At METALCON 2025, Scottsdale Construction Systems demonstrated how advanced roll forming technology and precision steel framing machines are transforming the global construction industry. From concept to completion of a full-scale steel-framed home, Scottsdale showcased the power of cold-formed steel and the efficiency of automated steel framing fabrication. The event brought together innovators, builders, and engineers who witnessed firsthand how roll forming continues to push the boundaries of strength, speed, and sustainability in construction. With a focus on advanced machinery, integrated software, and field-ready engineering, Scottsdale’s presence at METALCON reaffirmed its position as a global leader in roll forming solutions for modern steel framing fabrication.

Showcasing Roll Forming Technology Excellence at METALCON

Opening Presentation: Shaping the Future of Steel Framing

On Day 1, shortly after the official ribbon-cutting ceremony at METALCON, JR Mujagic delivered an inspiring short-form presentation right in front of Eagles Landing, the centerpiece steel-framed home built with Scottsdale’s steel framing machines. The conversation introduced attendees to Scottsdale’s heritage in roll forming technology and its role in advancing cold-formed steel construction. JR Mujagic highlighted how Scottsdale’s roll forming solutions empower fabricators to achieve greater precision, efficiency, and consistency in steel framing fabrication.

Industry leaders left the presentation with a clear understanding of how roll forming innovation is shaping the future of steel framing and modern construction. The discussion emphasized not only the power of Scottsdale’s advanced roll forming machines but also the value of its integrated software ecosystem that drives data-driven steel framing fabrication.

Main Presentation: Advances in Cold-Formed Steel and Roll Forming Solutions

On Day 2, Virginia Delucchi, Education and Certification Manager, delivered a one-hour presentation to a packed audience. Her session explored the latest advancements in cold-formed steel and roll forming technology, highlighting automation breakthroughs, improved material handling, and increased production speeds.

Attendees learned how steel framing machines and containerized fabrication factories are reducing transportation costs and improving project turnaround times. Virginia Delucchi demonstrated how these innovations enhance the competitiveness of fabricators through smarter roll forming solutions, better throughput, and streamlined steel framing fabrication.

The presentation also covered:

- Automated roll-forming processes that reduce labor costs

- Enhanced material handling systems for efficient workflow

- Containerized roll-forming factories for onsite production

- Technology integration for long-term productivity

Her talk reinforced how combining cold-formed steel with intelligent roll forming technology delivers unmatched precision and scalability, allowing builders to produce steel-framed homes faster and more efficiently than ever before.

Watch a recap of Scottsdale’s greatest moments at METALCON 2025.

A Landmark Event for Roll Forming and Steel Framing Machines

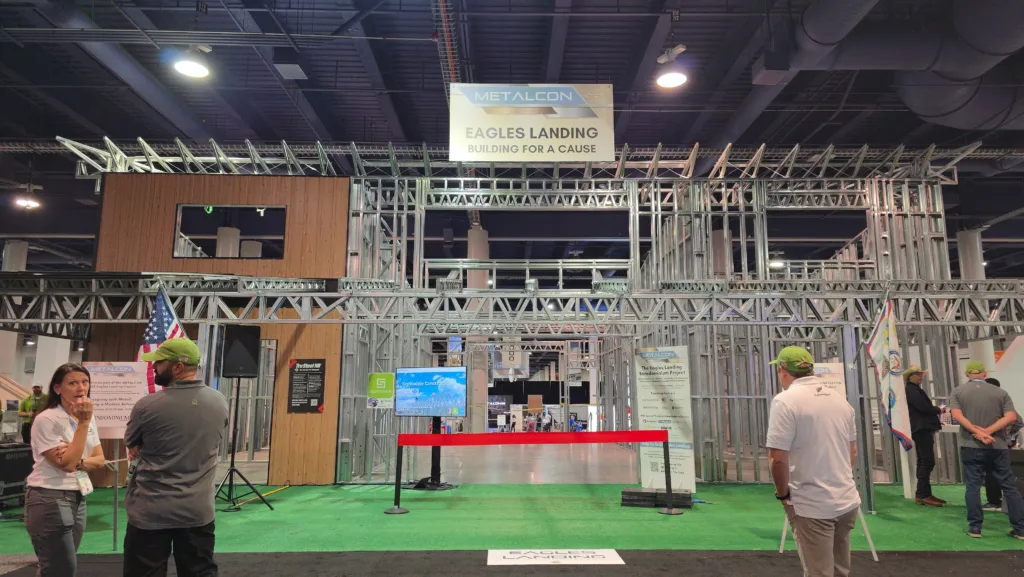

METALCON 2025 exceeded all expectations with record attendance, exceptional engagement, and strong industry enthusiasm for metal construction and roll forming solutions. Foot traffic throughout the event was remarkable, as visitors filled Scottsdale’s booth to learn how our steel framing machines drive innovation in cold-formed steel construction.

The energy in the exhibition hall was electric. Industry professionals, builders, and media representatives, including Coffee Shop Crew-MetalCoffeeShop, Fabrication Nation Radio, and Metal Architecture, explored the showcased steel-framed home, Eagles Landing. Interviews and features will soon follow, highlighting how roll forming solutions continue to redefine modern construction.

