At Scottsdale Construction Systems, our mission is to ensure that every customer who invests in our roll forming machines or steel framing machines achieves long-term customer success. We know that advanced technology is only part of the equation. Equally important is the experience customers have with us: from the very first conversation to the day they run their first job, and well into their continued success in steel framing fabrication.

Our seven-phase onboarding process is designed to give every customer a clear path forward. It is not just about installing roll forming equipment; it’s about empowering steel framing businesses with the training, resources, and confidence they need to thrive in a competitive construction market.

Phase 1

Order and Initial Setup for Roll Forming Machines

The journey begins once a customer places an order for roll forming machines. At this stage, confirmation of the order and deposit signals the transition from sales to the customer success team. The sales representative hands over critical details, including order specifications, delivery timelines, and customer expectations, to the dedicated customer success manager.

This handover is not just procedural. It ensures continuity. The customer success manager becomes the main point of contact, helping the customer move seamlessly from contract to setup. By assigning one consistent guide, Scottsdale makes sure no customer feels lost during the early stages of their steel framing journey, ensuring logistics are coordinated, expectations are managed, and decisions are mutually agreed upon.

Phase 2

Customer Account Setup for Steel Framing Success

With the order confirmed, the next step is to establish a customer account within the Scottsdale ecosystem. The customer success manager shares a detailed form that gathers essential information about the customer’s business, team members, and preferred communication methods.

Once the form is complete, the account is activated. Customers receive login credentials for training modules, software licensing, and technical support. These tools are integral to the Scottsdale platform. For example, when new operators begin learning how to use steel framing machines, they can immediately access tutorials, videos, and documentation tailored to their roll forming machines and desired project types.

Account setup also establishes a record for long-term tracking. This way, Scottsdale can provide consistent support, understand each customer’s goals, and ensure the roll forming machines are delivering as promised.

Phase 3

Welcome and Kickoff of the Roll Forming Journey

With the account active, the onboarding process formally begins. Customers receive a welcome package that outlines onboarding steps, key milestones, and contact details for support services.

A kickoff meeting is scheduled, often with the customer’s leadership and production teams present. During this session, the customer success manager introduces the portal, the support services, and installation files. The support services include the customer portal, the Knowledge Base platform, and the ticketing system. The team also reviews all installation files for the roll forming machines, ensuring the customer understands what to expect during roll forming machine setup.

This is more than an orientation; it’s a chance for our customers to ask questions, share concerns, and see that Scottsdale is committed to walking beside them. Customers investing in steel framing machines often have ambitious growth plans, and the kickoff meeting sets the tone for a trusted partnership.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Phase 4

Financial and Information Pack for Steel Framing Machines

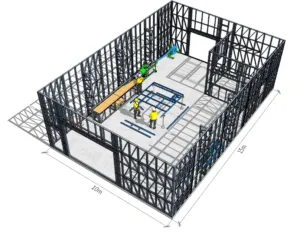

Phase 4 centers on clarity and preparation. Payment milestones are confirmed with the customer. Alongside this, the customer success manager provides a comprehensive information package. The information packages include manuals and technical specifications for the roll forming machines, shop preparation documents, wiring diagrams, electricity requirements, and floorplan layouts. They even cover operational supply checklists, ensuring our customers know exactly what steel coil, materials and tools they need when their steel framing machines arrive.

By the end of this phase, our customers have everything required to prepare their steel framing factory or jobsite for installation. They are equipped with step-by-step guidance to create an environment where their roll forming equipment performs flawlessly and the steel framing shop performs at capacity.

Phase 5

Training and Scheduling for Roll Forming Operations

Training is one of the most critical parts of our onboarding. Scottsdale believes that customer success depends on people, not just the roll forming machines and technology behind them. For this reason, we provide comprehensive training for our customer teams.

Software training comes first. Personnel learn how to use the Scottsdale software, ScotSteel, ScotStruct, and ScotRF, to design, detail, engineer, create drawings, and translate plans into production files for the steel framing machines to fabricate. Once training is completed, the customer success manager assists the team with installing the software, verifying that everything is operational. Every personnel that completes the training is presented with a certification document.

This phase often sparks excitement. Our customers begin to see how their investment in roll forming machines translates into real-world capability. They learn to design wall panels, cold-formed steel trusses, and complete steel framing systems, gaining confidence that they can deliver projects faster and more precisely.

Review a variety of Scottsdale’s steel framing projects by visiting our Sketchfab Library and explore all the possibilities of steel framing roll forming machines.

Project Highlight

From Imagination to Implementation of Steel Framing Solutions

Cold-formed steel stairs illustrate this potential perfectly. Traditional straight flights are easy to manufacture and assemble, but modern roll forming technology makes curved, spiral, or multi-directional staircases equally achievable. In this recent project, manufactured by Scottsdale’s Scotpanel 7090 roll forming machine, it showcases how elegant, sculptural stairs can be fabricated quickly and accurately. Any of Scottsdale’s Scotpanel roll-forming machine models can fabricate cold-formed steel stairs. The key lies in our design software (ScotSteel, ScotSruct, and ScotRF) and BIM integration. Architects and engineers can push creative boundaries, while detailers generate a virtual build to verify every connection before production begins, all within the Scottsdale ecosystem.

Phase 6

Delivery and Commissioning of Steel Framing Machines

After software training, the focus shifts to the roll forming process and equipment. Scottsdale coordinates delivery and shipping, making sure the roll forming machines arrive safely and on time. Installation and commissioning are handled by Scottsdale engineers, who set up the machines, calibrate them, and test their output.

Commissioning is more than flipping a switch. It involves verifying that every cut, notch, and hole produced by the steel framing machines meets specifications. Customers also complete hands-on machine training, ensuring operators understand daily maintenance, troubleshooting, and production workflows.

Certification is awarded to every team member who completes roll forming machine training successfully. This step formalizes the skills gained and gives businesses peace of mind knowing their staff are qualified to operate advanced roll forming machines.

Phase 7

Ongoing Customer Success with Roll Forming Technology

Onboarding doesn’t end with installation. Scottsdale’s commitment to customer success extends into the long term. Customers receive periodic check-ins, roll forming machine performance reviews, and updates on new resources.

Our engineering and support teams remain available to answer questions, troubleshoot issues, or suggest optimizations. For example, if a customer wants to expand into multi-profile production, Scottsdale can guide them on upgrading their steel framing machines or adding additional roll forming machines. Ongoing support helps businesses stay competitive in an evolving construction industry.

Building Long-Term Partnerships in Steel Framing

The seven-phase onboarding process ensures that every customer has a smooth, consistent, and empowering experience. It transforms the purchase of roll forming machines into a partnership built on trust, training, and long-term support.

For Scottsdale, customer success is not a slogan. It’s a strategy that ensures every investment in steel framing machines pays off. By combining world-class roll forming technology with hands-on guidance, we help our customers confidently expand their steel framing capabilities, deliver stronger projects, and grow their businesses.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Launch a Successful Steel Framing Business

- Blog – Get Private Practical Training with Every Roll Forming Purchase

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – How to Maintain Critical Components in a Roll Former Assembly

- Video – Large Steel Home Easily Carried by Workers

- Video – Why Tag Frames Trusts Scottsdale in Roll Forming Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.