Comprehensive Guide to Cold-Formed Floor Framing Systems: Key Differences Explained

Scottsdale provides both cold-formed steel floor trusses and floor joists within our product lineup through the Scottsdale and Knudson by Scottsdale roll formers. The Scottsdale roll formers are capable of producing in-line trusses using Top Hat and C-section profiles, which are designed to offer high strength and stability for various construction applications. Cold-formed steel (CFS) profiles are revolutionizing the construction industry with their impressive strength-to-weight ratio. These profiles are particularly useful in creating lightweight yet robust structural components for steel frames and CFS joists that can support significant loads.

Unlike traditional wood framing, CFS c-shape joist systems offer superior performance. Steel’s remarkable strength-to-weight ratio allows architects and builders to achieve similar spans and loads with wider joist spacing, leading to efficient use of materials.

This efficiency not only enhances the structural integrity but also reduces the overall cost of labor and materials. By choosing steel, construction projects can optimize their designs, making them both economical and reliable. On the other hand, the Knudson series of roll formers can manufacture floor trusses both in-line (minor axis) and strongback (major axis). The in-line trusses are typically used for applications where the load is distributed along the minor axis, providing efficient load-bearing capabilities. Strongback trusses, produced along the major axis, offer enhanced rigidity and support for larger spans and heavier loads. Below are typical sectional views of the various floor trusses and joist types that can be produced through our roll formers, showcasing the versatility and adaptability of our cold-formed steel floor framing system to meet diverse residential and commercial construction needs.

Steel’s sustainability in construction is significantly enhanced by its exceptional recyclability. Unlike many materials, steel can be recycled endlessly without losing its inherent properties. This unique feature ensures that steel maintains its strength and durability, even after being reused multiple times.

Moreover, the recycling process for steel is not just efficient but also environmentally friendly. When steel is melted down and reformed, it avoids the depletion of natural resources and reduces the need for new raw materials. This leads to a remarkable reduction in energy consumption and greenhouse gas emissions.

Additionally, steel never becomes a lesser product through recycling, a process known as downcycling. This means that recycled steel is just as robust and dependable as newly manufactured steel, making it a consistent and reliable choice in construction.

Overall, the recyclability of steel plays a pivotal role in promoting sustainable building practices, reinforcing its reputation as an eco-friendly material.

Further information on the section dimensions and the capabilities of different roll formers is available in the attached article from our archives.

Click here to know more about Scottsdale’s ecosystem.

Cold-Formed Steel Floor Framing System: Practical Example with Strength and Cost Comparison

Different floor framing system offers different strengths based on the configuration, choice of CFS section, steel thickness, and grade. Cold-formed steel lattice floor trusses and joists are considered for comparison. Images of floor trusses and joists are shown below

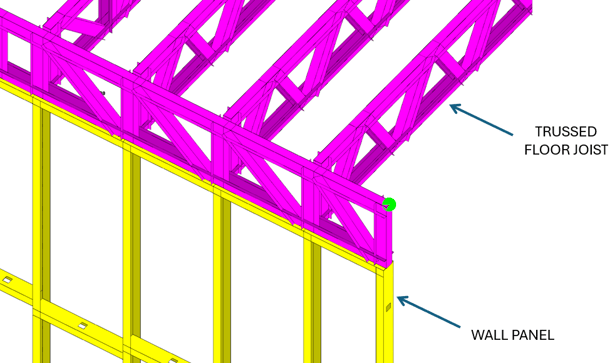

Picture showing cold-formed steel lattice floor trusses

Picture showing cold-formed steel lattice floor trusses

Picture showing cold-formed steel floor joist – Image courtesy US Frame Factory

A typical residential floor span of 6 m [~20 ft] between load-bearing walls is considered for this study. The loads considered for the example include the following

- Dead load = 0.9 kPa

- Live load = 1.5 kPa

- Point load = 1.8 kN

Cost Implications of Using CFS Joists Compared to Wood

In recent years, the construction industry has witnessed a notable shift towards cold-formed steel joists, largely due to the fluctuating and often increasing costs of wood. This trend is primarily driven by the affordability and resilience of CFS when juxtaposed with traditional wood options.

The Cost of Wood

Wood prices have been on an upward trajectory, reaching new heights due to a combination of market pressures. For instance, as of September, lumber prices surged to $641.60 per thousand board feet, marking a significant increase attributed to factors like limited supply and increased demand. Events such as tariffs and natural disasters like forest fires have historically contributed to these spikes.

