In modern cold-formed steel construction, achieving high structural performance while maintaining fast and accurate installation is essential, especially in roof truss systems. A common but often overlooked challenge arises when attaching fascia brackets to cold-formed steel hat sections, a key element in steel trusses used across residential, commercial, and industrial projects. Traditional solutions have involved awkward workarounds, resulting in weak or inconsistent connections. However, advances in roll forming technology and intelligent detailing through software have made it possible to eliminate this problem before cold-formed steel members even reach the job site.

Defining The Problem

Attaching Fascia Brackets to Cold-Formed Steel Hat Sections

In steel framing, attaching a flat fascia bracket to a lipped cold-formed steel hat section, particularly over bolted connections, has long been a field challenge. The lips of the profile and the bolt heads protrude beyond the web, preventing any flat bracket from sitting flush. This issue complicates installation and compromises connection strength.

Traditional Solution

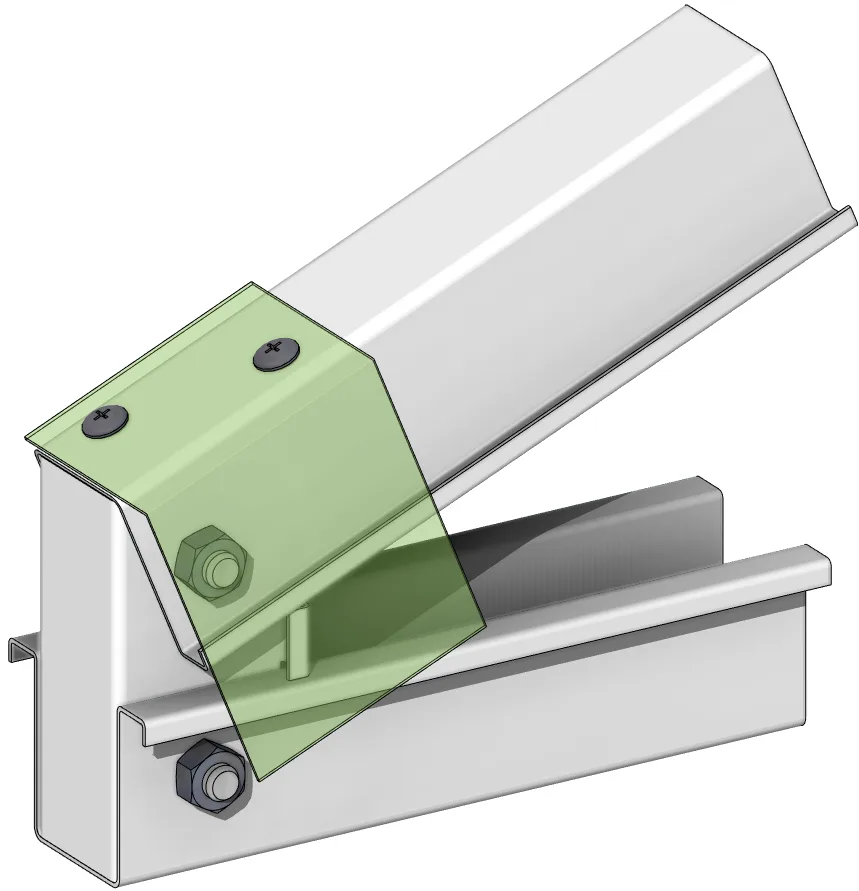

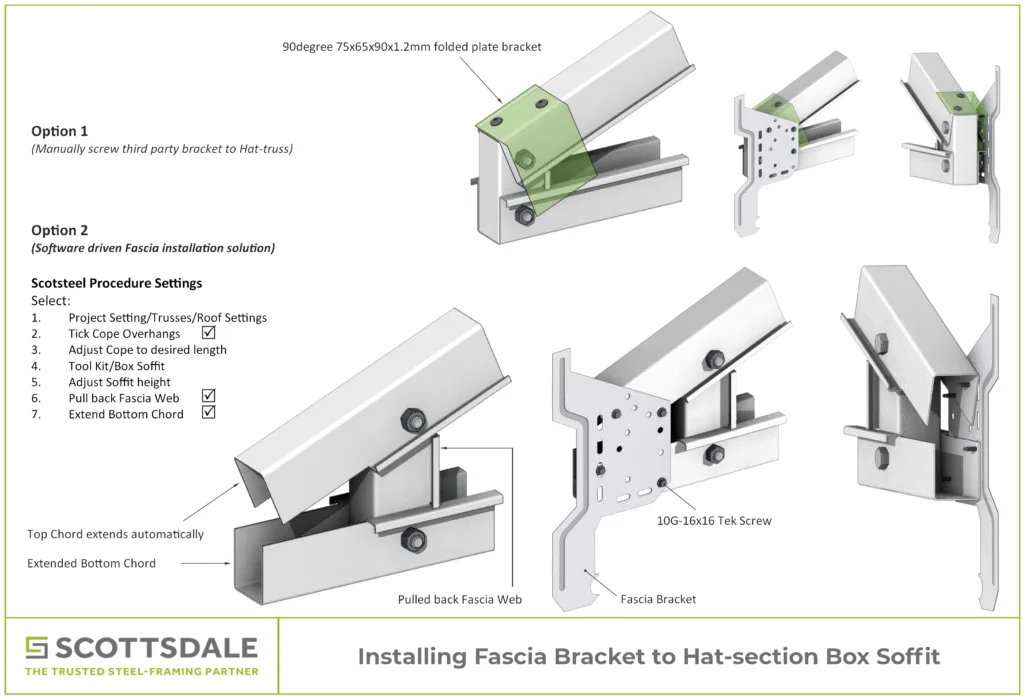

Inserting a 90-Degree Folded Bracket

The traditional solution involves inserting a 90-degree folded bracket and screwing it to the top flange of the cold-formed steel hat section profile. While this provides a flat surface for the fascia bracket, it’s an inherently weak solution. The bracket is only supported at the top flange, leaving the rest hanging unsupported, making it vulnerable to movement, stress, and deformation over time.

