In cold-formed steel construction, efficiency isn’t just about strength, but it’s also about smart detailing. Using less steel doesn’t mean cutting corners; it means understanding how loads travel, how steel framing members interact, and how to get the most out of your roll forming machines. Whether you’re producing cold-formed steel wall panels and trusses in a factory or onsite, these detailing tips will help you save cold-formed steel material, lower costs, and keep your structures strong.

Tip #1

Thicker Members Don’t Always Result in Heavier Structures

With advanced roll forming machines, fabricators can easily produce different section thicknesses. In many cases, a single thicker stud or truss member can replace several thinner members, reducing the overall weight of the cold-formed steel framing while speeding up fabrication and installation. Smart steel framing design means focusing on overall efficiency, not just quantity.

Tip #2

Understanding the Load Paths is Essential to Steel Framing Design

Steel framing detailing requires more than precision in fabrication; it requires precise design. Scottsdale roll forming machines deliver exact dimensions, but even perfectly formed studs can waste steel if the load path isn’t optimized. Steel is strongest in compression, and aligning studs and trusses vertically ensures loads travel directly from member to member and into the foundation. Misaligned members may lead to more steel in the design and weaker performance of members.

Tip #3

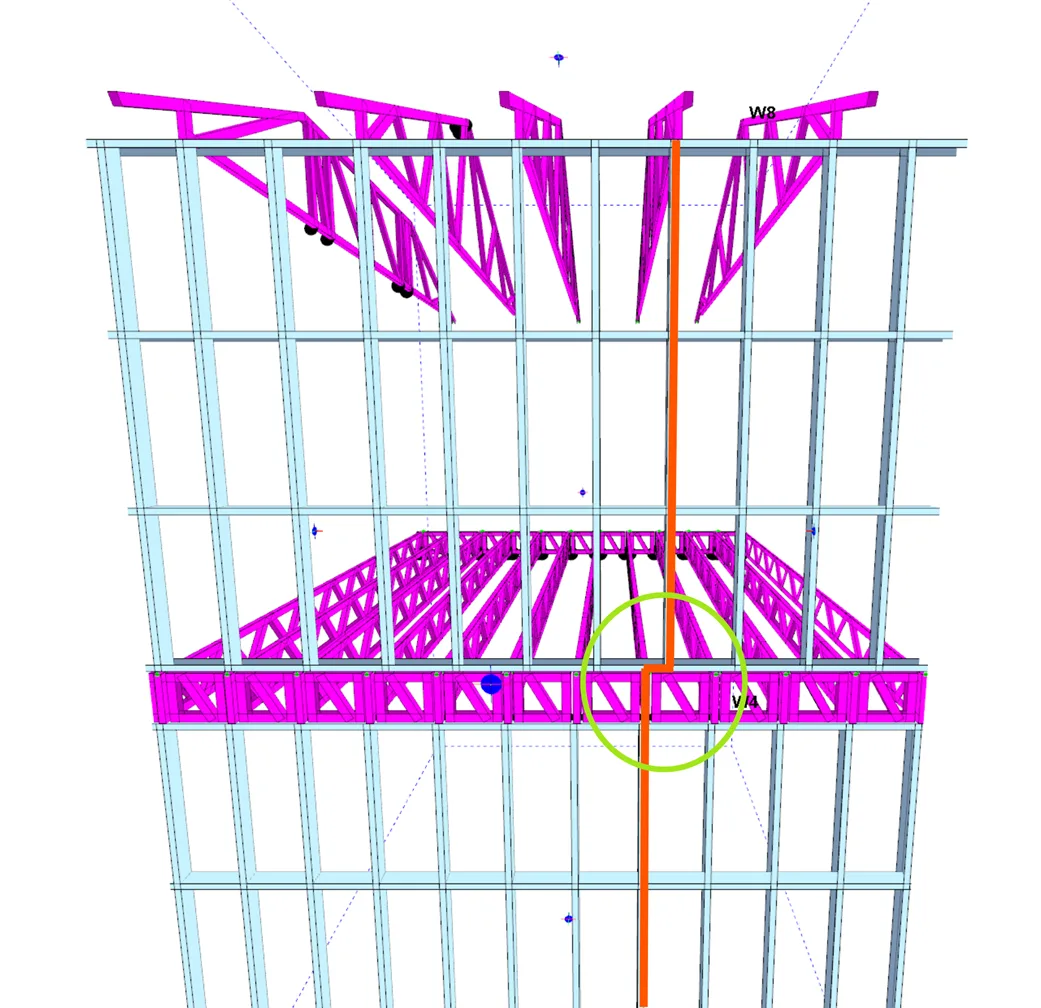

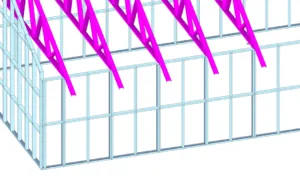

Optimizing Truss Placement and Wall Panels in Steel Framing

When producing cold-formed steel trusses with Scottsdale roll forming machines, align trusses directly above vertical studs in wall panels. This allows one vertical member in the wall to support both truss loads and exterior sheathing, eliminating redundant framing members. This approach enhances steel framing design while cutting unnecessary steel usage, resulting in material cost savings and an overall lighter structure.

