In today’s construction industry, efficiency and adaptability are everything. Companies that succeed are those that can deliver precise steel framing fabrication quickly and cost-effectively. At the heart of this capability are advanced roll forming machines. From wall panels on residential projects to long-span trusses on commercial projects, steel framing has become the backbone of modern building methods. While single-profile roll forming machines remain popular for consistent production, more fabricators are turning to multi-profile roll forming machines to expand their services, increase flexibility, and future-proof their steel framing operations.

Single-Profile Roll Forming Machines

A single-profile roll forming machine is designed to fabricate just one profile. For many businesses, this is the first and most practical entry point into steel framing fabrication. Scottsdale offers two families of roll forming machines in this category: the Scotpanel roll forming machines and the Scottruss roll forming machines.

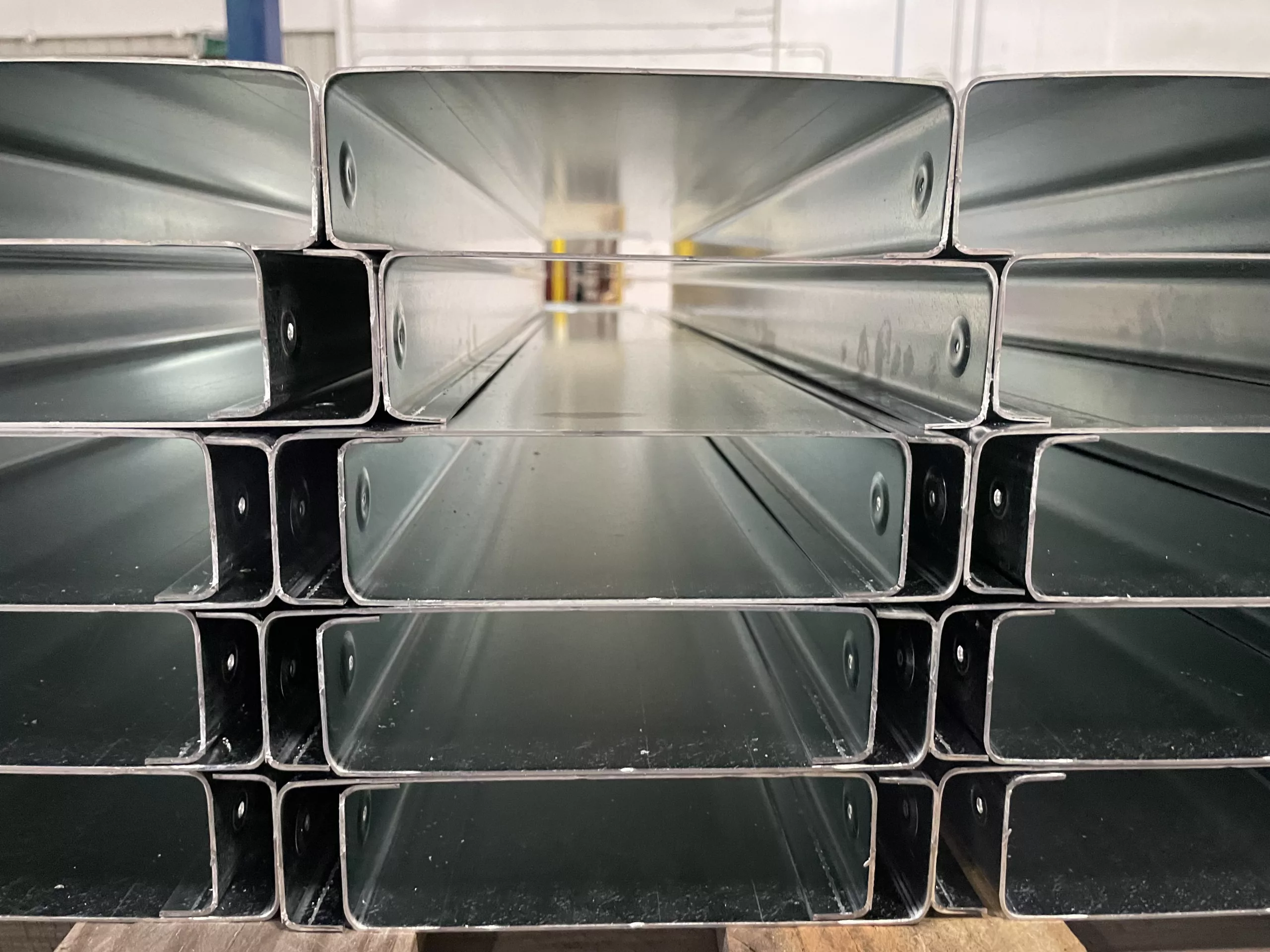

Scotpanel roll forming machines fabricate single-profile C-sections, often used to produce walls, roofs, ceilings, and support frames in low to mid-rise construction. C-sections can also be used in internal and external partition walls in mid-rise to high-rise construction projects. Other applications of C-sections include solar panel support frames and prefabricated internal office fit-outs, and more. Learn more about our family of Scotpanel roll forming machines.

Scottruss roll forming machines fabricate single-profile at-sections, often used to produce roof trusses and floor trusses in a wide variety of projects, from residential to multilevel construction. These Hat-sections can also be used on mezzanine floors and are optimized to carry heavy loads. Learn more about our family of Scottruss roll forming machines.

View the 3D model of cold-formed steel truss types that can be fabricated using steel framing machines.

