When Unipods was featured in Khaleej Times’ Innovation Disruptors series, it wasn’t just recognition for one company; it was a showcase of how advanced roll forming machines are reshaping the modular construction industry. By integrating Scottsdale Construction Systems’ roll forming technology into their manufacturing process, Unipods delivers high-quality modular solutions through efficient off-site manufacturing and streamlines prefabricated construction, setting a model for how the industry can build faster, smarter, and more sustainably.

Image source for all graphics: Khaleej Times

Building Smarter with Advanced Roll Forming Machines

Founded to reimagine construction through modular solutions, Unipods has become a pioneer in prefabricated modern construction across the UAE. The company identified a critical gap in delivering bathroom pods and kitchen pods with consistent quality during the region’s construction boom. The solution was clear: shift from traditional site-based methods to off-site manufacturing, powered by advanced roll forming machines.

Today, Unipods operates three Scottsdale roll formers including a Scotpanel 7076 and two Scotpanel 7063 machines. These roll forming machines allow them to fabricate cold-formed steel wall panels and sections with unmatched speed and accuracy. Every cold-formed steel C-section is cut, punched, and notched to exact specification, ready for assembly into complete modular units.

A key advantage of Scottsdale’s roll forming technology is its ability to produce precise web openings in C-sections directly during fabrication. In modular bathrooms and kitchens, framing elements must accommodate plumbing, electrical, and mechanical services. Instead of relying on manual drilling or cutting onsite, processes that slow down schedules and create costly errors, the roll forming machines punch web openings at the exact required locations during production.

Producing precise web openings in C-sections ensures:

- No manual cuts or measurements on site.

- Faster, error-free installation of pipes, wiring, and conduits.

- Reduced waste, since each opening is engineered into the section from the start.

- Consistent quality, with every member delivered ready for immediate assembly.

By integrating web openings into the steel framing, Unipods not only speed up modular assembly but also eliminate rework and ensure pods are delivered with the precision demanded on high-volume projects. This seamless workflow is one of the reasons their prefabricated construction process is both faster and more cost-effective than traditional construction methods.

Learn more about this topic by reading our blog “Practical Guide to Web Openings in Cold-Formed Steel Framing”.

Standard and Nonstandard Applications of Roll Forming

The strength of roll forming lies not only in precision but also in flexibility. With Scottsdale’s technology, Unipods can address both standard and nonstandard project requirements in modular construction.

Standard roll forming uses include producing cold-formed steel wall panels, trusses, and framing systems for modular bathrooms, kitchens, and service pods. Nonstandard roll forming uses include custom framing elements and unique architectural features that would otherwise slow down traditional fabrication.

By expanding the scope of roll forming machines beyond just repetitive framing, Unipods can innovate with new modular solutions that maximize material efficiency while reducing waste.

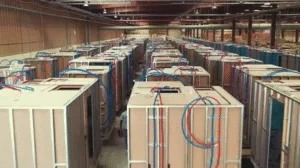

The Power of Off-Site Manufacturing

In traditional construction, every detail of a bathroom or kitchen must be assembled onsite, under time pressure, in less-than-ideal conditions, and often with variable quality. With Scottsdale’s roll forming technology, Unipods fabricates complete pods in a controlled factory environment. This off-site manufacturing process ensures each pod is delivered fully fitted, finished, and ready to install.

Watch the full Khaleej Times video on Unipods.

This approach transforms the building site into an assembly zone rather than a fabrication site. Cranes lift prefabricated pods into place, dramatically reducing onsite labor, cutting project timelines, and improving safety. The efficiency gains make prefabricated construction both faster and more cost-effective.

Sustainability Through Prefabricated Construction

Unipods’ innovation is not just about speed; it’s also about sustainability. Roll forming machines precisely cut steel to length, minimizing offcuts and scrap. In an industry where waste reduction is critical, this precision matters.

In its off-site manufacturing facilities, Unipods aligns with the UAE’s green building initiatives by using recyclable materials, reducing carbon emissions, and ensuring water and energy efficiencies. This makes prefabricated construction an environmentally responsible alternative to conventional methods while still meeting the highest performance standards.

A Model for the Future of Modular Construction

Unipods demonstrates how roll forming technology can unlock the true potential of modular construction. Unipods has delivered:

- 4,175 pods on the Moon Flower City – Moon Flower Real Estate Development LLC, Abu Dhabi, UAE

- 3,441 pods on The Downtown Views II – Emaar, Dubai, UAE

- 1,720 pods on Bluewater Residential – Meraas Holdings, Dubai, UAE

- 1,314 pods on ACT 01 & ACT 02 – EMAAR, Dubai, UAE

- And more

With its combination of speed, accuracy, and versatility, Scottsdale’s system enables companies to explore new modular solutions for housing, healthcare, infrastructure, and beyond. What once seemed ambitious, building entire kitchens and bathrooms off-site and delivering them ready-to-install, is now a proven, cost-effective reality. Unipods has shown that with the right tools, prefabricated construction can scale to meet both regional growth and global housing challenges.

Read the full Khaleej Times article on Unipods at “Revolutionizing Construction: Unipods pioneers the future of modular innovation”.

What Would You Achieve with Advanced Roll Forming Technology?

Unipods’ success story is a testament to what’s possible when roll forming machines and modular construction come together. Scottsdale Construction Systems has provided the technology that helped them become an innovation disruptor, delivering projects faster, at lower cost, and with greater sustainability.

The question is: How could advanced roll forming technology help you become an innovation disruptor?

It’s time to explore the possibilities and join the next wave of modular innovation with Scottsdale Construction Systems.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Launch a Successful Steel Framing Business

- Blog – Power Source Options in Advanced Roll Forming Technology

- Blog – 5 Great Reasons to Use Cold-Formed Steel in Modular Construction

- Blog – Unlocking New Potentials with Cold-Formed Steel and Roll Forming

- Video – Welcome to Scottsdale: Discover Our Entire Ecosystem

- Financial Solutions

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.