of Cold-Formed Steel Columns Subject to Distortional Buckling Under Simulated Fire Conditions.

Recent Research & Testing of Cold-Formed Steel Systems

Extensive fire testing has been carried out globally. Notably, NASH has conducted bushfire testing on cold-formed steel walls and cold-formed steel floors. Scottsdale has taken an active role in supporting fire testing at QUT by contributing design expertise, engineering calculations, and steel frame prototypes.

More recent studies target composite cold-formed steel wall systems, incorporating gypsum board and cavity insulation, in addition to targeting load-bearing cold-formed steel floor joists under fire conditions.

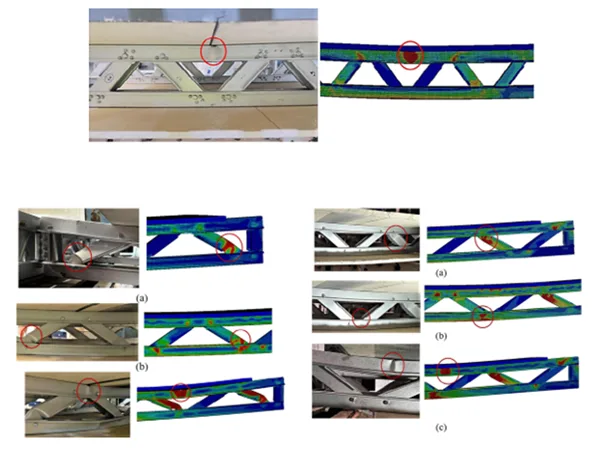

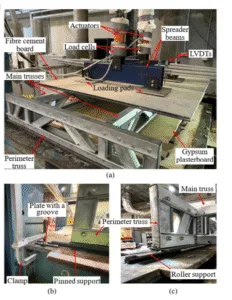

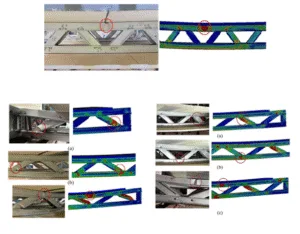

One of the recent projects involving Scottsdale is the full-scale cold-formed steel floor truss testing under fire conditions. This was conducted as a PhD project at QUT with NASH. Scottsdale contributed to this project by supplying the required steel frames and design/engineering knowledge. The figures below display the test setup and procedure.

Scottsdale cold-formed steel floor truss test setup under fire conditions

Source: Ranasinghe et al., 2025

Scottsdale cold-formed steel floor truss testing vs. numerical analyses under fire conditions

Source: Ranasinghe et al., 2025

Other than the physical testing, advanced analysis software can be used to investigate the fire performance of CFS systems. Coupled thermal-structural finite element simulations using platforms such as ABAQUS and SAFIR are now standard tools for accurately predicting cold-formed steel fire performances.

Cold-Formed Steel Fire-Rated Assemblies

What are fire-rated assemblies? Fire-rated assemblies are components of a building that are designed to contain fire and prevent its spread. These assemblies are essential for life safety and property protection in various types of buildings, including residential, commercial, and industrial structures. They are tested and rated based on their ability to withstand fire exposure for a specified period of time.

The Fire Resistance Level (FRL) of cold-formed steel walls are significantly influenced by cladding materials and cavity insulation strategies. FRL is reported by three numbers of SA/INT/INS.

Structural Adequacy (SA) – is the measure of a tested assembly which is load-bearing or carries a predetermined load during fire conditions. This is generally relevant for wall systems.

Integrity (INT) – is the measure of a test assembly to restrict the passage of flames and hot gases. This does not include smoke leakage.

Insulation (INS) – is the measure of the temperature rise on the non-exposed, or non-fire side, of a fire-resistant separating barrier.

