Cold-formed steel framing is a precision-driven system that allows for efficient, lightweight, and durable structural solutions across residential, commercial, industrial, and modular construction. As part of the steel framing design process, openings must often be incorporated to accommodate services such as plumbing, electrical wiring, or structural connections. These openings are integral to both the functionality and buildability of steel structures and are best achieved through automated roll forming steel framing machines. Scottsdale’s roll forming machines are equipped to create several types of pre-engineered openings, namely plumbing holes and service holes.

Each type of opening serves a unique function in the construction process. Understanding the differences between them is crucial for designers, fabricators, and engineers who use cold-formed steel framing to ensure compliance, efficiency, and structural performance.

Plumbing Holes in Cold-Formed Steel Framing

Plumbing holes are larger, pre-punched openings formed in the web of a cold-formed steel framing member. Their primary purpose is to allow water supply lines, waste pipes, and vent stacks to pass through the steel framing without the need for manual drilling or on-site modification of the cold-formed steel member.

For example, in a 90mm (3.5”) C-section, a plumbing hole might measure 102.6mm x 65mm (4.03” x 2.55”). Plumbing hole dimensions are determined based on both the size of the framing member and the applicable building codes. Larger plumbing holes are possible but must be engineered to ensure the structural capacity of the steel framing is not compromised.

Scottsdale offers plumbing hole capability on its Scotpanel G1 machines as an optional module. For customers who require both service holes and plumbing holes, the Scotpanel G2 and G3 series of roll forming machines come equipped with both.

Service Holes in Cold-Formed Steel Framing

Service holes are circular, pre-punched openings also located in the web of the C-section profile. These are generally smaller than plumbing holes and are used to route electrical wiring, data cabling, or low-voltage systems through cold-formed steel framing.

Most service holes are 28mm (1.10”) in diameter, but Scottsdale can also accommodate service holes of 34mm (1.33”) in diameter, depending on the grommets available in our customer’s region. Scottsdale’s Scotpanel roll forming machines come standard with service hole functionality, making them ideal for most projects.

Key characteristics of service holes:

- Typically spaced to avoid weakening the structural member.

- Not placed too close to the ends of steel framing members, usually a minimum of 100mm to 150mm from the profile edge.

- Frame grommets are required and often inserted post-production to protect cables from sharp edges.

Differences Between Service Holes and Plumbing Holes

The main difference between service holes and plumbing holes lies in their size, shape, and function. Service holes are typically smaller circular openings, either 28mm or, in some cases, 34mm in diameter. These are designed to accommodate lightweight elements such as electrical wiring and data cables. Because of their smaller size, service holes can be spaced more closely together without compromising the structural integrity of the steel framing member. However, they must not be located too close to the edge of the profile, generally maintaining a distance of 100mm to 150mm from the profile ends.

Plumbing holes, in contrast, are larger and may be rectangular or oval in shape. For example, in a 90mm C-section, a plumbing hole might measure 102.6mm x 65mm. These larger holes allow for the passage of plumbing systems, including supply, waste, and vent piping. Due to their size, plumbing holes require more careful engineering analysis to ensure they do not compromise the strength or stability of the framing member. As such, they are typically positioned less frequently and with greater structural consideration.

The table below summarizes key differences between service holes and plumbing holes.

| Feature | Service Hole | Plumbing Hole |

| Primary Use | Electrical wiring, data cables | Water supply, drain, and vent piping |

| Typical Shape | Circular | Rectangular or oval |

| Typical Size | 28mm (1.10”) or 34mm (1.33”) | Up to 102.6mm x 65mm (4.03” x 2.55”) |

| Structural Consideration | Minimal impact with correct spacing | Must be engineered to meet structural limits |

| Placement Flexibility | Strategically placed during the design phase | Limited to ensure compliance with building codes |

| Roll Forming Machine Compatibility | Standard on all Scotpanel machines | Optional on Scotpanel G1, standard on Scotpanel G2 and G3 |

While all Scottsdale Scotpanel roll forming machines include standard service hole capabilities, plumbing holes are available as an optional feature in Scotpanel G1 machines and as a standard feature in Scotpanel G2 and G3 roll forming machine models.

