When customers invest in a Scottsdale roll forming machine, they’re not just purchasing equipment, but they’re gaining a partner committed to their long-term success. For us, delivery is just the beginning. That’s why we offer hands-on training for every roll forming machine, focused on building confidence in cold-formed steel framing. Our comprehensive training program ensures that every customer can confidently fabricate cold-formed steel framing using their new roll forming machines, whether it’s walls, trusses, floors, or architectural components.

This article highlights the training process, which forms a critical part of our two-week, in-person program conducted at the customer’s location. It’s designed to give each team the technical skills, confidence, and practical experience needed to bring their cold-formed steel projects to life.

Customized Roll Forming Machine Training for Steel Framing Success

Every customer’s business is unique, and so is our training. Once the Scottsdale roll forming machine arrives, our expert trainers begin a hands-on setup process, working side by side with the customer’s team. This is not a one-size-fits-all approach, but training is curated based on the steel framing machine(s) purchased, the customer’s production goals, and the level of experience on-site.

From day one, our trainers guide users through everything from safe machine setup to efficient steel framing techniques. Initial sessions focus on understanding the roll forming machine itself, learning the controls, understanding the material flow, mastering the decoiler loading and unloading process, and troubleshooting with confidence.

Setting Up Steel Framing Machines for Real-World Fabrication

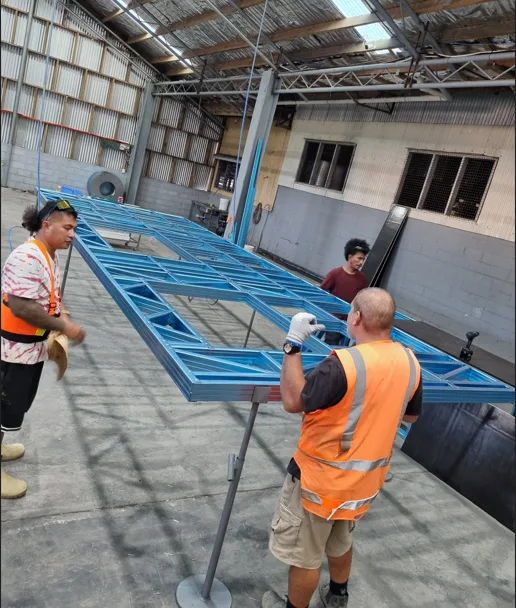

One of the first fabrication exercises during training is building a steel roll-out table using the roll forming machine. Nearly every cold-formed steel shop needs a roll-out table, and it’s a perfect first project to reinforce basic steel framing principles, riveting techniques, and fabrication tips.

This roll-out table build allows our trainers to teach new customers how to form cold-formed steel members, how to operate the roll forming machine, and how to rivet with speed and precision. These skills are essential for steel framing operations and provide a foundation for more advanced training throughout the two-week period.

Cold-Formed Steel Structures: From Machine Training to Construction

Once customers are confident in roll forming machine operation and fabrication basics, we take training a step further, outside the classroom and into the real world. If the customer is ready and willing, our trainers will help them fabricate small-scale cold-formed steel structures as part of their hands-on education.

In one case, a customer’s initial project was an actual tiny steel-framed structure. Using their new Scotpanel roll forming machine, our trainers helped fabricate a complete steel-framed tiny unit right on their property.