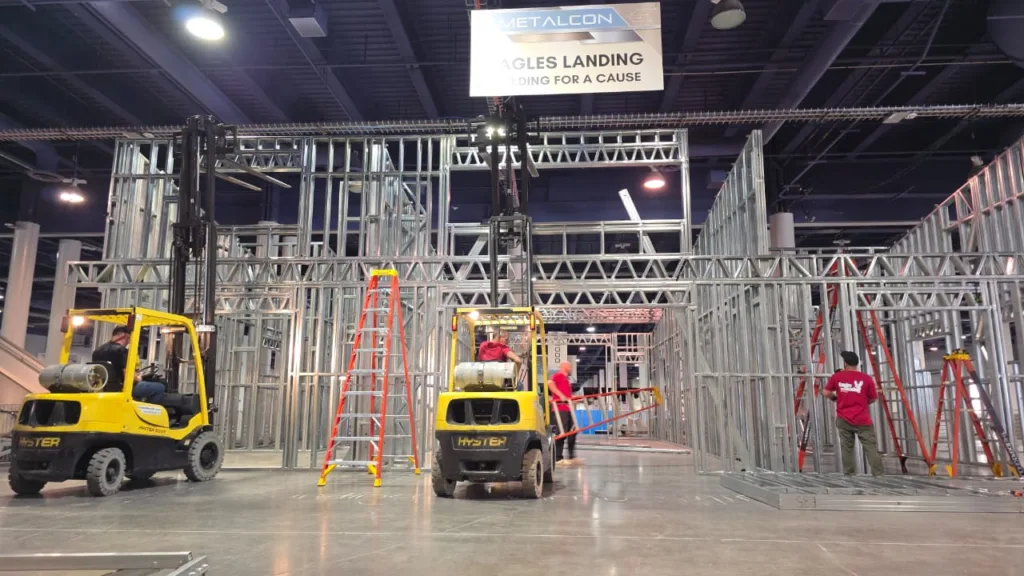

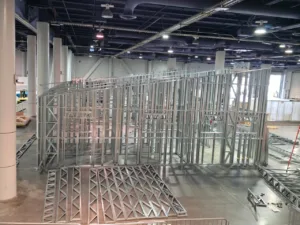

Front and center at the exhibition, Eagles Landing became the undisputed highlight of METALCON 2025. This full-scale steel-framed home captivated attendees, who were astonished by its fabrication timeline, design precision, and the strength of light-weight cold-formed steel.

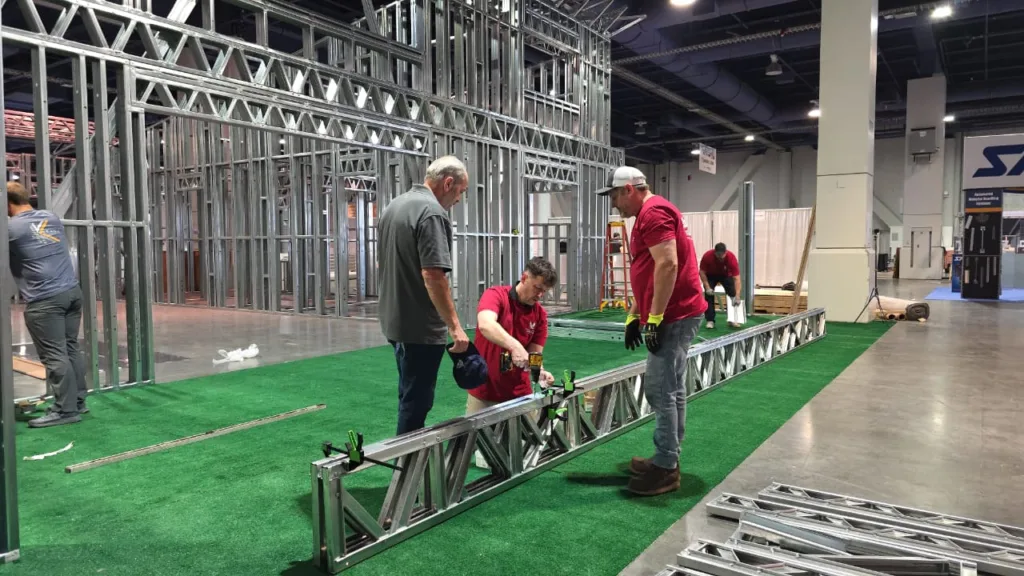

The structure was fabricated in just 1.5 days using Scottsdale’s roll forming machines: the Scotpanel 5140G2, Scotpanel 7090G2, and Scottruss 6050G1. By intentionally integrating a range of roll forming solutions, Scottsdale demonstrated how its diverse equipment line supports every aspect of steel framing fabrication, from wall panels to trusses and beyond.

