Jump to Section

Cold-formed steel framing is an essential component of modern construction, even in buildings primarily constructed with wood, concrete, or masonry. Light-gauge steel elements such as furring channels, U-struts, and corner beads are crucial for the reliable attachment of nonstructural finishes to complete the building. Additionally, resilient furring channels which is a subset of the furring channels play a vital role in improving the performance of the building envelope, particularly by reducing sound transmission. This article delves into the use cases, applications, and benefits of furring channels and their variations in detail.

Furring Channels: Applications and Use Cases

Furring channels are versatile and can be used in a wide range of applications, regardless of the building type. They are suitable for residential, commercial, and industrial projects, where they effectively meet soundproofing requirements and support various cladding types. Some common applications of these channels include:

- concrete slabs,

- blockwork walls,

- suspended ceilings,

- underfloor joists,

- under roof/floor trusses,

- timber framed walls, and

- structural columns and beams.

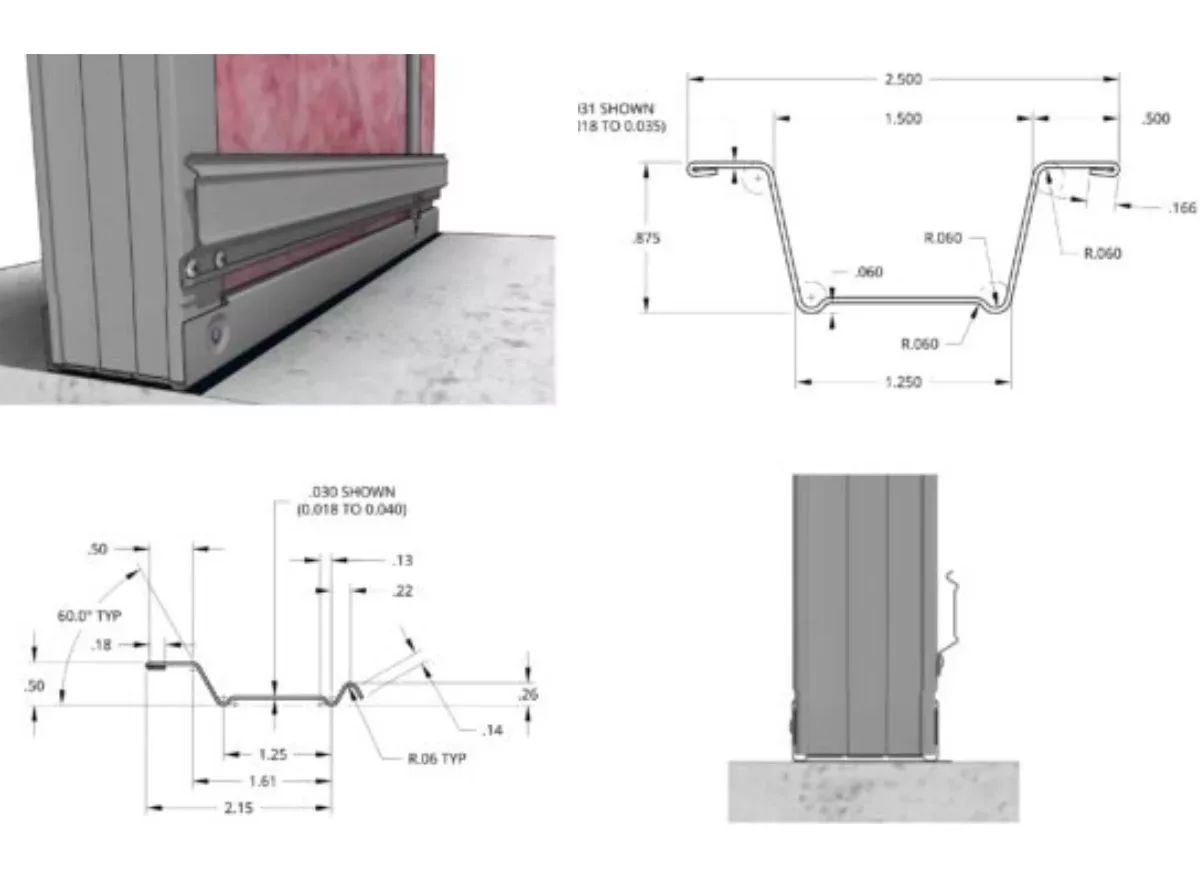

It is to note that resilient furring channels are used primarily in wall applications while furring channels are used in a variety of other places. The applications are virtually limitless and depend on the specific requirements of the project. The images below illustrate typical use cases of resilient furring channels.

