At Scottsdale Construction Systems, we’re constantly working to enhance how fabricators, builders, and engineers interact with cold-formed steel (CFS) to improve their steel framing operations and workflow. We have partnered with GRAITEC StrucSoft to integrate MWF directly into Scottsdale’s software workflow, giving our users the best of both worlds: the visual design capabilities of Revit plus the precision manufacturing environment of Scottsdale’s roll forming ecosystem.

Streamlining Cold-Formed Steel Design in Revit: What is MWF?

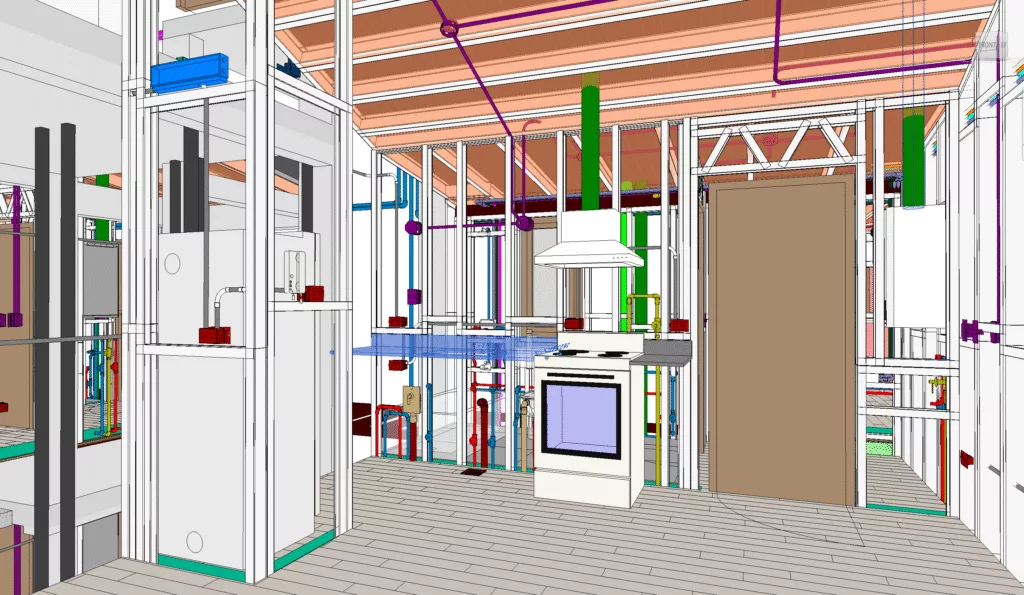

MWF stands for “Metal Wood Framing”, a powerful plug-in developed by StrucSoft Solutions for Autodesk Revit. It’s specifically built to streamline the modeling, detailing, and documentation of light-gauge steel (LGS) and wood framing within a BIM environment.

MWF transforms Revit files from a general modeling tool into a framing-specific design platform. It automates tasks that would otherwise be time-consuming and error-prone, such as:

- Placing studs, tracks, bracing, and openings,

- Detecting clashes with MEP systems or structural components like concrete beams and posts,

- And generating framing layouts, construction details, and material takeoffs.

Any panel or truss designed in Revit with MWF can be exported as an SCS file, the native file format for Scottsdale’s ScotSteel software. From there, our users can:

- Import models directly into ScotSteel and run structural analysis,

- Conduct clash detection and coalition tests before fabrication,

- Produce precision-ready files for ScotRF roll forming software,

- And minimize manual adjustments and prevent errors on the shop floor.

Seamless Roll Forming Software Integration with Scottsdale’s Ecosystem

Seamless Roll Forming Software Integration with Scottsdale’s Ecosystem

Scottsdale is a leading roll forming manufacturer with state-of-the-art software that supports users from design of cold-formed steel members all the way through production all on a single platform. We are closing the gap between BIM design and automated roll forming without forcing users to switch platforms mid-process.

Scotpanel and Scottruss Roll Forming Machine Workflow

The workflow and the corresponding decision tree relative to the usage of Revit or operating entirely in ScotSteel depends on the type of the Scottsdale roll forming system deployed. First, we will explore Scotpanel and Scottruss. Scottsdale’s core software suite, ScotSteel, ScotStruct, and ScotRF, are known for enabling accurate design-to-manufacture workflows for cold-formed steel structures. ScotSteel operates as a fully standalone design environment. However, for users who prefer to maintain Revit within their workflow, seamless integration with Revit is available for added convenience. With MWF integration, users who prefer working in Revit can now stay in their native BIM environment while still producing data-rich outputs ready for fabrication.