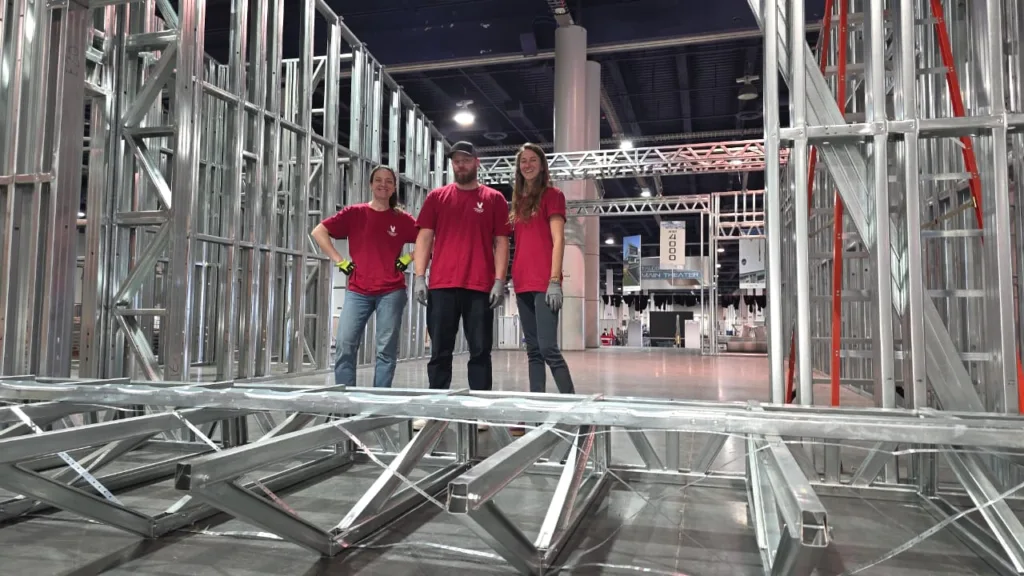

Assembly was completed in only two days with the help of six volunteers, and the entire structure was disassembled in under six hours to prepare for shipment to its final destination in Montana.

Every visitor marveled at the precision, speed, and elegance of the cold-formed steel frame, a testament to what can be achieved through world-class roll forming technology and the commitment of a skilled team.

Recognizing the Team Behind Eagles Landing’s Steel Framing Fabrication Success

The success of METALCON 2025 and the Eagles Landing showcase would not have been possible without the dedication of Scottsdale’s talented team and industry partners. Special thanks go to Derek McSpadden, JR Mujagic, Mariana Guerra, Virginia Delucchi, Cydney Skeens, Sabrina Steele, Byron Fergus, John Burns, Tom Russ (Greenbuilt Steel Structures), and Mario Fierro (Fierro Metal) for their exceptional efforts in the fabrication, assembly, and teardown of the steel-framed home.

A heartfelt thank you also goes to Mateo Camara, who designed the Scottsdale booth specifically for METALCON 2025, creating a vibrant environment to gather across Eagles Landing and reflect on what is achievable with steel framing machines and smart roll forming solutions.

Additional collaborators who helped make this an unforgettable event include:

- METALCON

- Military Warriors Support Foundation

- The Barndominium Company

- Kyle McGuire (Velent Steel Structures)

- Karen Wolpert (Matandy Steel Services)

- Rival Holdings

- KLB Steel

Together, we brought roll forming technology to life and demonstrated the limitless possibilities of cold-formed steel and steel framing fabrication.

Strength in Collaboration: A Message from Our President

“METALCON 2025 was more than an exhibition—it was a defining moment for Scottsdale Construction Systems and everyone who helped bring the Eagles Landing project to life. Together, we achieved something extraordinary: designing, fabricating, assembling, and then disassembling a full-scale steel-framed home right on the show floor in just a few days. Every task, from placing clips and standing panels to welcoming visitors, reflected teamwork, innovation, and pride. This project stood as a centerpiece of the event and a powerful demonstration of what cold-formed steel construction can accomplish. Most importantly, it carried a greater purpose—honoring veterans and their families through the spirit of Eagles Landing.

This build was a living expression of Scottsdale’s mission to empower construction. It proved that building isn’t just about materials—it’s about people coming together to create lasting impact. Through precision roll-forming machines, intelligent design software, and a global ecosystem built on trust and partnership, we continue to make construction easier, smarter, and more connected than ever before. Eagles Landing embodied that vision: architects, engineers, and fabricators working seamlessly through our digital ecosystem, from design to roll-forming to assembly. What happened on the METALCON floor wasn’t merely a showcase of technology—it was a testament to collaboration, purpose, and the belief in what’s possible when passion meets precision.

We extend our heartfelt thanks to every participant, partner, and visitor who shared in this moment with us at METALCON 2025. Together, we didn’t just build a home—we built a story of innovation, gratitude, and the future of construction.”

Derek McSpadden, President of Scottsdale Construction Systems

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How Steel Framing Roll Forming Technology is Helping Veterans

- Blog – New! Introducing the Next Generation of KFS Roll Forming Machines

- Blog – How to Make Walls and Ceilings with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – Understanding the Energy Consumption of Roll Forming Machines

- Video – The Best Containerized Factory Solution for Remarkable Steel Homes

- Video – Unlimited Possibilities with Scottruss High-Tech Roll Forming Machine

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.