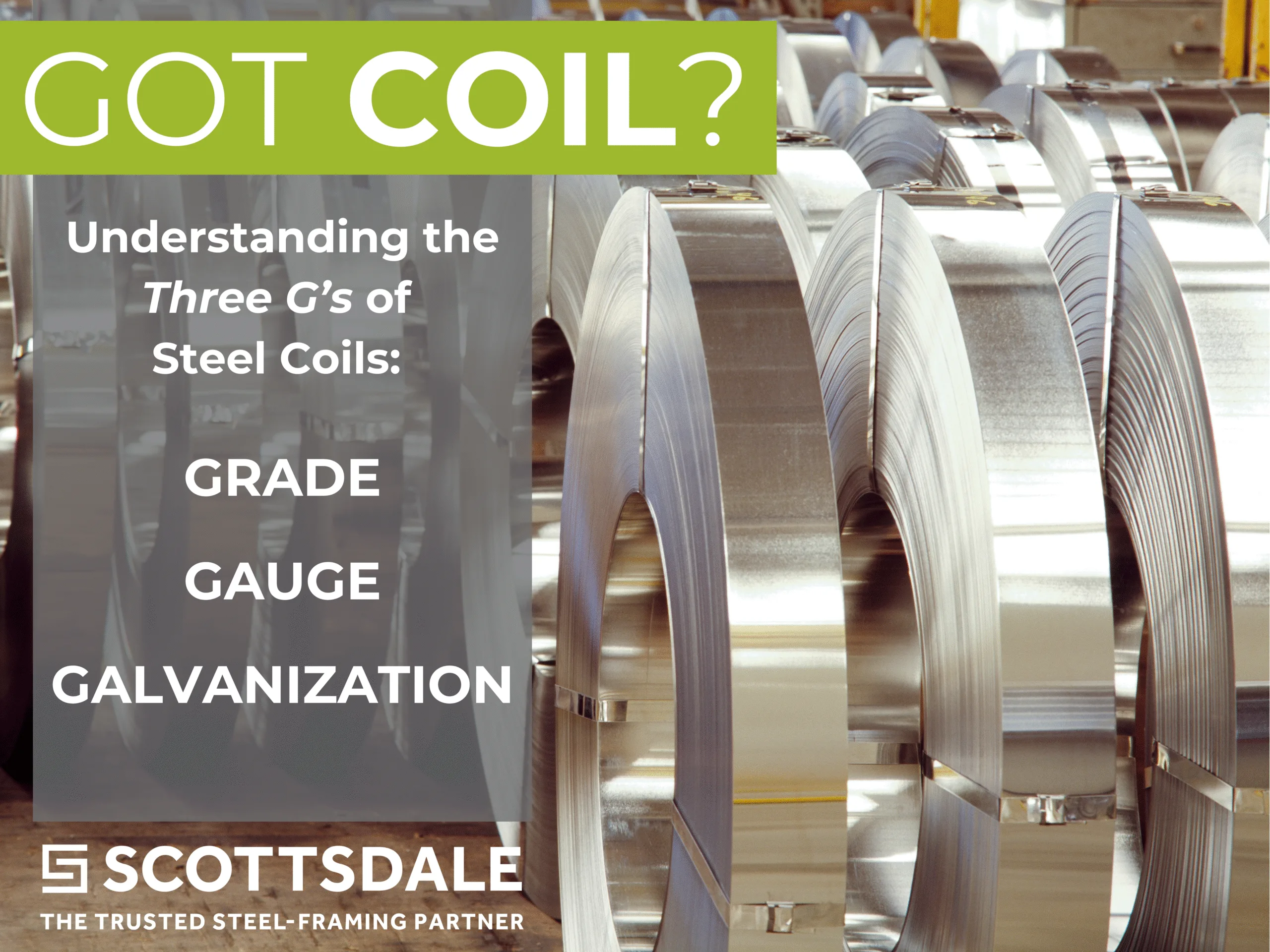

In cold-formed steel construction, ordering the right steel coil is essential for achieving the strength, consistency, and quality required for roll forming and steel framing applications. Whether you’re setting up a new production line or optimizing your supply chain, understanding the key parameters that define your raw material can make all the difference. At the core of every roll forming operation is the steel coil, an engineered raw material that feeds directly into roll forming machines to produce steel framing components such as studs, tracks, walls, joists, and trusses. To ensure optimal performance from your equipment and structures, every coil order should clearly specify the “Three G’s” of Grade, Gauge, and Galvanization.

