The Rye Parkside redevelopment in Peckham, London, is a clear demonstration of how light-gauge steel framing and roll forming technology can deliver superior outcomes for residential developers. Rebuilt as a modern steel-framed housing complex, the project replaces a failed timber structure with a durable, precisely engineered steel-framed development designed for speed, quality, and long-term value.

From concept through construction, the use of light-gauge steel framing manufactured by a Scotpanel 5090 roll forming machine from Scottsdale Construction Systems provided the certainty and performance required for a complex, multi-building urban site. The result is a development that meets today’s expectations for safety, efficiency, and asset longevity.

London’s Rye Parkside Redevelopment: A Modern Steel-Framed Housing Complex

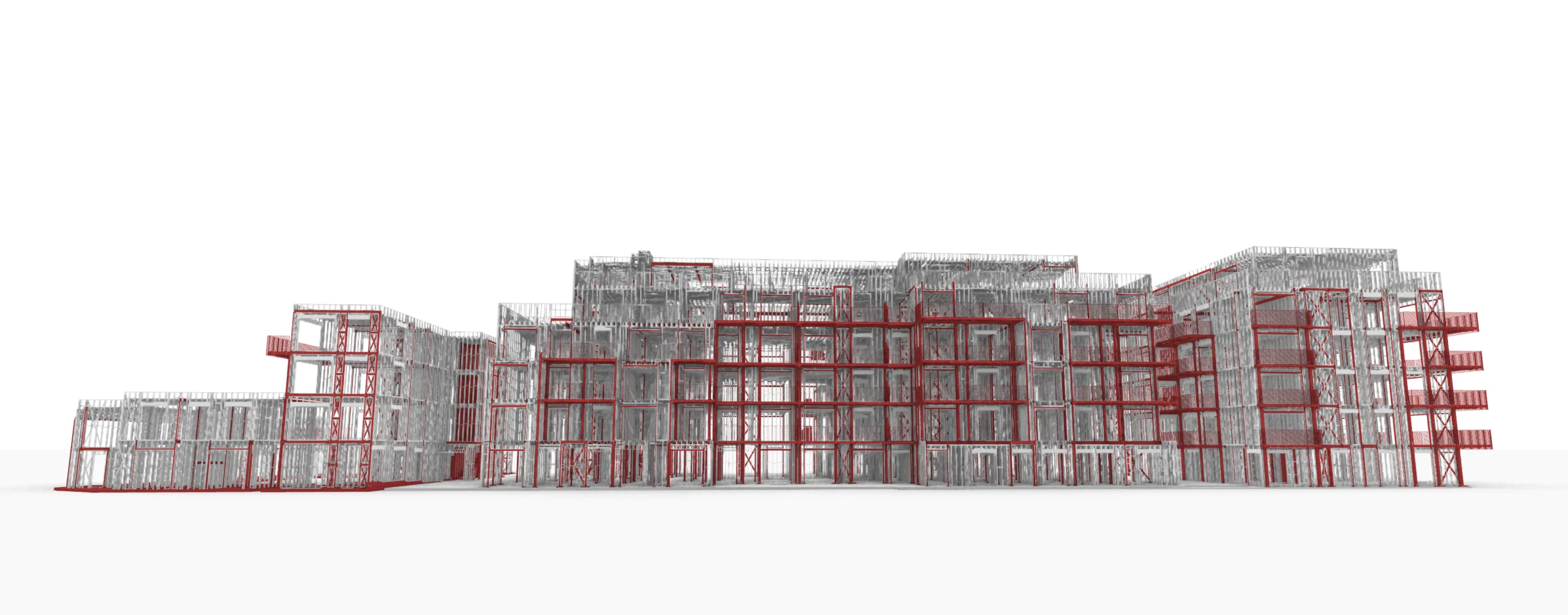

The Rye Parkside project transformed Solomon’s Passage into a safe, modern, and visually appealing residential environment. The project delivered 91 new homes across four blocks, forming a well-coordinated steel-framed housing complex designed for long-term performance. Each building was constructed using light-gauge steel framing, providing the strength, dimensional stability, and durability required for multi-story urban housing.

RDE Construction was appointed as the specialist steel manufacturer for the steel-framed development, designing, manufacturing, and supplying a £1.2 million light-gauge steel framing system. The steel framing system was selected for its precision-engineered components, lightweight structure, and compatibility with modern roll forming technology, ensuring efficient fabrication, rapid installation, and consistent build quality across the entire Rye Parkside development.

Why Developers Are Moving to Light-Gauge Steel Framing

The original Solomons Passage buildings were constructed using traditional materials and ultimately required full redevelopment due to structural shortcomings. In contrast, light-gauge steel framing offered a proven alternative capable of delivering consistent quality across the entire steel-framed housing complex.

