Setting up a new steel framing shop requires more than just investing in advanced roll forming machines; it takes careful planning, strategic layout, and a deep understanding of the cold-formed steel fabrication process. Whether your goal is to produce linear steel framing components, panelized wall and truss systems, or fully modular steel-framed units, your steel fabrication shop floorplan must be designed around your space, goals, equipment, and workflow. Optimizing your steel fabrication shop floorplan for peak roll forming performance is essential to achieving efficiency, safety, and scalability. In this article, we walk through how to design an efficient steel framing operation from the ground up.

What to Consider When Planning Your Steel Framing Shop

Before laying out the factory floor, shop owners must first determine the type of steel framing shop they are operating. Is the focus on producing metal stud and track in bulk, assembling complete wall panels and trusses, or fabricating entire cold-formed steel structural modules? The answer will influence not only the space needed but also how your roll forming machines and cold-formed steel systems are configured.

Key factors to consider when planning include:

- Number and type of roll formers (Scotpanel and Scottruss roll forming machines)

- Available floor space and shop dimensions

- Coil storage and handling method (e.g., forklift, crane)

- Required staff and workflow per station

- Storage for tools and final products

- Electrical requirements and emergency safety access

The steel fabrication shop floorplan will need to account for the production process from coil storage to final product staging, ensuring an efficient and safe flow of operations throughout the steel framing shop.

Key Sections of a Steel Fabrication Shop Floorplan

A well-planned steel framing shop typically consists of five main stations:

Coil Storage Station

This is where steel coils are stored before entering the roll forming machines. It must be easily accessible by forklifts or cranes and provide clear paths for movement. Depending on shop size, coil storage may need to accommodate several tons of steel, safely and securely.

Roll Former Stations

Each roll forming machine, whether it’s a Scotpanel or Scottruss, requires its own workstation. Each machine is typically operated by one person, with two additional workers for assembling panels or trusses. Roll forming machines must be spaced to allow free movement, prevent interference between crews, and provide access to the emergency stop within one meter of the operator.

Roll-Out and Assembly Stations

At the end of every roll forming machine is a roll-out table or roll-out stand, where the cold-formed steel members exit the machine. These tables are used for stacking, labeling, or direct assembly. When long members are fabricated, secondary roll-out tables or roll-out stands can be added to provide extra support and workspace.

Final Product Storage Station

This zone holds the complete cold-formed steel wall panels, trusses, or steel framing components ready for delivery or installation. The area should be strategically placed to minimize handling and allow easy loading onto trucks or containers.

Tool and Equipment Storage Station

Steel framing shops must also house essential tools, such as rivet guns, bolts, fasteners, hand tools, and safety equipment. These items must be stored securely and accessibly. Centralizing tool storage near assembly zones improves productivity and safety.

Personnel and Workflow Recommendations

Efficient cold-formed steel fabrication depends on skilled personnel and a streamlined workflow. Typically, each roll forming machine will have one operator managing the software and machine output, supported by two workers on assembly, rivet installation for panels, or bolt assembly for trusses.

To learn more about this topic by reading our blog “All You Need to Know About Rivets vs. Screws”.

A major benefit of Scottsdale’s roll forming machines is their ability to support single-sided assembly. Wall panels and trusses do not need to be flipped during fabrication, which not only improves assembly speed but also significantly reduces floor space requirements. This approach is particularly beneficial for small shops and mobile factory setups.

Our rivet stands have been a trusted solution in steel framing fabrication for decades, proving their reliability across a wide range of environments. Whether used on the factory floor or in challenging field conditions, such as deserts, gravel lots, uneven terrain, high-rises, confined spaces, military camps, or even boats, these stands deliver consistent performance. Designed for flexibility, each rivet stand is easily adjustable to suit the specific cold-formed steel system being used in the fabrication process. Their mobility and durability make them an essential tool for any steel framing shop aiming to streamline cold-formed steel fabrication both on-site and off-site.

To learn more about effective staffing and assembly workflows, see our article “Best Advice from Steel Framing Shops to Implement Today.”