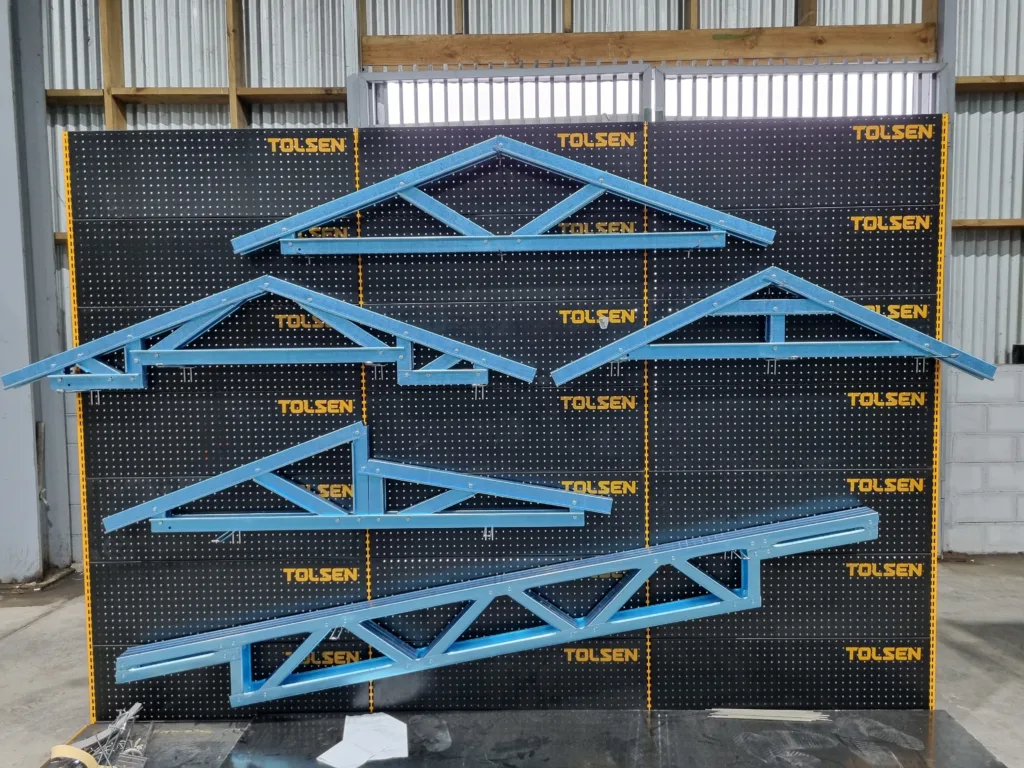

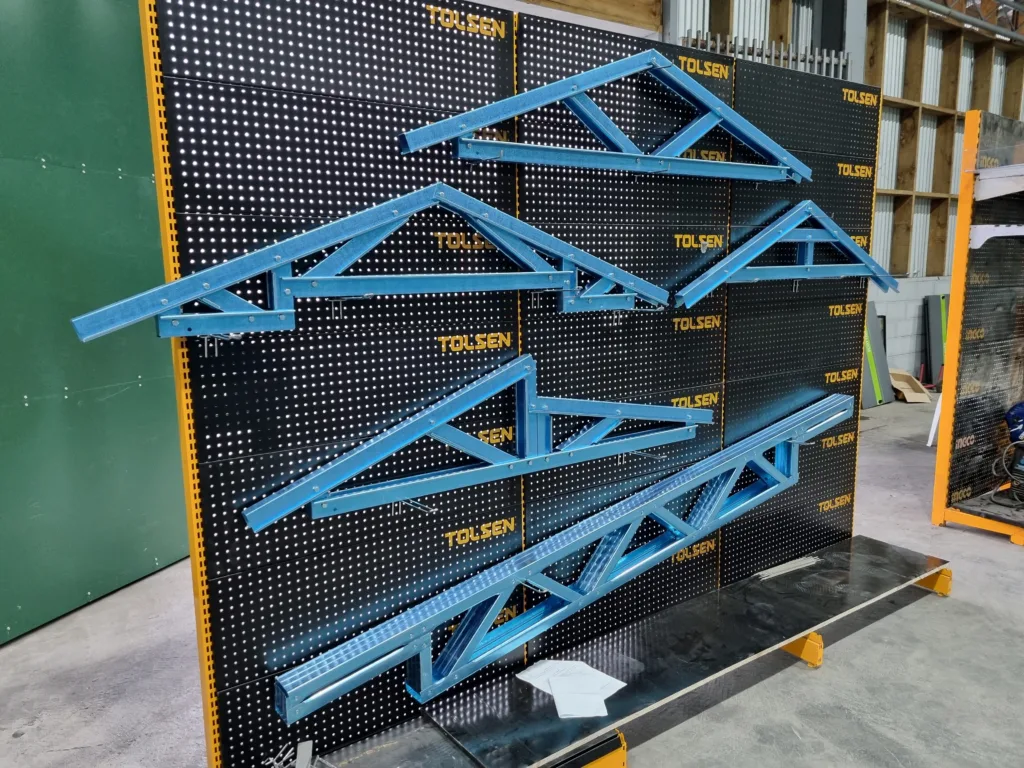

Steel Trusses and Showroom Samples with Roll Forming Machines

Customers purchased a Scottruss roll forming machine focused their training on truss systems. Our team helped design and fabricate five distinct steel truss models using hat-section profiles, which were later displayed in their showroom. These scale truss samples became invaluable marketing tools, allowing clients and project owners to see and touch examples of what’s possible with cold-formed steel and roll forming technology.

Display models are a simple yet effective way to communicate structural capabilities to project owners. They allow anyone who visits the shop to take a truss model home, to a meeting or office, with a project owner for visual reference.

Beyond Buildings: Custom Cold-Formed Steel Fabrication Projects

Our training doesn’t stop at standard structural components. Depending on the customer’s goals, our trainers have also helped fabricate non-building elements, including custom steel desks and display pieces. These versatile small training projects help customers explore new product offerings, expand their services, or furnish their own operations, all while learning essential steel framing fabrication techniques.

Essential Skills for Roll Forming and Steel Framing

Throughout the two-week roll forming training, Scottsdale customers develop a comprehensive understanding of cold-formed steel framing and how to use roll forming machines effectively. Topics include:

- Safe machine setup and operation

- Loading and unloading the steel decoiler

- Efficient riveting techniques

- Proper bolting and fastening of steel trusses

- Fabrication of wall panels, floor joists, and roof trusses

- Assembly of K-bracing and X-bracing for lateral load resistance

- Techniques for framing around doors, windows, and other openings

- Understanding full system integration of cold-formed steel framing components

This immersive learning approach empowers our customers to design, fabricate, and erect small-scale structures independently. Whether they’re working on residential steel framing, commercial builds, or modular construction, our goal is to leave every team equipped to hit the ground running.

