At Scottsdale Construction Systems, we believe that informed decision-making builds better businesses. As a global leader in roll forming technology, we welcome open comparison of roll forming machines, steel framing equipment, and complete CFS systems. When facts are presented selectively or out of context, it only creates confusion. Our goal is transparency, helping every customer understand how cold-formed steel and modern steel framing operations can transform their business. As a trusted name in roll forming technology, we clarify misconceptions and explain why comparing roll forming machines requires a deeper look at total system performance, not just numbers or claims.

Comparing Roll Forming Machines Across the Industry

The roll forming industry includes many manufacturers, but not all steel framing machines are built equally. At Scottsdale, we provide a complete ecosystem that combines roll forming technology, engineering software, design automation, full-service support, and more. Customers can access everything from high-performance roll forming machines to supply management and financial services under one ecosystem.

Our steel framing operations are powered by several machine families. The Scotpanel and Scottruss series are single-profile roll forming machines built for producing cold-formed steel wall and truss profiles, while the KFS Framemaker and KFD Framemaker multi-profile systems handle a broader range of CFS systems applications. The Scotpanel can fabricate CFS wall panels, trusses, and joists, while the Scottruss specializes in cold-formed steel trusses using the Hat-section profile.

Claims such as “one machine can fabricate an entire building” are overly simplistic and often misleading. The right solution depends entirely on the customer’s scope, project type, and production goals. That’s why we work closely with each client to identify the best configuration, whether that means investing in a single roll forming machine or implementing a multi-machine setup that supports broader steel framing operations.

Speed, Crew, and Efficiency in Steel Framing Operations

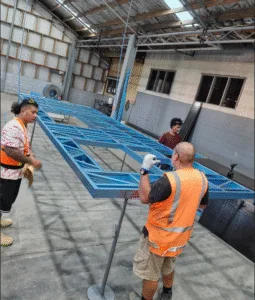

When evaluating roll forming machines, some fabricators look at production speed. However, in steel framing operations, speed alone doesn’t determine success. While roll forming technology affects precision and consistency, the true output depends on crew size, skill level, connection type, and workflow.

It’s misleading to claim one brand of roll forming machines is “30% faster” or “twice as efficient” without considering the full context. Some steel framing machines might operate at higher speeds, but crews often can’t keep pace with the machine’s output. Investing in exaggerated speed claims wastes capital. At Scottsdale, we help customers analyze their CFS systems and crew processes before investing, ensuring they maximize real-world productivity in cold-formed steel fabrication. We have a number of more in-depth articles that discuss this subject, listed below.

Article – How to Double Your Roll Forming Speed with Scottsdale

Article – A Better Inexpensive Ergonomic Steel Framing Fabrication Process

Article – Get Private Practical Training with Every Roll Forming Purchase

Article – Remarkable Results in Steel Framing with Roll Forming Technology

Article – Best Advice From Steel Framing Shops to Implement Today

Article – Expert Tips for Successfully Operating a Roll Forming Business

Article – Are You Operating at Peak Capacity?

Can One Roll Forming Machine Build an Entire Structure?

This is one of the most common questions we get in steel framing operations. The truthful answer is, it depends.

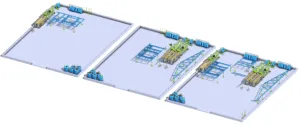

With our Scotpanel roll forming machines, customers can fabricate cold-formed steel walls, trusses, joists, stairs, and even architectural sculptures, and more, due to the Cee-section profile. The Scottruss roll forming machines are primarily designed for CFS systems that require Hat-section profiles, ideal for trusses and joists.

Our KFS Framemaker and KFD Framemaker multi-profile steel framing machines can fabricate wall panels, CFS trusses, and joist systems. Each type of roll forming technology offers different advantages depending on the customer, application, and project scale. Review some projects delivered by our customers below.

Project – Overcome Complex CFS Truss Design with New Steel Framing Technology by ISG Frames

Project – Remarkable Results in Steel Framing with Roll Forming Technology by Tag Frames

Project – How Steel Framing Delivered a Safer Ski Resort in Argentina by SICLA

Project – Innovative Disruptors in Modular Construction with Roll Forming Technology by Unipods

Project – Building Better Steel-Framed Tiny Homes with Roll Forming Technology by Mainefactured

Project – Building Better in Sacred Spaces with Roll Forming Technology by IT Steel Structure Solutions

Rivets vs. Screws in Cold-Formed Steel Fabrication

A major distinction between steel framing machines is the CFS connection type. Our Scotpanel roll forming machines are optimized to produce framing that uses rivets for connecting members, a method proven to be stronger, more consistent, and less likely to loosen than screws. Rivets enhance safety, speed up assembly, and reduce vibration in CFS systems. They also eliminate the risk of stripped threads common with screws. However, if our customers prefer to use screws or a specific project requires the use of screws, Scotpanel roll forming machines can always accommodate that.