When an assembly has a 60/60/60 FRL, it means each element passed the fire test for that number of minutes. Common approaches to achieve 60/60/60 or 90/90/90 FRLs in CFS assemblies include:

- Double-layered Type X gypsum plasterboards

- Mineral wool insulation to enhance thermal protection

- Careful detailing at junctions to prevent thermal bridging and premature failure

Cold-Formed Steel Code Updates and Standards

- The updated AS/NZS 4600 and AISI S100 integrate more specific fire-related provisions for cold-formed steel system

- NASH Bushfire Standard (Australia) provides cold-formed steel specific guidance for bushfire-prone areas. The NASH standard for steel framed construction in bushfire areas, 2021 edition, provides a deemed-to-satisfy (DTS) solution for structures located in bushfire-prone areas. This standard offers detailed construction guidelines for steel-framed homes, including options for different Bushfire Attack Levels (BAL).

- There are ongoing efforts to align cold-formed steel construction practices with performance-based fire engineering requirements as outlined in both the National Construction Code (NCC) of Australia and the International Building Code (IBC) of the United States. These efforts aim to ensure that fire safety designs for buildings using cold-formed steel are not only code-compliant but also optimized for real-world performance. This includes the development of advanced modelling techniques, material testing, and validation studies to assess structural performance under fire conditions, thereby supporting more flexible and innovative CFS system design solutions.

- Steel Framing Industry Association (SFIA) offers multiple resources on how cold-formed steel assemblies perform when faced with fire and thermal challenges. These resources include:

Going Deeper

Evaluating Post-Earthquake Fire Performance of Cold-Formed Steel Framing

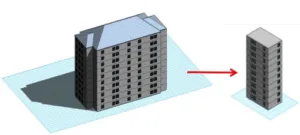

As part of the CFS-NHERI research program, a full-scale 10-story cold-formed steel building, which was previously subjected to earthquake simulations, is exposed to live fire to investigate how prior seismic damage affects fire performance. The structure, representative of real-world mid-rise cold-formed steel construction, includes steel framed shear walls, tie-down systems, and architectural finishes. The fire testing aims to simulate post-earthquake fire scenarios, capturing how elevated temperatures interact with already-compromised structural components, such as deformed studs and degraded fasteners. Researchers monitor the thermal and structural response in real time, focusing on factors like temperature distribution, load path behaviors, and failure mechanisms under combined fire and seismic hazards.

Conceptual Sketch of CFS-NHERI 10-Story CFS-Framed Archetype (left) and Text Building (right)

Source: Johns Hopkins Library

This test is one of the first of its kind to explore multi-hazard resilience in cold-formed steel-framed mid-rise buildings. The findings will inform whether current fire-resistance design standards, such as those in AISI S100 and AISI S400, remain adequate for structures that have experienced prior seismic loading. Results are expected to guide future improvements in detailing, insulation strategies, and connection design for enhanced fire performance. Overall, this research contributes essential data for advancing structural safety and code development in CFS construction.

Learn more by reading Structural Design Narrative of the CFS-NHERI 10-Story Test Building for Multi-Dimensional Shake Table Testing.

Opportunities in Cold-Formed Steel Fire Design and Research

The field of cold-formed steel fire design presents exciting opportunities for advancement, as several key knowledge gaps invite further research and innovation. Areas such as thermal bowing behaviour, connection performance under fire conditions, and system-level responses of CFS assemblies remain ripe for exploration. Additionally, the fire performance of hybrid structural systems, such as cold-formed steel combined with cross-laminated timber (CLT) or concrete slabs, offers promising potential for more resilient and sustainable construction solutions. By exploring these fields, researchers and engineers can strengthen the safety, versatility, and broader adoption of CFS in fire-resilient building design.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How Steel Framing Delivered a Safer Ski Resort in Argentina

- Blog – Steel Homes: An Affordable Solution to the Housing Crisis

- Blog – Comparing Steel vs Wood Framing: Why Steel is Better

- Video – STALART: How to Create Construction Innovation with Innovative Roll Formers

- Video – Welcome to Scottsdale: Discover Our Ecosystem

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.