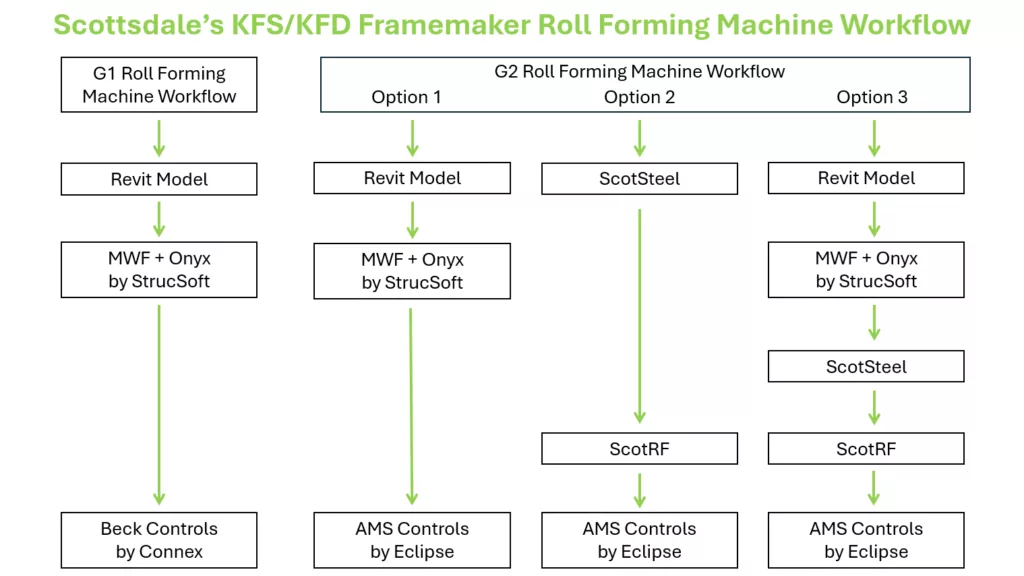

KFS and KFD Framemaker Roll Forming Machine Workflow

Next, we explore software workflows when operating with our KFS and KFD Framemaker families. There are multiple design pathways available, determined primarily by two factors: 1. the specific roll forming machine in use, and 2. the user’s preferred design software. For the KFS and KFD Framemaker series, design workflows differ based on whether you’re operating a G1 or G2 generation of the roll forming machines. The corresponding workflows can be summarized as follows:

G1 Roll Forming Machines Workflow:

Our G1 KFS/KFD Framemaker roll formers provide a basic, yet complete design/CNC production work path aimed at users who primarily prefer to start work in Revit environment.

- Begin with a Revit model.

- Use the MWF converter in combination with Onyx by StrucSoft to generate machine-ready framing files.

- Files are fed directly into Beck controls, which operate through Connex CNC software to run the roll forming production.

G2 Roll Forming Machines Workflows:

Our G2 KFS/KFD Framemaker roll forming machines give the users flexibility and freedom to design, operate, and produce cold-formed steel framing members in their chosen environment.

Option 1: It is a design path workflow similar to that presented for G1 KFS/KFD roll formers.

- Begin with a Revit model.

- Use the MWF converter in combination with Onyx by StrucSoft to generate machine-ready framing files.

- Transfer files into AMS controls via Eclipse for roll forming production.

Option 2: This is the simplest design path available.

- Design directly in ScotSteel environment.

- Export files to ScotRF for production.

- Transfer files into AMS controls via Eclipse for roll forming production.

Option 3: This is a similar workflow path to option 2, except with the insertion of Revit.

- Begin with a Revit model.

- Use the MWF converter in combination with Onyx by StrucSoft to generate machine-ready framing files.

- Import files into ScotSteel and manipulate the files further as needed.

- Export files to ScotRF for production.

- Transfer files into AMS controls via Eclipse for roll forming production.

Scottsdale’s KFS/KFD Framemaker roll forming machine workflow options outlined above are conveniently summarized in the flowchart below.

Why Does Software Integration in Roll Forming and Design Matter?

In an era where Building Information Modeling (BIM) is central to construction success, using tools that align digital models with real-world manufacturing is a game-changer. Integrating MWF into your Scottsdale workflow allows for:

- Early conflict resolution with full MEP model visibility,

- Accurate bill of materials and engineering reports,

- Reduced errors, rework, and material waste,

- And faster project delivery and lower costs.

Whether you’re an experienced steel frame fabricator or exploring digital workflows for the first time, the partnership between StrucSoft and Scottsdale enables a highly optimized, BIM-driven steel framing process.

At Scottsdale Construction Systems, our mission is to empower the steel framing industry with best-in-class tools for design, manufacturing, and automation. MWF integration is another step forward in our journey, enabling smarter collaboration, faster project cycles, and a more connected construction process.

At Scottsdale Construction Systems, our mission is to empower the steel framing industry with best-in-class tools for design, manufacturing, and automation. MWF integration is another step forward in our journey, enabling smarter collaboration, faster project cycles, and a more connected construction process.

For any additional information or questions on this topic, reach out to us at sales@scottsdalesteelframes.com, or call +1 (888) 406-2080 (Option 1) or +61 1300 671 345. Our team of experts is ready to answer your cold-formed steel, steel framing, and roll forming questions.