Installation of Furring Channels

As described earlier these channels are installed by screwing them onto structural elements. Depending on the section type, one or both flanges of the channel are used to fasten them onto the studs. Furring channels are fastened using both flanges while the resilient furring channels are fastened using one flange. The structural framing can be either metal or wood, depending on the project specifications. Self-piercing fasteners are typically used for installing the furring channels in case of metal framing while other fastening to wood or concrete substrate happens with respective connectors. The thickness and spacing of these channels depend on the type of cladding and the load applications. For heavier cladding, a thicker channel may be required. Similarly, if the loads induced on the studs by the cladding are higher, closer channel spacing might be necessary.

Furring channels are often used in systems where fire ratings are critical as well. In such cases, careful consideration must be given to ensure that the channels contribute to achieving the required Fire Resistance Levels (FRLs) as per the project specifications. These systems are typically complemented with fire-rated sealants at the corners of walls, floors, and roofs to meet the specified FRLs. The usage of furring channels in fire rated wall systems prohibits the fire to directly affect the hot flange of the wall systems thereby increasing the FRLs. Resilient furring channels may also be used in some less critical applications given the thickness of the channels in comparison with furring channels.

For detailed guidance on FRLs and acoustic ratings for different systems, refer to “”A guide to Fire & Acoustic Data for Cold-Formed Steel Floor, Wall & Roof Assemblies“ by SFIA.

The image below illustrates a typical installation detail of a resilient furring channel on metal framing.

Strength Prediction and Buckling Modes

Predicting the strength of furring channel sections is crucial for ensuring their structural adequacy in real-world applications. Determining the maximum spans and spacings for specific loads is essential to calculate the quantity of channels required for a project. The “AISI S200-20 North American Standard for Cold-Formed Steel Nonstructural Framing” outlines the Effective Width and Direct Strength Methods for designing resilient furring channel members. Typically, manufacturers provide span tables detailing the spans and strengths for various loading conditions, which designers can use to specify the required sections for their projects.

The guide “A Guide to Fire & Acoustic Data for Cold-Formed Steel Floor, Wall & Roof Assemblies” by SFIA offers typical section details and spans for commonly used furring channels and resilient furring channels under various loading conditions. It is important to note that not all furring channels are the same. Therefore, project designers must carefully select the appropriate furring channel designation to meet the project’s acoustic, structural, and fire load requirements. Numerous research studies have been conducted on various furring channels and resilient furring channels to evaluate their performance in wall systems. Click here to know more about these research findings.

Like other cold-formed steel sections, furring channels are prone to various buckling modes, with distortional buckling often being the predominant failure mode. Structural designers must consider these buckling behaviors when designing systems that incorporate these channels.

The image below illustrates typical distortional buckling behavior in a furring channel section.

Building Standards and Their Guidelines on Furring Channels

Specifications for furring channels, classified as non-structural steel framing, are outlined in the “AISI S220-20 North American Standard for Cold-Formed Steel Nonstructural Framing”. Standard dimensions, including web depth, flange width, inside bend radius, and lip length, are defined to ensure compliance with industry requirements. These standards also specify the different types of furring channels, its subsets that are commonly used within the industry. All sections produced by our roll formers adhere to these specifications, maintaining the highest standards of compliance.

The “ASTM C645-18 Standard Specification for Nonstructural Steel Framing Members” also provides guidelines for non-structural steel framing members. This standard specifies details about the connection between furring channels and plasterboard, ensuring proper installation practices. Additionally, it outlines the physical tests required to verify the conformity of furring channels produced by roll formers.

The image below illustrates these specifications in detail.

How can I use Furring Channels in my Next Project?

The Knudson by Scottsdale KSE family of machines offers a wide range of rollformers designed to meet the needs of your upcoming project with regards to nonstructural cold-formed steel sections. The KSE Series rollformers have demonstrated their durability for decades, setting a benchmark in the rollforming industry for manufacturing furring channel and resilient furring channel sections.

All our rollformers are capable of producing industry-standard SFIA shapes, including commonly used furring channel and resilient furring channel sections, in full compliance with ASTM C645-18.

Complete details about all furring channels, resilient furring channels and other nonstructural sections can be found in the resources section of our website. Click here to learn more.

If these furring channels, resilient furring channels and other nonstructural sections are of interest in your upcoming projects, reach out to us at sales@scottsdalesteelframes.com or dial +1 (888) 406-2080 (Option 1) or dial +61 1300 671 345. Our team of experts is ready to assist you in setting up your cold-formed steel manufacturing facility with ease.