In modern construction, roll forming machines have redefined how contractors approach steel framing technology. For curtain wall contractors and professionals fabricating walls and ceilings, these innovations deliver precision, speed, and efficiency unlike any traditional process. By integrating advanced roll forming equipment, including the KFD Framemaker 2025, KSE K35C, and FrameExtend 24, builders can fabricate complete walls and ceilings directly from digital designs. Together, these tools form an intelligent ecosystem for steel framing production that’s efficient, accurate, and scrap-free.

Industry-Leading Steel Framing Technology

Scottsdale Construction Systems and Knudson by Scottsdale have developed industry-leading steel framing technology designed to automate and enhance every step of fabricating walls and ceilings. The seamless integration between design software and roll forming machines enables digital-to-physical production, essentially 3D printing in steel.

The result? Every component is produced with exact dimensions, punched openings, dimples, and service holes, ready for assembly. For curtain wall contractors, this means each profile is fabricated, labeled, and sequenced automatically, ensuring every steel framing member fits perfectly into place without rework.

Scottsdale Construction Systems was featured in the Nov/Dec 2025 issue of Construction Dimensions (Page 25 of 92).

Roll Forming Machine Highlights

Walls and Ceilings Roll Forming Equipment

For walls and ceilings contractors, to fully leverage this steel framing technology, only three roll forming machines are needed:

KFD Framemaker 2025 Roll Forming Equipment

A multi-profile roll forming machine for fabricating nonstructural steel framing members, C-sections (studs) and U-sections (tracks), of non-load-bearing steel framing solutions in commercial and residential projects for partition walls, suspended ceilings, facades, and more.

Learn more about the KFD Framemaker 2025.

KSE K35C Roll Forming Equipment

A roll forming machine designed to meet project needs for non-structural steel framing sections. The KSE K35C roll forming machine fabricated a variety of furring channels and resilient furring channel sections. Learn more about Furring Channels: Ultimate Guide to Benefits and Uses.

Learn more about the KFE K35C cassette options.

FrameExtend 24 Roll Forming Equipment

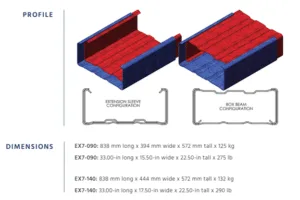

Also known as the Extension Sleeve Unit, is an auxiliary roll forming machine used to turn a preformed C-section into a smaller C-section that will fit inside the original part. The machine reduces the overall member’s dimensions, both in the web and flange, by approximately 2.5 mm, which results in a sleeve that can be slid inside the part with the original dimensions. See images below for additional dimensions and information.

The parts can be used to create telescoping (extendable studs) or to create boxed beam sections. A telescoping wall panel system expands fabrication possibilities for large-scale steel framing projects and custom assemblies. Boxed beam sections can be used for posts, traditional headers, and any other application where additional strength or a closed member is required.

Learn more about FrameExtend 24 by reviewing How Does Innovative FrameExtend24 Work and Your Construction with FrameExtend 24: The Perfect Fit, Every Time.

Learn more about FrameExtend 24.

Why Fabricating Walls and Ceilings Is Simple

Using Scottsdale’s steel framing technology, fabricating walls and ceilings is as simple as assembling LEGO pieces. The software handles every instruction, from design sequencing to member fabrication, so installers only need to follow labeled components. With automation guiding each stage, the process eliminates manual errors and ensures that every component matches the final design.

Fast, Efficient, and Accurate Steel Framing Solutions

Speed and precision define Scottsdale’s roll forming machines. By removing the need for rework, roll forming equipment completes production faster than manual fabrication. Each steel profile emerges ready for assembly, punched, swaged, and cut to 1/16 in. accuracy. Because all information flows digitally from software to machine, even complex walls and ceilings can be produced rapidly without compromising quality.

Sustainable and Scrap-Free Roll Forming Technology

In an era of sustainability, this steel framing technology minimizes waste. With intelligent software controlling production, less than 1% of material is lost during fabrication, and that remaining scrap is fully recyclable. For curtain wall contractors and builders focused on green initiatives, roll forming machines represent one of the most efficient and sustainable ways to deliver high-performance steel framing systems.

Intelligent Design Integration with Steel Framing Machines

The combination of design software and roll forming machines allows full panelization of walls and ceilings, from resilient channels and corner beads to custom framing profiles. Telescoping wall panels, accurate placement of dimples, and engineered deflection slots all come standard, ensuring every frame meets performance and architectural requirements.

The project above highlights the capabilities of roll forming equipment in fabricating walls and ceilings. Learn more about the steel church project fabricated by Knudson by Scottsdale roll forming equipment.

Why Curtain Wall Contractors Should Invest in Roll Forming Equipment

If you’re a curtain wall contractor still relying on suppliers for fabricated steel framing components, it’s time to rethink your process. Owning your own roll forming equipment means controlling your timelines, quality, and profit margins. You’ll eliminate the delays and modifications that come with third-party supply and gain the ability to produce precise, panelized walls and ceilings in-house.

Contact Scottsdale Construction Systems to discuss how Knudson by Scottsdale roll forming machines and advanced steel framing technology can transform your operations, reduce waste, and give you a competitive edge in modern construction.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Blog – Grow Your Competitive Edge with In-House CFS Fabrication

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – The Best Data-Driven Roll Forming Technology for Steel Framing Production

- Blog – How to Launch a Successful Steel Framing Business

- Blog – 7 Roll Forming Steel Framing Advantages You Need to Know

- Blog – Empowering New Steel Framing Businesses: From Startup to Success

- Video – How FrameExtend Works: The Ultimate Panelizing Enabler for Curtainwall Contractors

- Video – Knudson by Scottsdale KFD Framemaker 2025 Roll Forming Machine

- Video – KSE K35C: A Powerful Roll Forming Machine of Miscellaneous Components

- Video – Instructional Video of Cassette Exchange on the K35C Roll Forming Machine

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.