Ongoing Support for Roll Forming Machines and Steel Framing Operations

While the on-site training may last two weeks, Scottsdale’s commitment to customer success is ongoing. After the initial training, our global support team remains available 24/7. Customers can reach us through email, submit a help ticket, or access our robust online KnowledgeBase filled with tutorials, technical documents, and troubleshooting guidelines. No matter where our customers are in the world, help is always just a few clicks away. Whether it’s a technical question, a software update, or a production challenge, we’re here to ensure their journey continues smoothly.

Join the Scottsdale KnowledgeBase community to learn more about steel framing design and roll forming technology.

Training for Cold-Formed Steel Framing Success

Cold-formed steel construction offers tremendous advantages in speed, durability, and precision. But realizing these benefits requires more than just the right roll forming machine; it takes the right training. That’s why Scottsdale’s roll forming training program is so vital. It empowers our new customers to do more than operate a machine; it helps them launch or scale a business built on best practices, technical know-how, and real-world performance.

From building steel roll-out tables to custom roof truss models, from riveting basics to full structure fabrication, our training delivers the hands-on experience needed to master steel framing. And we’ll be there every step of the way, long after the training ends. Because at Scottsdale, we don’t just deliver roll forming machines, we deliver long-lasting capability.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Best Advice From Steel Framing Shops To Implement Today

- Blog – Empowering New Steel Framing Businesses From Startup to Success

- Video – Commissioning & Training Process for Knudson by Scottsdale KFS Framemaker 1622 G1 Roll Forming Machine

- Video – How Scottsdale’s Roll Forming Technology and Software Support Business Growth

- Video – Scotpanel Roll Forming Machine Double-Rivet Joint Functionality

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.