Advantages of Cold-Formed Steel

In contrast, CFS joists offer a stable pricing structure. The production process of steel allows for more predictable pricing, unburdened by the environmental and market volatility that plagues the lumber industry. Moreover, CFS is known for its durability, reducing long-term maintenance costs and offering a compelling argument for its adoption in modern construction.

Long-term Savings

While the initial costs of CFS joists might present a comparable investment to wood, the longevity and reduced need for replacement due to their robust nature provide significant economic benefits over time.

By selecting CFS joists, builders and architects not only counteract the unpredictable nature of timber costs but also invest in a material that promises strength and consistency, making it a financially savvy choice for the future of construction projects.

Comparing CFS Joists to Wood Joists: Warping, Bowing, Splitting, and Structural Integrity

When evaluating the advantages of CFS joists over traditional wood joists, several factors come into play that highlight CFS’s superiority.

Warping and Bowing:

One of the most notable differences is that CFS joists are immune to warping and bowing, a common issue with wood joists. Wood, being an organic material, is prone to dimensional changes with fluctuations in moisture and temperature. This instability can lead to structural problems over time.

Splitting and Integrity:

Wood joists can splinter or develop knots, which not only affect their structural performance but can also make installation challenging. CFS joists, however, offer a seamless solution. Their uniform composition means they don’t split, ensuring a consistent and reliable installation process.

Dimensional Stability:

CFS joists provide outstanding dimensional stability. Unlike wood, they do not shrink over time, which helps prevent issues such as nail popping and wall cracking. This stability contributes to a cleaner, more durable finish in construction projects.

In summary, for builders seeking reliability and long-term structural integrity, CFS joists stand out as a superior choice compared to wood joists, offering a myriad of benefits that ensure performance without compromise.

Scottruss Cold-Formed Steel Hat Section Lattice Floor Truss: Key Features and Benefits

A 6050 [2 inch] Scottruss Hat section made from 0.95 mm [20 Ga] thick G550 [80 ksi] grade steel is required to pass structural adequacy for the given loads. This translates to 19.8 linear meters of steel per truss, with each joist weighing 25.5 kg. Additionally, assembling a single floor truss necessitates 44 bolts and nuts. Typical floor trusses to wall connections are shown in the image below.

Knudson by Scottsdale KFS Framemaker: Cold-Formed Steel Floor Joists Explained

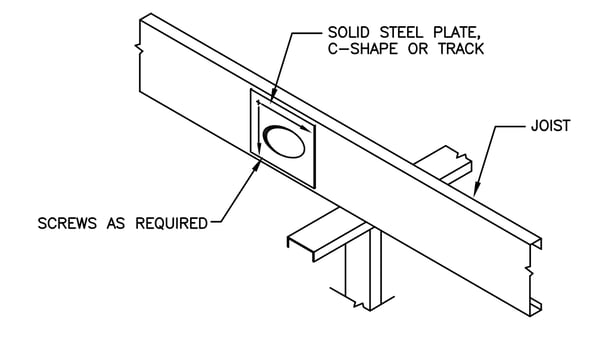

Conversely, a C-section cold-formed steel linear floor joist 1200S350-54 (SFIA / SSMA section) by using the KFS 1218 Framemaker, using G350 grade steel, can also meet the structural adequacy for the specified loads. This will weigh 35.36 kg for the 6m span. However, no additional fasteners are needed to assemble the webs, as in the case of a trussed floor joist, making the manufacturing process a lot faster. A typical floor joist sitting on a cold-formed steel wall stud is shown below.

Follow the Steel Framing Industry Association (SFIA) technical manual for more details on a typical floor joist to wall stud connection.

Enhancing CFS Joists Integration with Service Punchouts and Features

Cold-formed steel joists are evolving beyond traditional designs, with innovative features that significantly enhance their integration into building systems.

Advanced Service Punchouts:

One key improvement lies in the creation of service punchouts. These punchouts, equipped with reinforcement lips, allow for easy routing of utilities such as electrical, plumbing, and HVAC without compromising structural integrity. This means more efficient construction processes, as it reduces the need for additional drilling or cutting on-site.

Innovative Bending and Folding:

CFS manufacturers have also introduced innovative bends and folds in joist designs. These enhancements provide greater flexibility and adaptability in a variety of construction scenarios, whether it’s curtain walls, load-bearing frames, or steel beam integrations. Such adaptability supports faster assembly and a smoother alignment with other materials, facilitating a range of architectural styles.

Comprehensive Support Accessories:

Moreover, joists now come with a suite of support accessories like rim tracks and bracing. These components ensure robust connections in complex building systems. They work seamlessly with concrete masonry units, steel frames, and even panelized construction methods. This creates a cohesive framework that simplifies the building process and enhances overall structural stability.

