In the world of cold-formed steel construction, speed, safety, and precision are everything. That’s why Scottsdale Construction Systems has revolutionized steel framing fabrication by designing the fastest panelizing process on the market, delivering safer and more efficient steel framing assembly through a system that combines advanced roll forming machines, ergonomic fabrication stands, and a rivet-based connection method. Unlike traditional methods that rely on static tables and screw-based systems, Scottsdale eliminates unnecessary steps and streamlines the entire steel framing workflow, from roll forming to final assembly.

Roll Forming Machines That Deliver Immediate Results

At the heart of Scottsdale’s system are its roll forming machines, engineered to produce cold-formed steel components with precise cuts, notching, and dimpling already in place. As each profile exits the roll former, it can immediately be positioned on ergonomic fabrication stands for assembly. This means no wasted time threading each stud through continuous nogs or transferring profiles to different workstations.

This immediate transition from roll forming to steel framing assembly is one of the main reasons Scottsdale’s panelizing process is significantly faster than that of competitors. No flipping, threading, or re-positioning required, just efficient, uninterrupted progress.

Why Ergonomic Fabrication Stands Are Important

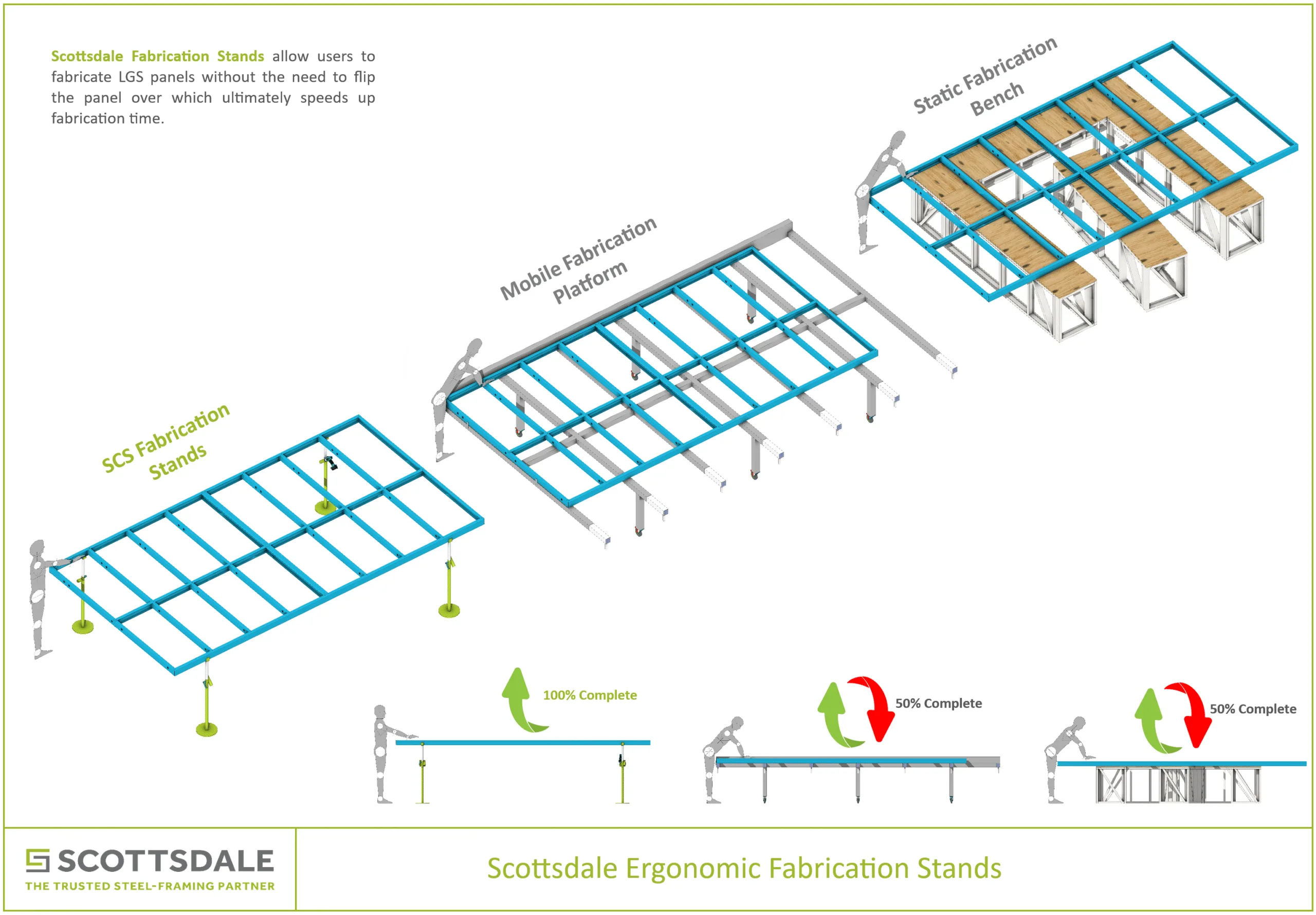

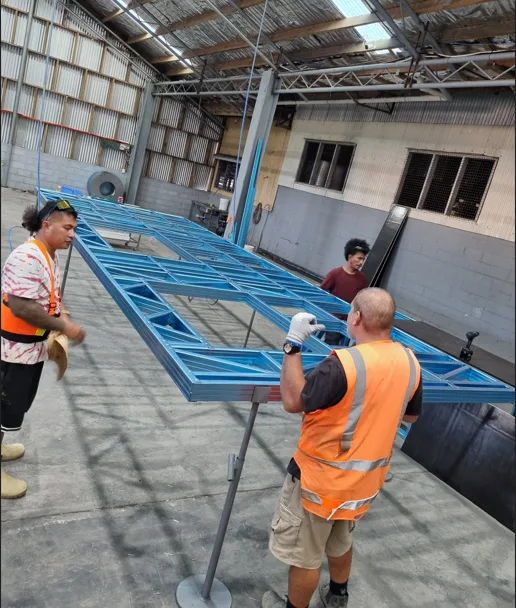

Scottsdale’s steel framing fabrication stands are not just another tool; they’re a productivity multiplier. Traditional steel framing assemblies often rely on static tables or mobile fabrication platforms that force workers to bend, reach, or operate in cramped conditions. These setups take up valuable space and often introduce physical strain or safety hazards.

In contrast, Scottsdale’s fabrication stands are:

- Lightweight and Portable – They fit in the boot of a car, can be carried in an elevator, and are ideal for remote or compact worksites.

- Adjustable in Height – Crew members can tailor the height to reduce stress on the back, arms, and shoulders, creating a safer and more comfortable work environment.

- Space-Efficient – Unlike static tables, these stands don’t clutter the shop floor, allowing for greater layout flexibility and improved coordination during steel framing assembly.

With these stands, teams can work closer to the panel from any angle, easily access connection points, and assemble frames of any shape, without the physical limitations or safety concerns.

See images below of Scottsdale’s ergonomic fabrication stands compared to other assembly options in the industry.

Scottsdale Construction Systems has a large library of cold-formed steel detailing documents and roll forming documents available on our KnowledgeBase platform.

For more cold-formed steel fabrication and roll forming insights, visit us at https://knowledge.scottsdalesteelframes.com/.

Doubling Productivity with Rivet-Based Cold-Formed Steel Assembly