Single-profile roll forming machines are ideal when production is consistent and focused on a specific market segment. For example, a residential framing company may rely on a single Scotpanel machine for steel framing fabrication day after day, fabricating wall panels, roof, and floor trusses from the same steel framing machine. But as demand grows and projects become more complex, the limitations of single-purpose equipment can become clear.

Multi-Profile Roll Forming Machines

A multi-profile roll forming machine is a powerful solution for companies that need versatility. Unlike single-profile equipment, these roll forming machines can fabricate a wide variety of profiles and dimensions. Scottsdale’s multi-profile roll forming machines include the Knudson by Scottsdale KFD Framemaker and the KFS Framemaker.

These machines are engineered to handle multiple profiles and gauges on a single platform, eliminating the need for several separate machines. Whether you are producing light-gauge panels or heavy-duty trusses, a multi-profile steel framing machine can seamlessly adapt to the project requirements.

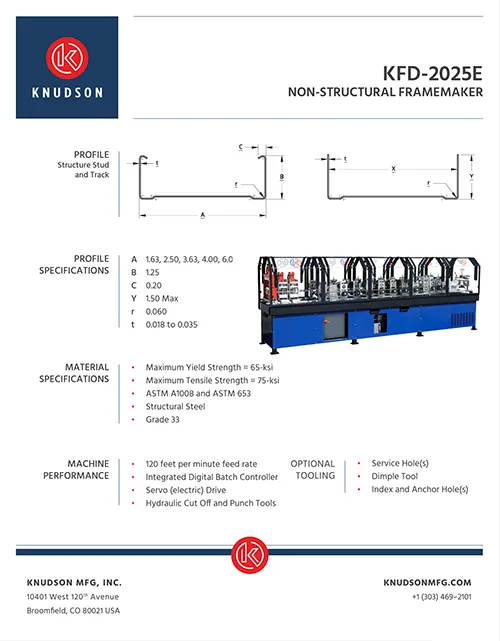

Knudson by Scottsdale KFD Framemaker

The Knudson by Scottsdale KFD Framemaker is a roll former specializing in non-structural cold-formed steel elements and can fabricate lipped and unlipped sections. Applications of these profiles include internal load-bearing and non-load-bearing partition walls, office and shop fit-outs, suspended ceilings, bulkheads, facades, and more.

KFD Framemaker 2025 model produces sections with web dimensions of 1.63, 2.50, 3.63, 4.00, and 6.00 in. with a 1.25 in. flange dimension. The thickness of members ranges from 20 gauge to 25 gauge. Learn more about KFD Framemaker 2025 and the profile details below.

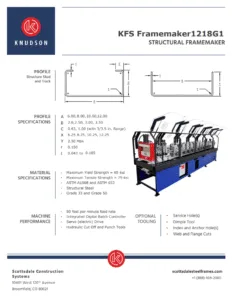

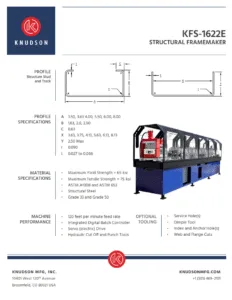

Knudson by Scottsdale KFS Framemaker

The Knudson by Scottsdale KFS Framemaker is a roll former specializing in structural cold-formed steel elements and can fabricate lipped and unlipped sections. Applications of these profiles include internal load-bearing partitions and load-bearing walls on a variety of projects, from residential projects to mid-rise and high-rise buildings. KFS Framemaker family includes three models of multi-profile roll forming machines.