Modern Solution

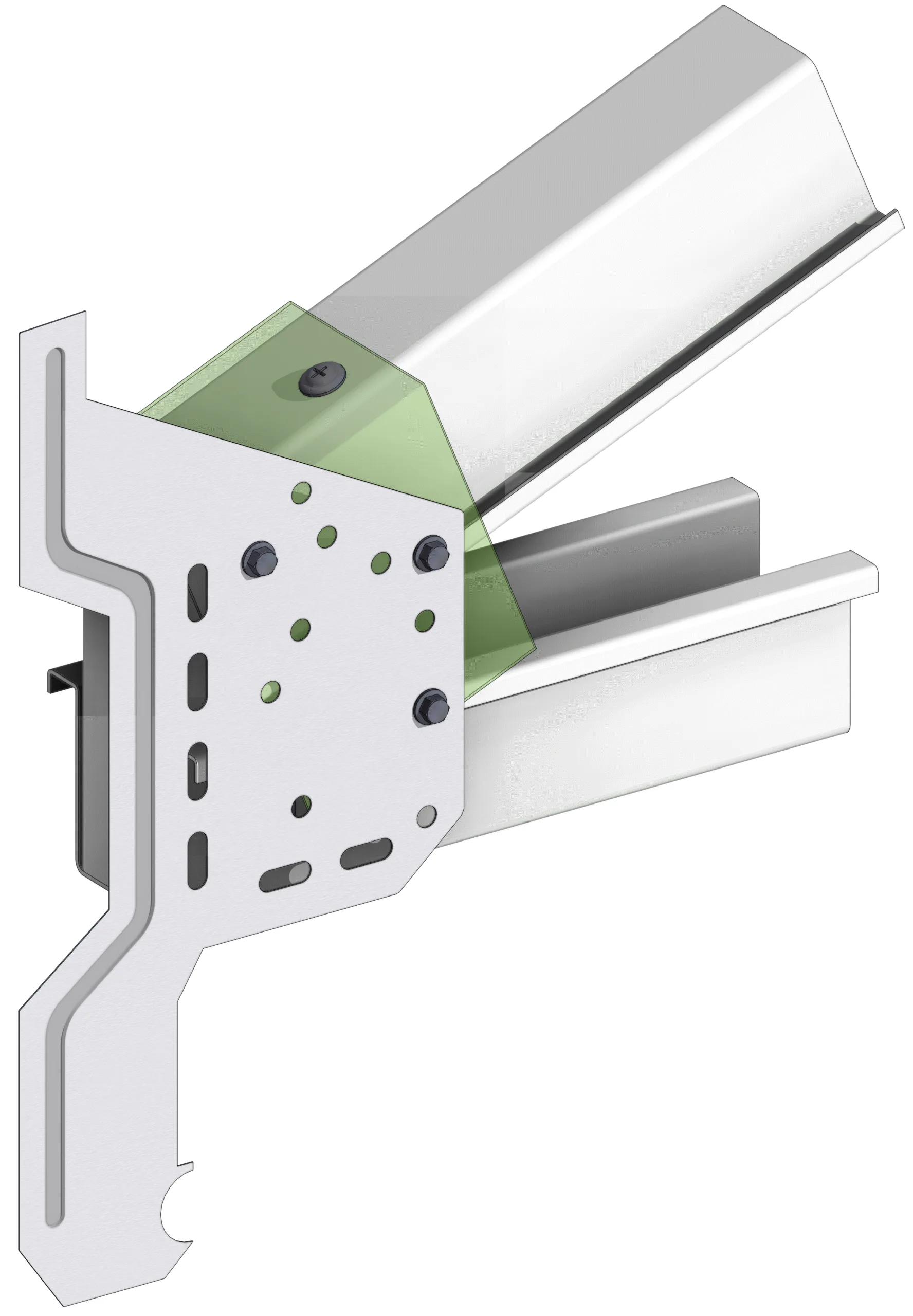

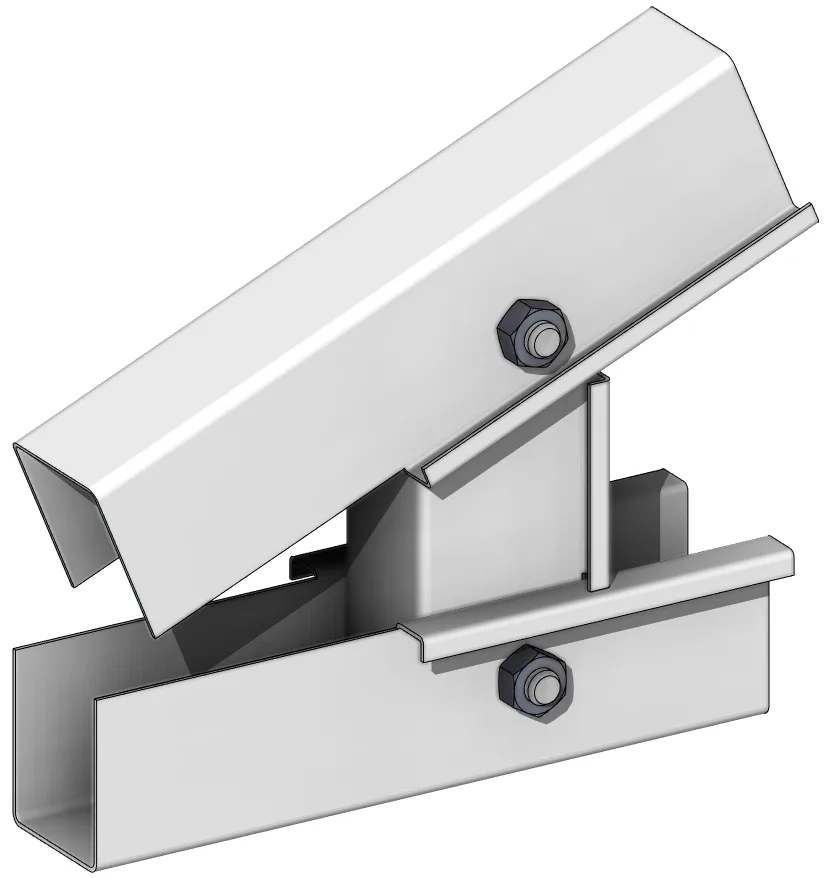

Pulled-Back Coped Truss Chords

Thanks to BIM-integrated roll forming and intelligent detailing in ScotSteel design software, Scottsdale has removed the problem altogether by removing the obstruction. Instead of covering the lips and bolts with a flat bracket, the solution is to extend the top and bottom chords and position the fascia bracket behind the lips and bolts. The bolt connection at the heel/web is therefore moved further back, and the lips of the hat section are coped (cut away), creating a clean, flush plane for the fascia bracket to sit on.

This approach eliminates the need for manual cutting or costly third-party brackets and allows the bracket to be screwed directly into both the top and bottom chords. The result is a stronger, fully supported connection within the cold-formed steel truss design.

Advantages of Scottsdale’s Cold-Formed Steel Trusses

Scottsdale delivers advanced roll forming machines designed to fabricate high-performance cold-formed steel trusses using both Hat and C-section profiles. Our Scotpanel series can produce trusses with cold-formed steel C-sections, while the Scottruss series produce trusses using cold-formed steel Hat sections.

Trusses fabricated with Hat sections offer a distinct structural advantage due to their profile shape. Unlike traditional C-sections, which have two flanges and a single web in the weaker minor axis, the Hat section features one flange and two webs in the major axis, providing superior strength and stiffness.

While some competitors use C-section profiles with inward-facing lips to simplify fascia bracket installation, this often comes at the cost of structural integrity. Scottsdale’s pulled-back coped truss chords solve both challenges, enabling fascia brackets to be mounted flush and be fastened directly to both the top and bottom chords, resulting in a stronger, more reliable connection that performs over time.

How to Design the Pulled-Back Coped Truss Chords in ScotSteel

ScotSteel gives users direct control over the fascia bracket solution during the cold-formed steel truss design process. Here is a step-by-step guide on how to configure in ScotSteel:

- Project Settings → Trusses → Roof Settings

- Select “Cope Overhangs”

- Adjust cope to the desired length

- Tool Kit → Box Soffit

- Set the soffit height

- Select “Pull Back Fascia Web”

- Enable “Extend Bottom Chord”

This method is ideal when the top and bottom chords are close enough to support direct bracket installation. However, users still have the option to revert to the traditional 90-degree bracket method if the soffit geometry makes that more appropriate.

Refer to AISI S240-20 North American Standard for Cold-Formed Steel Structural Framing, Section E, for detailed guidance on the design of cold-formed steel trusses.

Benefits of the Pulled-Back Coped Truss Chords Solution

By integrating this process into the cold-formed steel truss design, Scottsdale has eliminated the need for custom metal brackets, unnecessary labor, and inefficient field fixes. The ScotSteel software handles everything up front, during detailing and roll forming, so crews no longer need to adjust anything manually on-site.

Pulled-back coped truss chords result in better connections, faster installation, and no extra expenses for brackets.

This advancement not only saves time and money but also ensures a more structurally sound connection. Roll forming the solution directly into the steel truss eliminates the need for bracket-by-bracket installation, speeding up production while improving consistency and performance.

Scottsdale’s Complete Roll Forming Solutions

Scottsdale offers a fully integrated solution for cold-formed steel construction, combining BIM-integrated software, high-performance roll forming machines, expert training, ongoing support, and reliable steel material supply. In addition, Scottsdale provides tailored business and financial solutions to support your operations at every stage. This comprehensive approach empowers customers to innovate and resolve real-world challenges, such as the fascia bracket installation problem, efficiently and without compromising structural integrity or incurring unnecessary costs. To learn more about our roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.