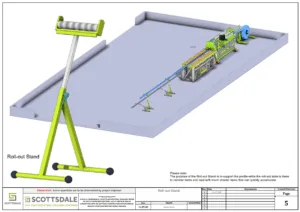

Space-Saving and Efficiency with Roll-Out Stations

Each roll forming machine is paired with a roll-out table, which is typically fabricated during Scottsdale’s hands-on training program with customers. These tables are critical for supporting the cold-formed steel members as they exit the roll forming machine, ensuring proper stacking, labeling, and handoff to assembly crews. Roll forming machines can also be paired with roll-out stands or the combination of both, depending on the steel framing member’s final length. The purpose of the roll-out stations are to support the cantilever of a long member from tilting while 95% of the cold-formed steel element is resting securely on the roll-out table to be labelled and stacked.

Roll Forming Roll-Out Tables

Roll-out tables are best for fixed shop floors and can be extended with a secondary table for long members. When two roll-out tables are in use, the second table can double as a utility bench when not in use.

Roll Forming Roll-Out Stands

Roll-out stands are ideal for mobile setups or shops with space constraints. They are compact, portable, and effective at supporting the tail end of long steel members without occupying permanent space.

These components can be used with both Scotpanel and Scottruss roll forming machines, providing versatile support for any steel framing workflow. For more details and plans on how to fabricate or use roll-out systems, check Scottsdale’s KnowledgeBase or reach out to our sales team.

Scottsdale Construction Systems has a large library of cold-formed steel detailing documents and roll forming documents available on our KnowledgeBase platform.

For more cold-formed steel design insights visit us at https://knowledge.scottsdalesteelframes.com/.

Smart Storage and Safety in Cold-Formed Steel Fabrication

Proper storage is essential not only for tools and fasteners but also for maintaining safety on the steel fabrication shop floor. Items such as rivets, bolts, rivet guns, measuring equipment, and assembly jigs should be stored in a secure central area, preferably close to the assembly zone, to reduce downtime.

Safety is a major priority in every cold-formed steel operation. For every roll forming machine, operators must always remain within one meter of the emergency stop button, especially when running long members. Shop layouts must include clear walkways, emergency access, and ample lighting.