Tip #4

Sharing Vertical Cold-Formed Steel Support Members

Not every cold-formed steel truss requires a dedicated vertical member. With efficient cold-formed steel framing design, ply trusses can share back-to-back (B/B) members. This ensures every vertical member works to full capacity without overbuilding. Strategically placing trusses over shared members reduces the number of studs required and simplifies overall steel framing detailing.

Tip #5

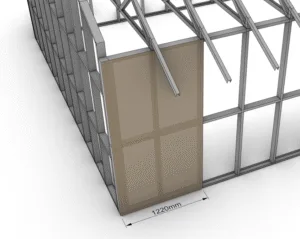

Strategically Segmenting Cold-Formed Steel Wall Panels

When segmenting wall panels in Scottsdale’s software ecosystem, cold-formed steel wall panels should be cut where studs already exist. This prevents additional studs from being added solely for segmentation, ensuring that steel framing detailing stays efficient and economical.

Tip #6

Choosing the Right Bracing for Lateral Force Resisting Systems in Steel Framing

Lateral force-resisting systems are essential in cold-formed steel framing design. Knowing when to use X-bracing (strap bracing) or K-bracing is key. X-bracing provides superior lateral support and usually requires less steel compared to K-bracing. For both structural safety and material savings, X-bracing is often the best choice for steel framing design.

In a recent research study, Scottsdale’s test and analysis revealed that 150mm X-bracing delivers a capacity of 15kN, far outperforming traditional methods such as K-bracing, which provides only 1kN capacity. In addition to its superior strength, X-bracing is significantly more cost-effective, as it can be fabricated using offcuts from the mother coil. Bracing plays a critical role in the structural integrity of light-gauge cold-formed steel buildings, where builders often rely on a mix of X-bracing, K-bracing, and bracing boards to meet design and performance requirements.

Learn more about this topic by reading our blog “All You Need to Know on Strap Bracing vs. K-Bracing”.

Tip #7

Eliminating Non-Load-Bearing Headers in Steel Framing

In non-load-bearing walls, such as those around interior doors and openings, headers are often unnecessary. By eliminating non-load-bearing headers, builders can reduce cold-formed steel usage, make wall panels lighter, and maintain structural integrity. This simple detailing change can result in significant material savings in steel framing design.

Scottsdale Construction Systems has a large library of cold-formed steel detailing documents and roll forming documents available on our KnowledgeBase platform.

For more cold-formed steel design and steel framing detailing insights, visit us at https://knowledge.scottsdalesteelframes.com/.

Building with Scottsdale Roll Forming Machines

Scottsdale roll forming machines offer complete flexibility for builders and manufacturers working with cold-formed steel framing. From wall panels and floor joist systems to roof trusses and full modular structures, these roll forming machines deliver precision and versatility for every application. By enabling fabricators to produce both load-bearing and non-load-bearing systems, Scottsdale roll forming technology supports the fabrication of the entire building envelope.

Watch a short video showcasing how simple cold-formed steel wall design, engineering, fabrication, and erection can be with Scottsdale’s advanced roll forming technology.

With Scottsdale roll forming machines, builders can confidently manufacture cold-formed steel walls, steel trusses, and complete steel framed buildings, whether working on residential, commercial, or industrial projects. The ability to fabricate high-quality cold-formed steel framing components ensures efficiency in production, accuracy in steel framing design, and durability in finished structures.

Smarter Steel Framing Design with Scottsdale Roll Forming Technology

Steel framing design is about more than strength; it’s about efficiency, detailing, and smart design engineering choices. By optimizing load paths, reducing redundant members, and making strategic bracing decisions, builders can use less cold-formed steel material without compromising structural performance.

Scottsdale’s roll forming ecosystem makes it possible to apply these techniques with precision and confidence. Whether you’re manufacturing wall panels, trusses, or complete building envelopes, smart steel framing detailing paired with the right software solutions – ScotSteel, ScotStruct, and ScotRF – and advanced roll forming technology, ensures stronger, lighter, and more cost-effective cold-formed steel framing solutions.

Learn how Scottsdale’s roll forming technology and software support business growth by watching our video below.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Design Cold-Formed Steel Double Top Chord Lintels

- Blog – Practical Guide to Web Openings in Cold-Formed Steel Framing

- Blog – New Solution for Fascia Bracket Installation in Cold-Formed Steel

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Blog – A More Simplified Way of Designing Cold-Formed Steel Framing

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.