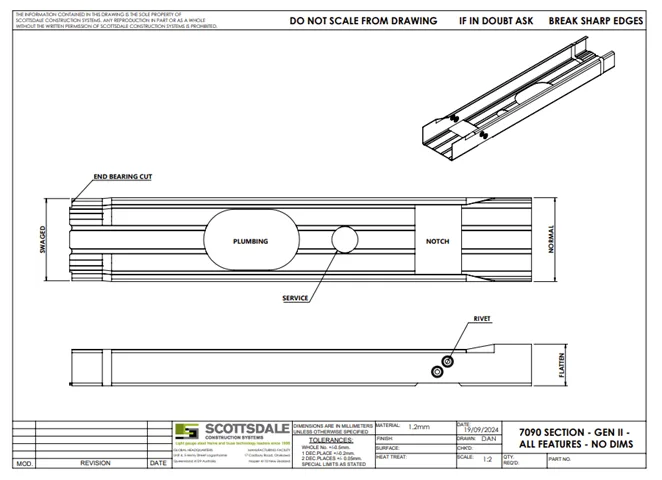

Below shows details of service holes and plumbing holes for the Scotpanel 7090 G2 roll forming machine.

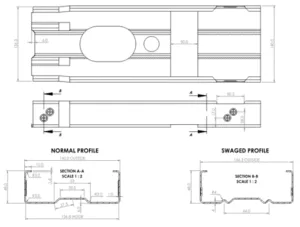

Below shows details for service holes and plumbing holes for the Scotpanel 8140 G2 and G3 roll forming machine.

More details on service hole and plumbing hole sizing are available for each Scotpanel roll forming machine and can be accessed from our technology brochure and compare roll forming systems document.

Engineering Considerations and Customization Options of Openings in Steel Framing

Openings in cold-formed steel framing must be carefully engineered to ensure they do not weaken the structural system. That’s why Scottsdale’s software suite, including ScotSteel and ScotStruct, automatically runs engineering checks on profiles containing service holes and plumbing holes. These tools alert designers if any openings exceed code limits or compromise strength, ensuring every profile is safe, compliant, and ready for construction.

When unique projects demand non-standard hole sizes or layouts, the Scotpanel roll forming machines offer extensive customization capabilities. Our team works directly with customers to understand project requirements and tailor the roll forming machine tooling accordingly. Please contact our sales representatives for additional information.

Contact the Scottsdale Construction Systems Sales and Marketing team by submitting a form, emailing us at sales@scottsdalesteelframes.com, or calling us at +1 (888) 406-2080 (Option 1).

Why Pre-Punched Openings Matter in Cold-Formed Steel Framing

Incorporating pre-engineered openings in cold-formed steel framing offers several key advantages:

- Efficiency: Eliminates time-consuming drilling on-site.

- Precision: Ensures consistent placement that aligns with design intent.

- Safety: Prevents weakening of steel members by avoiding field modifications.

- Integration: Simplifies routing of plumbing and electrical systems.

- Productivity: Speeds up construction timelines without sacrificing quality.

Whether it’s plumbing holes for pipework, or service holes for electrical systems, Scottsdale’s roll forming steel framing machines provide the flexibility and engineering confidence needed for today’s advanced building systems.

Optimizing Openings in Cold-Formed Steel Framing Using Scottsdale’s Roll Forming Solutions

Understanding the different types of openings in cold-formed steel framing is essential for efficient and code-compliant construction. Service holes and plumbing holes each serve a specific purpose and must be carefully designed and manufactured. By leveraging the capabilities of roll forming steel framing machines, such as Scottsdale’s Scotpanel roll forming machines, fabricators can achieve precision, durability, and structural performance in every cold-formed steel member. With built-in engineering checks and customization options, Scottsdale ensures that every opening enhances, rather than compromises, the integrity of cold-formed steel framing.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Roll Forming Process: A Complete Guide to Metal Forming

- Video – Welcome to Scottsdale: Discover Our Entire Ecosystem

- Video – Scotpanel Roll Forming Machines

- Download – Scotpanel Roll Forming Machine Openings

- Download – Scotpanel 8140 G2/G3 Cold-Formed Steel C-Section

- Download – Scotpanel 7140 Cold-Formed Steel C-Section

- Download – Scotpanel 5090 Cold-Formed Steel C-Section

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.