Grade – Understanding Steel Strength

Steel grade refers to the yield strength of the material, typically specified in kilopounds per square inch (ksi). Common grades in cold-formed steel framing include:

- Grade 33 (33 ksi): Standard for interior non-load bearing applications.

- Grade 50 (50 ksi): Common for structural framing in mid-rise and high-load areas.

- Grade 65 (65 ksi): Used for heavy-duty load-bearing applications and long spans.

Choosing the correct grade depends on your structural design requirements. Higher grades allow for thinner material without sacrificing performance, improving cost and weight efficiency.

Gauge – Steel Thickness and Structural Performance

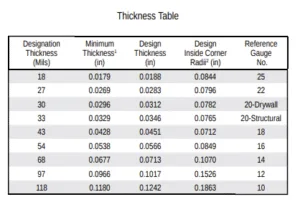

Gauge refers to the thickness of steel. It affects both the weight and structural capacity of the finished framing product. Base metal thickness and design thickness are two important terms used in the design of cold-formed steel members and are dependent on location and governing building codes and standards. Framing standards such as AISI S240 play an essential role in specifying the thickness designation for various cold-formed steel components.

It is important to understand the relationship between thickness (Mils), Gauge, Base Material Thickness (BMT), Design Thickness, and the conversion between inches and millimeters. Refer to the thickness table below from SFIA Technical Guide for more information. Learn more about the topic by referring to our detailed article “A Practical Guide To Cold-Formed Steel Thickness”.

Minimum Thickness represents 95% of the design thickness and is the minimum acceptable thickness delivered to the jobsite based on AISI S100-16.

Use your structural load calculations to determine the appropriate gauge for the cold-formed steel member. Heavier gauges (14 or 12) are often required for longer spans or heavy loads, while lighter gauges (22 or 25) are more suitable for non-load-bearing walls and interior partitions.

Galvanization – Protection Against Corrosion

Galvanized steel coils come with varying levels of zinc coating, designated by G-values:

- G40: Light coating, suitable for dry, interior environments.

- G60: Mid-level protection, often used for standard framing.

- G90: Heavy-duty protection for exterior or high-humidity areas.

The level of galvanization affects corrosion resistance and service life, especially in coastal or industrial settings. Always consider your project environment when specifying this parameter.

Verify Your Coil Order

Once your steel coil arrives, verify that the Grade, Gauge, and Galvanization match your order. Compare the mill certificates to your purchase order for consistency. The width of the steel coil should also be verified. This step is critical to ensure the performance and safety of your finished steel framing components and structure.

Scottsdale’s Steel Coil Ordering Information document summarizes the ordering specifications for the significant global codes in Australia (AS 1397), North America (ASTM A653/A653M), and Europe (EN 10346).

SFIA Technical Resources

Scottsdale Construction Systems is a proud member of the Steel Framing Industry Association (SFIA), which provides technical resources and support to member cold-formed steel framing manufacturers and users. Individual companies with roll forming machines can also become SFIA members. SFIA membership offers access to free technical guidance that can help your roll forming operations and business. Key SFIA resources include:

- SFIA Tech Bulletin – Steel Coil Procurement

This bulletin provides practical guidance on specifying and ordering steel coil for cold-formed steel framing. It explains how to correctly identify and document the Three G’s, interpret mill certificates, and communicate effectively with suppliers to avoid costly errors in coil ordering. Download SFIA Tech Bulletin: Volume 4, Number 2 – Steel Coil Procurement: Ordering Sheet Steel for Cold-Formed Framing.

- 2024 SFIA Product Tech Guide

A comprehensive reference for cold-formed steel framing products, this guide covers standard C-shaped and track sections, hat channels, bridging, bracing, and allowable design values. It helps ensure that manufacturers and designers are aligned on product specifications and performance expectations. Download 2024 SFIA Tech Guide for Cold-Formed Steel Framing Products.

- Download additional SFIA resources at steelframing.org.