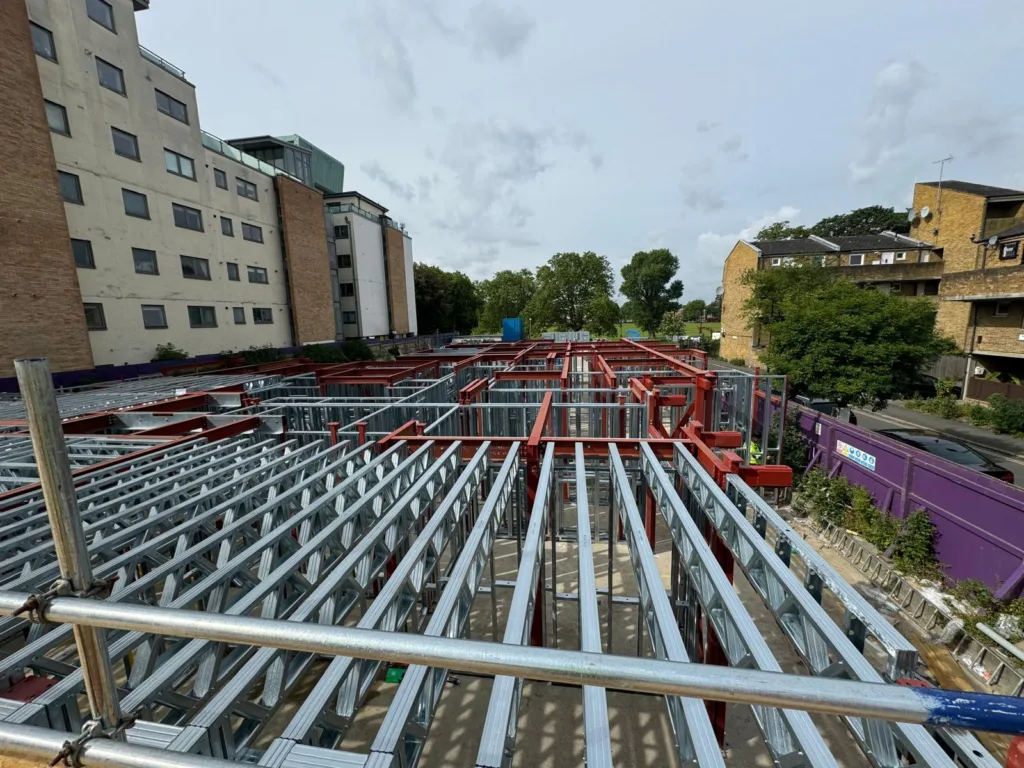

For developers, light-gauge steel framing provides predictable structural performance. Steel does not shrink, twist, or warp, eliminating many of the defects associated with timber construction. In a multi-story steel-framed development, dimensional accuracy is critical for cladding alignment, internal finishes, and service coordination. Steel framing maintains that accuracy from fabrication through installation.

Equally important, light-gauge steel framing improves buildability. Panels and systems can be designed, manufactured, and installed with repeatable precision, reducing onsite labor variability. This reliability allows developers to control schedules more effectively and reduce risk across large residential projects and developments.

Roll Forming Technology That Accelerates Delivery

The efficiency of the Rye Parkside project was driven by advanced roll forming technology. Using the Scotpanel 5090 roll forming machine, framing panels were manufactured directly from digital design data, ensuring accuracy across every wall and floor system.

Roll forming technology enables continuous, automated production of steel framing profiles, delivering consistent quality at scale. For a steel-framed housing complex of this size, that consistency translates into faster assembly and smoother trade sequencing. Panels arrive on-site ready for installation, minimizing rework and reducing congestion on constrained urban sites.

From a developer’s perspective, roll forming technology supports:

- Shorter construction programs through off-site fabrication

- Reduced reliance on skilled onsite framing labor

- Lower material waste and controlled production costs

- Improved coordination between design, manufacturing, and construction

These advantages give roll forming technology a clear edge over traditional building methods when delivering a high-density steel-framed development.

A Steel Framed Development Built for Durability and Compliance

Beyond speed, the long-term performance of this steel-framed development was a critical consideration. Light-gauge steel framing offers excellent resistance to fire, moisture, and pests, supporting compliance with UK building regulations and insurer requirements.

Steel framing also contributes to the overall resilience of the housing complex. The structural system delivers strength without excessive weight, making it well-suited for multi-story residential construction. For developers, this durability translates into reduced lifecycle costs and improved asset value.

Sustainability is another key driver. Light-gauge steel framing is fully recyclable and well-suited to controlled factory production. When paired with roll forming technology, material usage is optimized, and waste is minimized, aligning the project with modern environmental expectations.

Commercial Advantages of Steel Framing Housing Complexes

As market pressures increase, developers are seeking construction systems that deliver certainty. Projects like Rye Parkside show why steel-framed housing complexes are becoming the preferred solution for urban residential developments.

By combining light-gauge steel framing with roll forming technology, developers gain:

- Faster time to market

- Greater cost predictability

- Higher quality control

- Reduced construction risk

Rye Parkside steel-framed development demonstrates how advanced fabrication methods can replace traditional construction approaches that struggle to meet today’s demands. With the Scotpanel 5090 roll forming machine enabling precise, scalable production, the project sets a strong benchmark for future residential developments built with steel framing.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Choose the Right Roll Forming Machine

- Blog – Pricing of Wood and Steel Framed Homes Revisited: All You Need to Know

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Cold-Formed Steel Framing in High-Seismic Regions: All You Need to Know

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.