Shaft walls play a critical role in multi-story buildings by enclosing vertical openings while maintaining life-safety separation. Shaft wall framing is commonly executed using steel framing fabricated by roll forming machines. Integrated cold-formed steel studs and J-tracks following UL assemblies designed to achieve a tested fire rating are all key elements of shaft walls. Together, these elements allow shaft walls to perform as continuous, code-compliant fire and smoke barriers across multiple floors in a steel-framed building.

What are Shaft Walls?

A shaft wall is a vertical, fire-resistant wall assembly used to enclose building shafts such as elevator hoist ways, stairwells, mechanical ducts, and plumbing risers. These shaft walls prevent fire and smoke from traveling between floors while protecting essential building services. Because vertical openings can act like chimneys during a fire, shaft walls are a fundamental requirement for achieving the required fire rating in multi-story structures.

Shaft Walls Primary Purpose:

- Contain fire and smoke between floors

- Maintain compartmentalization for life safety

- Protect critical vertical services

- Meet building code fire-resistance requirements

Common applications of shaft walls include elevator shafts, stair walls, duct enclosures, and corridor ceiling transitions. In each case, shaft wall framing ensures continuity and durability where floor assemblies are penetrated.

Shaft Wall Components and Shaft Wall Framing Systems

A complete shaft wall framing system consists of cold-formed steel stud profiles, track profiles, fire-rated shaftliner panels, exterior gypsum layers, approved joint/connection treatments, and sealants. These components work together to deliver an approved fire-rated system while maintaining structural stability.

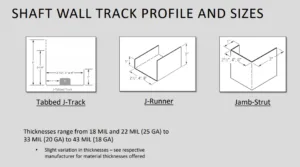

Stud profiles used in shaft wall framing typically include CT-profiles, I-profiles, CH-profiles, and E-profiles. Track profiles include tabbed J-tracks, J-runners, and Jamb-struts. These components are commonly manufactured using roll forming machines, which ensure consistent dimensions, repeatable tolerances, and reliable performance in steel framing applications.

Key Performance Features of Shaft Walls

The primary performance requirement for shaft walls is fire resistance. Depending on the building design, shaft walls are commonly rated for one, two, or three hours of fire rating. In addition to fire resistance, shaft walls provide smoke containment and structural stability under fire exposure.

Key Performance Features of Shaft Walls:

- Fire resistance: 1-, 2-, or 3-hour rated assemblies

- Smoke containment

- Structural stability under fire exposure

- Compliance with building codes (IBC, UL assemblies, AISI, etc.)

IBC 2021 Chapter 7 – Fire and Smoke Protection

UL 263 – Standard for Fire Tests of Building Construction and Materials

AISI S220 – North American Standard for Cold-Formed Steel Nonstructural Framing

Because steel framing is non-combustible and does not shrink or warp, it allows shaft walls to remain continuous over multiple stories. This dimensional stability supports long-term performance and protects the integrity of the fire rating throughout the building’s service life.

Why Shaft Walls Are Critical to Life Safety

Shaft walls are essential for fire and smoke containment, life-safety protection, and system durability. Building codes require shaft walls to match the fire rating of the floors they penetrate, remain continuous from floor to floor, and use approved fire-tested assemblies. Without compliant shaft walls, a building cannot be legally occupied.

In steel framing construction, shaft walls offer additional advantages. Steel framing remains straight and stable during temperature changes, ensuring that shaft wall framing maintains alignment and fire-resistive performance even in tall structures.

The Importance of J-Tracks in Shaft Wall Assemblies

Within shaft wall framing, J-tracks are horizontal steel channels installed at the top and bottom of the wall, and sometimes at intermediate floors. J-tracks are not decorative elements; they are essential to the performance of shaft walls and the preservation of the required fire rating.

From a fire-resistance perspective, J-tracks provide a continuous boundary at floor and roof lines, capturing shaftliner panels so there are no gaps for flame or smoke migration. Properly installed J-tracks are critical to maintaining the tested fire rating of the assembly.

Fire-Resistance Integrity

J-tracks provide a continuous fire-rated boundary at floor and roof lines. They properly capture shaftliner panels so there are no gaps for flame or smoke migration. Without properly installed J-tracks, the assembly may fail inspection or lose its fire rating.

Structural Support & Load Transfer

J-tracks anchor the shaft wall to the slab above and below. They resist lateral movement from wind or seismic forces and help transfer loads into the building structure. In multi-story cold-formed steel construction, J-tracks ensure the shaft wall remains vertically aligned and stable.

One-Sided Construction Capability

A major advantage of shaft walls is that they can be constructed from one side only. J-tracks make this possible by holding studs and shaftliner panels in place during installation, allowing floor-by-floor erection without backside access. This is critical for stair and elevator cores.

Shaftliner Retention System

In typical shaft wall systems, C-H studs slide into J-tracks. The shaftliner panels are inserted between studs, and the exterior drywall is applied to the accessible side of the system. The J-track acts as the retention channel that locks the system together. Without it, panels cannot remain properly seated.

Movement Accommodation

Properly detailed J-tracks allow for deflection at floor lines, prevent stress cracking in gypsum panels, and maintain fire rating while accommodating vertical movement. This is especially important in steel or concrete structures with live load (LL) deflection.

J-tracks are the foundation and containment system of a shaft wall assembly. They secure the wall, preserve fire ratings, enable one-sided construction, and ensure structural continuity from floor to floor.

Structural Support and Constructability

In addition to fire performance, J-tracks provide anchorage and load transfer within shaft wall framing. They resist lateral movement from wind or seismic forces and help keep shaft walls vertically aligned across multiple floors. This is especially important in high-rise and mid-rise steel framing projects.

J-tracks also enable one-sided construction, a key advantage of shaft walls. Because elevator and stair shafts are often inaccessible from the back side, J-tracks allow shaft walls to be erected floor-by-floor without requiring rear access.

For more details, refer to the full “Shaft Wall Framing” presentation.

Roll Forming Precision in Shaft Wall Components

Modern roll forming technology allows shaft wall components, including J-tracks, to be fabricated with exceptional accuracy. These J-tracks can be roll-formed using KFS Framemaker 1420 roll forming machines. By employing roll forming of steel framing systems in-house, builders achieve consistent quality, faster installation, and dependable fire-rated performance in shaft walls.

Link to KFS 1420 brochure, specification, and other download material.

Shaft Walls are the Foundation of Fire Safety

Shaft walls are a cornerstone of safe, compliant multi-story construction. Through engineered shaft wall framing, non-combustible steel framing, precision roll forming, properly detailed J-tracks, and tested fire rating assemblies, shaft walls protect occupants, preserve egress paths, and safeguard building systems. When designed and fabricated correctly, shaft walls deliver long-term performance and code-compliant fire protection from the ground floor to the roof.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Blog – Fire and Acoustic Ratings in Cold-Formed Steel Assemblies Simplified

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Video – Knudson by Scottsdale KFS Framemaker 1420G1 in Action

- Video – Knudson by Scottsdale Roll-Formers KFS Framemaker 1420 Used to Build an Amazing Church with Cold-Formed Steel

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.