Modern roll forming operations depend on advanced technology, the right steel framing machine, and efficient hardware and software that support light-gauge steel framing systems to stay competitive. Choosing the correct equipment is not only about production speed or equipment price, but it is also about building a production platform that supports accuracy, scalability, and long-term business and operational growth.

Why Roll Forming Matters in Modern Construction

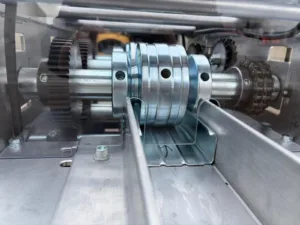

At its core, roll forming is about consistency. Manufacturers rely on roll forming to produce repeatable light-gauge steel profiles that assemble cleanly in the field and meet strict tolerances. Successful manufacturers invest in roll forming machines that deliver accuracy, repeatability, and speed across long production runs. With proper tooling and controls, roll forming supports consistent output without excessive labor or rework.

This reliability is critical as production volumes increase and project schedules tighten.

Choosing a Steel Framing Machine Built for Growth

A steel framing machine must do more than produce profiles; it must support your business as it evolves. A well-designed steel framing machine handles varying gauges, yield strengths, and profile complexity without compromising quality. Upgradable tooling allows a steel framing machine to adapt as market demand evolves, helping manufacturers expand into new applications without replacing equipment.

Investing in the right steel framing machine ensures production remains flexible, efficient, and future-ready.

Light Gauge Steel Framing and Scalable Manufacturing

Demand for light-gauge steel framing continues to grow due to durability, non-combustibility, and design flexibility. Producing light-gauge steel framing in-house gives manufacturers greater control over scheduling, quality, and material usage. By manufacturing light-gauge steel framing components directly from coil, businesses reduce waste and improve responsiveness to project changes.

As more builders adopt steel-based systems, light-gauge steel framing becomes a key driver of scalable construction.

How Roll Forming Technology Drives ROI

Today’s facilities rely heavily on software-driven roll forming technology. Integrated controls manage cut lists, punch data, and part identification, turning fabrication into a data-driven manufacturing process. Modern roll forming technology reduces manual input, minimizes errors, and supports real-time production feedback.

When paired with automation, roll forming technology increases throughput while maintaining precision, directly improving return on investment.

Building a Platform for Long-Term Success

By combining roll forming with advanced software and technology, manufacturers gain flexibility and long-term efficiency. The right steel framing machine enables light-gauge steel framing businesses to scale with confidence while maintaining quality and speed.

Investing in advanced end-to-end roll forming technology and efficient light-gauge steel framing processes creates a strong foundation for sustainable growth in an increasingly competitive construction market.

Roll Forming Machine Buyer’s Checklist

We understand that starting this process can feel overwhelming; knowing which questions to ask, which parameters truly matter, and how to fairly compare different manufacturers and roll forming machines is not always clear. That’s why we created a “Roll Forming Machine Buyer’s Checklist” to give our customers a clear starting point, helping them evaluate options with confidence and make informed, side-by-side comparisons as they move toward the right investment.

Use this checklist to evaluate whether a roll forming machine and manufacturer align with your production, quality, long-term business goals, and beyond.

- Machine Capability & Technical Fit

☐ Supports required steel thickness range

☐ Handles required yield strengths (e.g., 33 ksi, 50 ksi, 70 ksi)

☐ Produces all required profiles (current and future)

☐ Allows easy addition of new profiles

☐ Maintains tight tolerances for length, punching, and shape

☐ Designed for continuous production, not just short runs

☐ Upgrade options available (swaging, notching, dimpling, specialty punches)

- Production Capacity & Performance

☐ Meets required production speed under real-world conditions

☐ Maintains accuracy at higher speeds

☐ Proven output data from similar customers

☐ Fast and repeatable profile changeovers

☐ Automation options for stacking, labeling, or material handling

- Software, Automation & Integration

☐ User-friendly machine control software

☐ Imports files from common design/engineering platforms

☐ Automatically manages cut lists and punch data

☐ Provides part identification and tracking

☐ Real-time production monitoring and error alerts

☐ Integrates with other third-party software

- Quality, Accuracy & Repeatability

☐ Consistent dimensional accuracy over long runs

☐ Designed to handle coil variability

☐ Sample parts or reference projects available

☐ Built-in quality control measures

- Tooling, Wear Parts & Changeovers

☐ Clear list of standard vs optional tooling

☐ Long tooling life with predictable wear

☐ Quick and simple tooling change process

☐ Spare parts readily available

☐ Profile-specific tooling kits offered to reduce setup time and improve cut quality

- Installation, Training & Commissioning

☐ Turnkey installation included

☐ Defined timeline from delivery to production

☐ Operator and maintenance training provided

☐ On-site and/or remote training options

☐ Documentation and training materials for future staff

- Service, Support & Warranty

☐ Clear warranty coverage and terms

☐ Responsive technical support

☐ Remote diagnostics capability

☐ Local or regional service availability

☐ Preventive maintenance and service plans available

- Scalability & Future Growth

☐ Machine can be upgraded rather than replaced

☐ Additional tooling stations can be added

☐ Supports increased production volume

☐ Part of a broader equipment ecosystem

☐ Compatible with future machines and automation

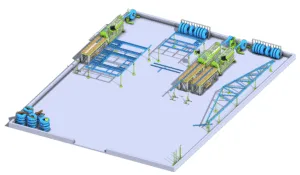

- Energy, Footprint & Facility Requirements

☐ Power requirements fit facility capabilities

☐ Reasonable energy consumption

☐ Floor space and layout clearly defined

☐ No special foundations required or clearly specified

☐ Meets safety requirements

- Business Case & Total Cost of Ownership

☐ Transparent pricing structure

☐ Clear list of ongoing consumables

☐ Predictable maintenance costs

☐ Proven ROI from similar operations

☐ Financing or phased investment options available

- Manufacturer Credibility & Track Record

☐ Established history in roll forming machinery

☐ Proven installations in similar industries

☐ Customer references available

☐ Willingness to arrange site visits or demos

☐ Clear long-term product development roadmap

Roll Forming Machine Buyer’s Tip

A roll forming machine is a long-term investment. The best decision balances technical capability, production efficiency, support, and scalability, not just the initial purchase price. Ask the right questions of your manufacturer. Scottsdale’s sales and technical team can provide answers to all the listed questions above and any additional questions that may arise.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Compare Roll Forming Machines and Clarify Misconceptions

- Blog – Understanding the Energy Consumption of Roll Forming Machines

- Blog – Overcome Complex CFS Truss Design with New Steel Framing Technology

- Blog – The Best Data-Driven Roll Forming Technology for Steel Framing Production

- Blog – ISG Frames Delivers an Epic Project with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – How to Launch a Successful Steel Framing Business

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.