KFS Framemaker 1218 model produces sections with web dimensions of 6.00, 8.00, 10.00, and 12.00 in. with flange dimensions of 2.00, 2.50, 3.00, and 3.50 in. The thickness of members ranges from 12 gauge to 18 gauge. Learn more about KFS Framemaker 1218 and the profile details below.

KFS Framemaker 1420 model produces sections with web dimensions of 3.63, 4.00, 6.00, 8.00, 10.00, and 12.00 in. with flange dimensions of 1.63, 2.00, and 2.50 in. The thickness of members ranges from 14 gauge to 20 gauge. Learn more about KFS Framemaker 1420 and the profile details below.

KFS Framemaker 1622 model produces sections with web dimensions of 3.50, 3.63, 4.00, 5.50, 6.00, and 8.00 in. with flange dimensions of 1.63, 2.00, and 2.50 in. The thickness of members ranges from 16 gauge to 22 gauge. Learn more about KSF Framemaker 1622 and the profile details below.

Below are the top five reasons to invest in Knudson by Scottsdale multi-profile machines.

#1 Multiple Steel Framing Profiles in One Machine

The biggest advantage of a multi-profile roll forming machine is right in the name: multiple profiles. With the ability to produce up to six different shapes, these machines consolidate production that would otherwise require several single-purpose machines. The result? Lower equipment costs, reduced floor space, and faster transitions between production runs, all critical benefits in a competitive steel framing fabrication environment.

#2 Steel Framing for Multi-Story Construction

When constructing buildings above three floors, steel framing fabrication must meet higher structural demands and stricter design requirements. A multi-profile roll forming machine ensures compliance with structural codes and provides the robustness needed for large-scale jobs. This capability positions your company to compete for and win bigger contracts in the growing market for mid-rise and multi-story projects.

#3 Roll Forming Machines with Flexible Gauges

Every steel framing project demands different material thicknesses. While some designs call for heavier steel, others need lighter gauges for efficiency. With a multi-profile roll forming machine, you can run gauges lower than 16, broadening the types of jobs your shop can accept. This flexibility reduces outsourcing costs and ensures you never have to turn down a client due to equipment limitations.

#4 Be Ready for Any Steel Framing Fabrication Job

Versatility equals opportunity. A multi-profile roll forming machine allows you to confidently accept a wider variety of contracts, whether for residential, commercial, or industrial projects. This adaptability ensures your shop is always ready to meet evolving market needs, from light partition walls to heavy roof trusses. With fewer limitations, your business can focus on growth, customer satisfaction, and long-term success.

#5 Future-Proof Investment in Roll Forming Machines

Investing in steel framing machines is a significant decision, and choosing the right system has long-term implications. A multi-profile roll forming machine reduces the need for multiple purchases, lowers maintenance expenses, and simplifies operator training. As construction demands shift, your equipment will already be capable of producing new profiles and gauges, making it a future-proof investment for your steel framing fabrication operations.

Comparing Single vs. Multi-Profile Roll Forming Machines

The decision between single-profile and multi-profile roll forming machines often comes down to the scale and variety of projects. For small shops or startups, the Scotpanel and Scottruss offer efficient, focused production for consistent steel framing fabrication. But for companies handling diverse projects or seeking long-term scalability, the KFD Framemaker and KFS Framemaker provide unmatched flexibility.

By centralizing operations into one multi-profile roll forming machine, companies reduce costs, save valuable shop space, and gain the ability to adapt quickly to changing project demands. In today’s fast-moving construction landscape, staying competitive requires more than efficiency; it requires adaptability. Multi-profile roll forming machines give fabricators the flexibility, strength, and range needed to take on complex steel framing projects without hesitation. For businesses looking to scale, diversify, and future-proof their operations, investing in a multi-profile roll forming machine is not just a choice; it’s a strategic move toward long-term success in steel framing fabrication.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Blog – Unlocking New Potentials with Cold-Formed Steel and Roll Forming

- Blog – Expert Tips for Successfully Operating a Roll Forming Business

- Blog – Grow Your Competitive Edge with In-House CFS Fabrication

- Video – Knudson by Scottsdale Roll Forming Machines Used to Build an Amazing Church

- Video – Commissioning and Training Process for Knudson by Scottsdale Roll Forming Machine

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.