Scottsdale Roll Forming Machines and Steel Framing Ecosystem

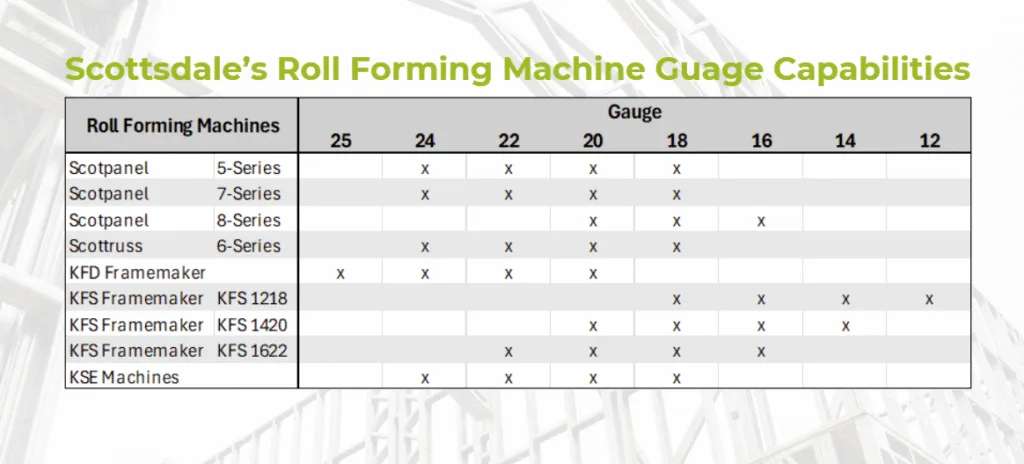

Scottsdale Construction Systems ecosystem offers a full suite of roll forming machines tailored for cold-formed steel framing. Our family of roll forming machines include:

- Scotpanel: For C-sections used in the manufacturing of walls, roofs, and ceiling systems. The 5-series and 7-series fabricate members between 24 to 18 gauges. The 8-series fabricates members between 20 to 16 gauges.

- Scottruss: For top-hat sections used in steel truss systems. The Scottruss (6-series) includes two roll forming machines. Scottruss 6050 can fabricate members between 24 to 18 gauges. Scottruss 6075 can fabricate members between 18 to 16 gauges.

- KFD Framemaker: For non-structural framing applications, includes lipped and unlipped sections. KFD Framemaker series can fabricate members between 25 to 20 gauges.

- KFS Framemaker: For structural framing applications, includes lipped and unlipped channel sections. The KFS Framemaker includes three roll forming machines. KFS 1218 can fabricate members between 18 to 12 gauges. KFS 1420 can fabricate members between 20 to 14 gauges. KFS 1622 can fabricate members between 22 to 16 gauges.

- KSE Machines: For a variety of auxiliary roll forming and specialty steel framing equipment used in walls, standing seam roof seamers, furring channels, and more. KSE machines can fabricate members between 24 to 18 gauges.

Our Scotpanel and Scottruss roll forming equipment produce sections that comply with SFIA standards and are backed by ICC evaluation reports. In addition, we provide information on the section properties of cold-formed steel members produced by KFS Framemaker, available via our SM1 document. These documents provide critical data like moment of inertia, section modulus, and torsional properties, helping engineers perform accurate structural design calculations for custom profiles.

Our Scotpanel and Scottruss roll forming equipment produce sections that comply with SFIA standards and are backed by ICC evaluation reports. In addition, we provide information on the section properties of cold-formed steel members produced by KFS Framemaker, available via our SM1 document. These documents provide critical data like moment of inertia, section modulus, and torsional properties, helping engineers perform accurate structural design calculations for custom profiles.

Global Raw Material Supplier Network

To further support our clients, Scottsdale has built a Global Component Supplier Network. This ensures access to high-quality, high-tensile galvanized steel coil from vetted global suppliers. Learn more about our supply capabilities at Scottsdale’s Operational Supply.

Ordering the correct steel coil is foundational to successful cold-formed steel framing and efficient use of roll forming machines. By focusing on the Three G’s of Grade, Gauge, and Galvanization, we ensure that steel framing components meet structural, durability, and cost-performance goals. Scottsdale provides the technical guidance, equipment, and supply chain needed to support precision-driven steel framing construction around the globe.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – The Critical Role of Coil Selection in Steel Frame Building

- Download Document – SM2 Steel Coil Ordering Information V2025.3

- Download Document – Scottsdale Construction Systems Steel Coil Specification Chart

- Video – 6,500 lbs Powered Decoiler in Operation with KFS Framemaker 1420G1

- Video – Commissioning & Training Process for Knudson by Scottsdale Roll Former KFS Framemaker 1622G1

To learn more about our roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.