Our Scottruss roll forming machines produce framing that uses bolted connections to manage higher load capacities in CFS truss applications. Screws, rivets, and bolts are carefully selected based on engineering performance, ensuring that all cold-formed steel joints meet or exceed structural standards for durability and precision in steel framing operations. Our customers have the freedom to select what best fits their projects, and our roll forming machines have the ability to fabricate based on the required performance and the client’s needs.

Large Commercial and Industrial Applications of Steel Framing

Scottsdale roll forming machines are used in major commercial, residential, and industrial projects worldwide. Our roll forming technology scales with your business, supporting cold-formed steel structures and complex multi-level CFS systems.

We encourage businesses to reach out with details about their markets, project requirements, and growth plans. Our experts evaluate your production goals, regional standards, and steel framing operations setup to recommend the right steel framing machines and components.

Coil Widths and Profile Variety in Roll Forming

Our roll forming machines can fabricate over 100 different cold-formed steel profiles. As a result, coil widths cannot be standardized to just a few sizes. “Standard coil width” claims can be misleading as geography, supplier, and profile geometry all contribute to coil availability.

Scottsdale provides clear coil data with every machine, along with guides and resources available through our downloads and operational supply pages. Our roll forming technology enables flexibility, supporting diverse CFS systems and optimizing steel utilization at every production cycle.

If coil management or space optimization is a priority for your operation, our team will collaborate with you to develop the most efficient solution for your manufacturing environment. We’ve published several in-depth articles on this topic, which you can explore below for additional insights and best practices.

Article – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

Article – How to Launch a Successful Steel Framing Business

Article – Reasons to Invest in a Multi-Profile Roll Forming Machine

Article – Informative Guide to Corrosion Resistance of Steel Framing

Article – The Critical Role of Coil Selection in Steel Frame Building

Article – Know How to Order Steel Coils for Roll Forming Operations

Article – Power Source Options in Advanced Roll Forming Technology

Global Support and Knowledge Resources for Steel Framing Fabrication

Scottsdale provides 24-hour global support for all roll forming machines. Our team assists customers across hardware, software, engineering, and operational setup. We maintain a comprehensive KnowledgeBase with videos, technical bulletins, and articles that cover every aspect of cold-formed steel framing and roll forming technology.

This support infrastructure ensures that our customers’ steel framing operations stay online and efficient, maximizing uptime for every roll forming machine in production.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Compatibility and Integration in Roll Forming Technology

Modern fabrication requires digital integration. Our roll forming technology ecosystem is compatible with major platforms, including Sketchfab, Revit, Strucsoft MWF, Vertex BD, Bentley, CFS, SpaceGass, Strap, CSI, Keymark, Connex, Eclipse, AutoCAD, Tekla, Loseke, Oracle, Sage, SAP, and more. These tools connect seamlessly with our steel framing machine ecosystem for end-to-end design-to-production automation. If a customer’s preferred tool isn’t listed, we encourage them to contact us as we frequently expand compatibility to fit evolving CFS systems.

Multi-Profile Roll Forming Machines for Every Application

Scottsdale offers multi-profile roll forming machines under the Knudson by Scottsdale brand. The KFS Framemaker, KFD Framemaker, and KSE families each serve distinct roles in steel framing operations.

KFS Framemaker: Produces structural lipped and unlipped C-sections for load-bearing cold-formed steel applications up to ten stories, ideal for wall panels, load-bearing partitions, and modular CFS systems. View KFS Framemaker profile details below.

KFD Framemaker: Produces non-structural profiles for interiors, ceilings, and facades, which are ideal for low to mid-rise steel framing projects. View KFD Framemaker profile details.

KSE: Specialized roll forming technology for roofing and auxiliary framing beyond traditional Cee- or Hat-sections. View KSE Framemaker profile details.

These multi-profile steel framing machines demonstrate our commitment to scalable, automated, and intelligent steel framing operations that support builders worldwide.

A Transparent Ecosystem and the Future of Steel Framing

Scottsdale Construction Systems remains an end-to-end solution provider for cold-formed steel and CFS systems fabrication. We prioritize data, transparency, and customer success. Our steel framing machines and integrated roll forming technology continue to set the benchmark for modern steel framing operations.

When you invest in Scottsdale roll forming solutions, you’re investing in precision, productivity, and proven experience. We invite you to explore our machines, request technical documentation, and contact our team to make confident, informed decisions about your cold-formed steel production needs.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – New! Introducing the Next Generation of KFS Roll Forming Machines

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Blog – Extra Insurance Savings and Premiums Delivered with Steel Framing

- Blog – The Best Data-Driven Roll Forming Technology for Steel Framing Production

- Blog – ISG Frames Delivers an Epic Project with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – Power Source Options in Advanced Roll Forming Technology

- Blog – Understanding the Energy Consumption of Roll Forming Machines

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.