With these features, CFS joists not only fit neatly into diverse construction methodologies but also improve the efficiency and reliability of building system integrations.

Architects and builders might prefer wider joist spacing with cold-formed steel for several compelling reasons. First and foremost, CFS has an exceptional strength-to-weight ratio, making it the most efficient material for construction. This allows for the use of fewer joists without compromising structural integrity, ultimately reducing both labor and material costs.

By opting for wider spacing, architects can also streamline the design process, leading to faster project completion and improved efficiency on the construction site. Additionally, CFS provides enhanced flexibility in design, enabling longer spans that are challenging to achieve with traditional wood framing.

This flexibility allows builders to create more open and adaptable spaces, which are increasingly in demand in modern architecture. Furthermore, with its resistance to elements like rot and pests, CFS adds longevity to structures, offering long-term benefits alongside initial cost savings.

Cold-Formed Steel Floor Trusses vs. Floor Joists: A Cost Analysis Summary

Using the internal cost comparison tool, developed from decades of experience in the metal framing industry, a truss joist produced with the Scottruss Hat section machine costs approximately $4.5 USD per linear meter, while C-section joists cost $5.5 USD. At first glance, it may appear that C-section joists are more expensive to manufacture than trussed joists. However, several factors should be considered when selecting the appropriate flooring system for your project.

- The cost comparison does not account for the labor efficiency in assembling the joists. Slower assembly speeds can significantly increase the cost of trussed joists. In contrast, this factor does not impact the cost of C-section joists, as they require little to no labor for assembly and can be directly rolled out of the roll formers.

- C-section joist profiles are thicker than trussed joists, with 1.5 mm steel used for C-section joists compared to 1.15 mm steel for trussed joists. The 26% difference in thickness results in a higher weight and slightly increased cost for the joists. However, the greater thickness also enhances the strength of the floor joists, allowing for longer spans compared to trussed joists.

- Another crucial aspect to consider is the speed of rolling the profile. The KFS Framemaker excels in this area, as it involves fewer operations to produce the section compared to the Scottruss roll former. The production speed of trussed floor joists also heavily depends on the efficiency of the assembly crews.

Therefore, all these points must be carefully evaluated when choosing the right flooring system for your project.

Refer to the white paper to know more about the practical comparison between Hat section and C-section trusses.

Contact us to learn more about the various cold-formed steel floor systems we offer to help you achieve significant savings on your next project.

What Makes CFS a Resilient Choice for Construction in Storm-Prone Areas?

Cold-Formed Steel has become a top choice for construction in regions frequently hit by tropical storms and hurricanes. Its resilience is rooted in several key attributes:

Superior Strength and Durability

CFS is renowned for its impressive strength-to-weight ratio, which ensures structures can withstand severe weather conditions. Unlike other materials, CFS does not warp, rot, or succumb to termites, making it a long-lasting option for both single-story and multistory buildings.

Flexibility and Adaptability

The flexibility of CFS allows for a wide range of architectural designs, catering to both aesthetic and functional needs. This adaptability ensures that structures can be built to specific requirements, maximizing safety and stability even in the most challenging of environments.

Intrinsic Benefits of Cold-Formed Steel

- Non-Combustible: CFS is non-combustible, providing an added layer of safety during fire-related incidents.

- Sustainable: Made from recycled materials, CFS is an environmentally friendly choice that supports sustainable building practices.

In a world where climate conditions are becoming increasingly unpredictable, choosing CFS offers peace of mind to homeowners, architects, and builders aiming for robust and enduring structures in disaster-prone regions.

How the Rising Price of Lumber Has Boosted Cold-Formed Steel Demand

The construction landscape is shifting as the cost of lumber climbs, shining a spotlight on Cold-Formed Steel as a favored building material. The increasing expense of wood is steering owners, architects, and builders toward CFS, thanks to its impressive resilience and cost-effectiveness.

Key Influencers in Material Selection

- Lumber Prices on the Rise: Recently, we’ve witnessed a significant increase in the cost of lumber. For instance, by September, prices hit a record $641.60 per thousand board feet, as highlighted by the Wall Street Journal. This surge has pushed industry professionals to explore alternative materials.

- CFS Advantages:

- Structural Integrity: CFS offers unparalleled strength, comparable to traditional timber methods, making it a compelling choice.

- Competitive Pricing: Despite fluctuations in material costs, CFS remains an attractive option due to its stable pricing.

Builder and Architect Considerations

With the lumber market’s volatility, the reliability and affordability of CFS make it a strategic investment for projects aiming to balance cost and performance. This trend underscores a broader shift in the industry, as sustainable and economical choices gain momentum.