One of the biggest differentiators in Scottsdale’s steel framing system is the use of structural rivets instead of screws. This change makes a profound difference in cold-formed steel fabrication:

- Fastening from Both Sides – Rivets can be applied to both the top and bottom of the panel without flipping the panel.

- Panel Flipping Not Required – Traditional screw-based systems require manual panel flipping, which not only doubles the fabrication time but introduces safety and ergonomic risks, especially when accessing fasteners located in the center of the panel.

- Better Workflow Coordination – Operator and riveters can work simultaneously, keeping the entire assembly process in motion without interruption.

This rivet-based system drastically reduces handling time and fatigue. Teams stay focused and productive, minimizing interruptions and improving daily output without the strain of awkward positions or repetitive flipping. By eliminating these constraints, Scottsdale’s rivet-based panelizing system allows teams to work continuously, more ergonomically, and with fewer interruptions—doubling productivity within a single shift.

Learn more about Scottsdale’s rivet-based steel framing and the benefits of using rivets by reading our blog “All You Need to Know About Rivets vs. Screws”.

See how industry experts respond to the speed and simplicity of riveted connections in the video below, “Fast and Easy Riveting in Cold-Formed Steel Framing”.

Efficiency in Steel Framing Assembly with Ergonomics

When workers are comfortable, they work better and more safely. Scottsdale’s cold-formed steel assembly process reduces fatigue, avoids repetitive strain injuries, and improves coordination between fabrication crew members. The ergonomic setup supports sustained output over longer shifts and minimizes downtime due to worker discomfort or injury.

Scottsdale’s customers consistently report that the fabrication stands are simple yet effective. They enable continuous production of steel frames with improved speed, reduced labor stress, and better safety outcomes, both short and long term.

The Future of Steel Framing Fabrication

Scottsdale’s integrated system of roll forming machines, ergonomic fabrication stands, and rivet-based steel framing assembly is changing the way cold-formed steel is fabricated. By eliminating inefficiencies and focusing on worker-friendly design, Scottsdale helps builders complete projects faster, safer, and more profitably.

From mobile job sites to permanent factories, Scottsdale delivers a steel framing solution that leads the industry in quality, innovation, and productivity.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Double Your Roll Forming Speed with Scottsdale

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Blog – Practical Guide to Web Openings in Cold-Formed Steel Framing

- Video – Advantages of Riveted Steel Framing with Scottsdale’s Technology

- Video – Expert Light-Gauge Steel Wall Design, Engineering, Fabrication, & Erection

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.