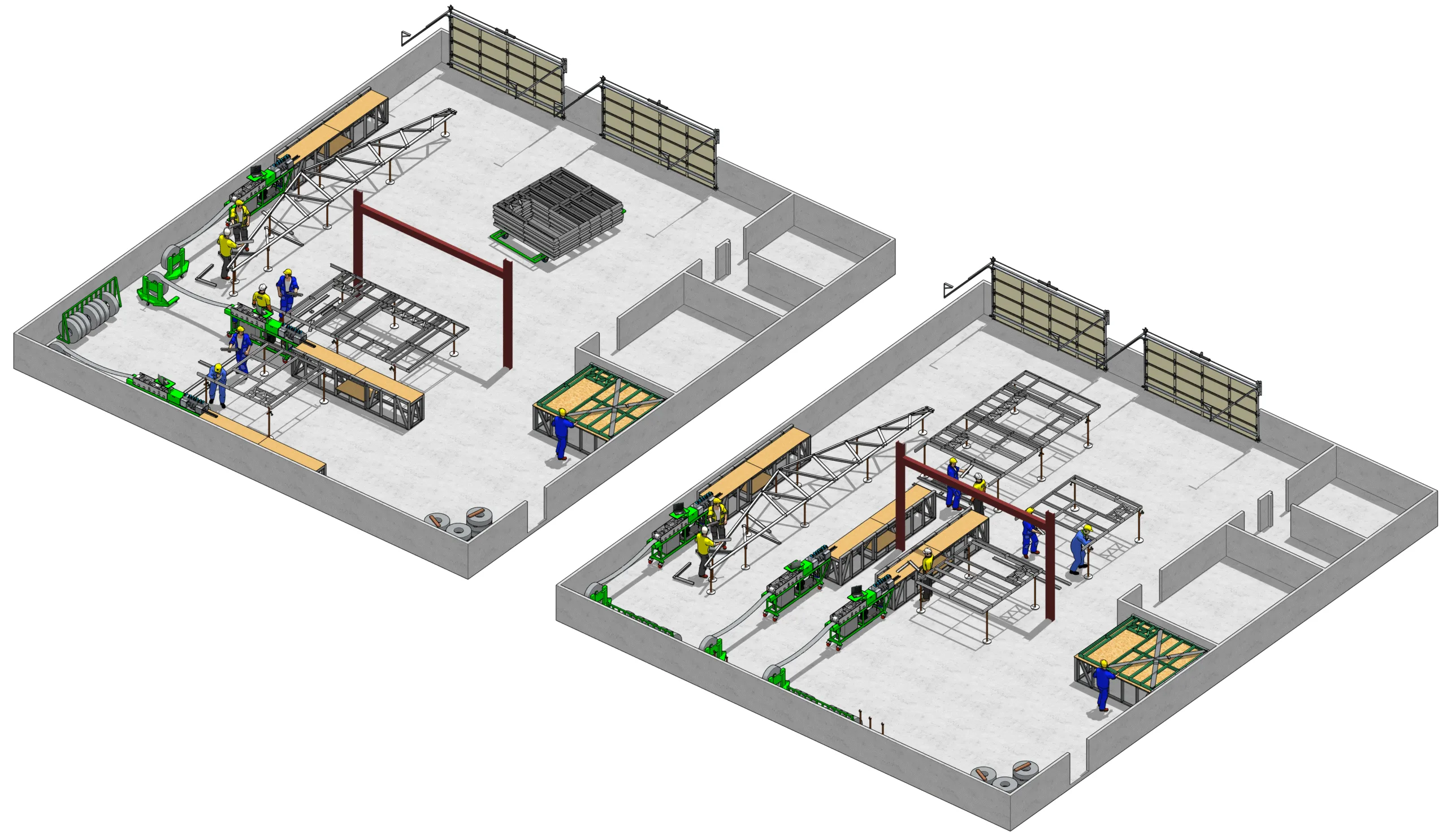

Sample Layouts for Different Shop Sizes

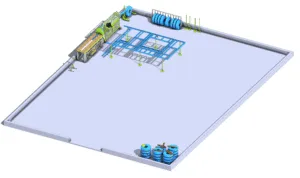

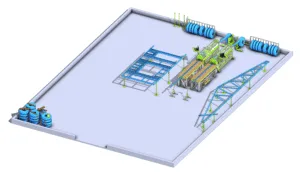

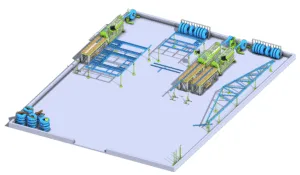

Your steel framing shop can be customized based on your operation size and number of roll formers. Below are simplified examples of typical steel framing shop floorplans. The proposed steel framing shop is 20 meters (65 ft.) by 15 meters (49 ft.).

Operating a Single Roll Forming Machine – Includes coil storage, one roll former with a roll-out table, a small assembly area, and a final product staging zone.

Operating Two Roll Forming Machines – Adds a second roll forming machine and duplicates assembly space, requiring wider aisles and shared tool storage.

Operating Three Roll Forming Machines – Designed for high-volume operations with separate zones for cold-formed steel panels and trusses. Includes optimized coil handling, multiple roll-out systems, and crew flow management to prevent overlap and bottlenecks.

All layouts are designed to be modular and scalable, with emphasis on maximizing productivity per square meter while ensuring safe and efficient steel framing operations.

Our customers can also frame their own steel framing shop using their new roll forming machine(s). Below are images of a model showcasing how customers can fabricate their shop.

Build Your Steel Framing Shop with Confidence

Setting up a steel framing shop is a strategic decision that requires attention to detail, space utilization, staffing, and equipment integration. With the right layout, optimized roll forming machines, and a clear understanding of the cold-formed steel roll forming process, shop owners can maximize productivity, reduce waste, and streamline their steel framing workflow.

Scottsdale Construction Systems supports customers from planning to operation, providing:

- Factory layout services tailored to your floorplan,

- Coil management and handling advice,

- Personnel planning recommendations,

- Electrical and safety guidelines,

- Custom training during machine delivery,

- And far more.

We help our customers transform their vision into a functional, high-performance steel fabrication shop and floorplan, whether you’re outfitting a single roll forming machine or building a full-scale steel framing factory.

Get your personalized steel framing manufacturing shop floorplan models based on your space by contacting the Scottsdale sales team today.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Maintain Critical Components in a Roll Former Assembly

- Blog – Unlocking New Potentials with Cold-Formed Steel & Roll Forming

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Video – Sensational Hotel Fabricated with the Scotpanel 7090 Roll Forming Machine

- Video – Fast and Easy Riveting in Cold-Formed Steel Framing

- Services and Support

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.