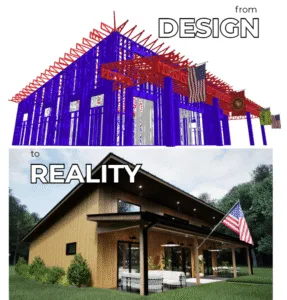

The construction industry is rapidly shifting toward cold-formed steel as the backbone of efficient, precise, and sustainable building solutions. Unlike traditional building materials, cold-formed steel design allows engineers and builders to optimize every stage of a project, from initial concept through to fabrication and assembly. Central to this transformation is the integration of advanced steel framing design software with high-performance roll forming machines, ensuring that every element of a structure is engineered for strength, speed, and accuracy.

At Scottsdale Construction Systems, we provide an end-to-end roll forming steel framing ecosystem that blends powerful software with cutting-edge hardware. Our platform brings together design, analysis, and production under one seamless workflow, eliminating inefficiencies and reducing costly errors often seen in manual transitions.

Steel Framing Design Powered by ScotSteel

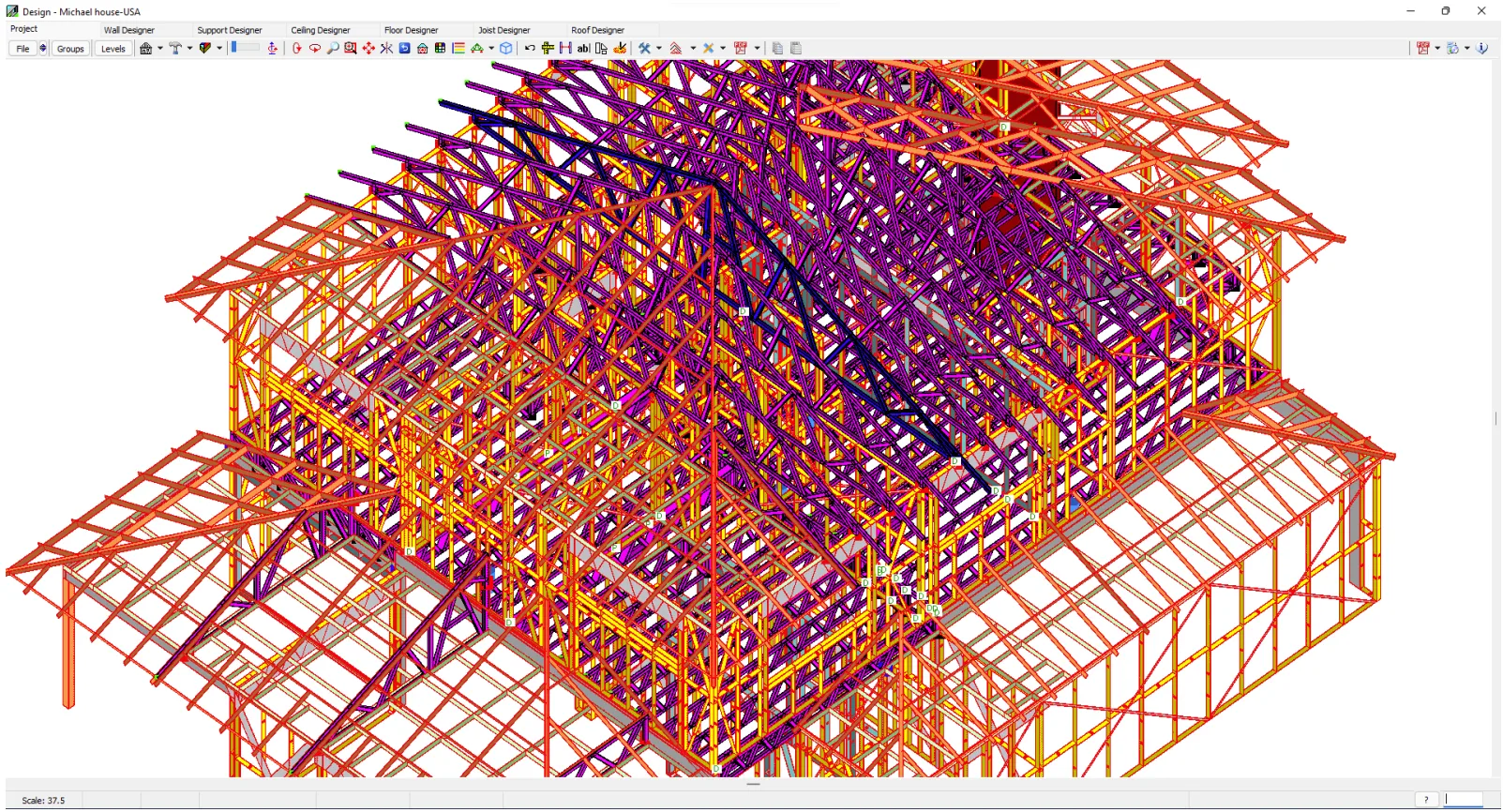

Our design software, ScotSteel, revolutionizes the way architects and engineers approach steel framing design. The software enables precise modeling of cold-formed steel sections in 2D and 3D, with built-in import tools for architectural drawings and export features for accurate quantity take-offs.

ScotSteel software enhances cold-formed steel framing design by delivering powerful features that streamline every stage of the process. Its automated design functionality allows for the rapid creation of elements such as walls, roofs, trusses, ceilings, floors, gable panels, and soffit panels, ensuring faster and more precise steel framing. The integrated component library supports a wide range of doors and windows, making roll forming steel framing easier to customize for different project requirements.

With its plate generation function, ScotSteel simplifies the design of lintels, X-bracings, and both vertical and horizontal bracings, further strengthening the reliability of cold-formed steel projects. The design check functionality identifies overlapped members, unjoined members, and potential collisions, improving accuracy before production begins.

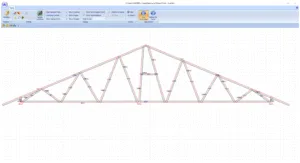

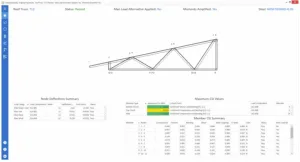

Advanced finite element analysis of trusses and panels provides deeper insight into structural performance, while comprehensive engineering reports, both general and detailed, member-by-member and node-by-node, validate the engineering integrity of each project. To complete the workflow, a bill of materials is automatically provided prior to production, ensuring that every roll forming machine operation is optimized for efficiency and precision in steel framing design.

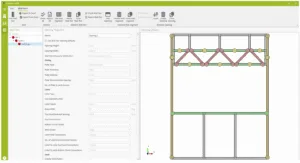

By simulating the actual functions of a roll forming machine, ScotSteel allows users to visualize connections and assemblies before fabrication. This ensures every piece of roll forming steel framing aligns perfectly with production requirements.

ScotSteel Design and Engineering Features

ScotSteel can perform wall design, floor design, ceiling design, roof design, and truss design. There are different modules built into ScotSteel, each targeting a specific design and engineering task.

Some key design and engineering features include:

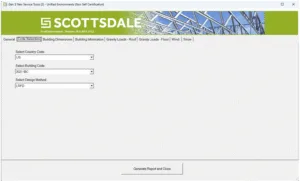

- Defining the engineering environment of a project by specifying job location and project parameters to autogenerate gravity loads, wind loads, and snow loads to be used in engineering calculations.

- Generating truss engineering calculations per major building codes. Running structural analysis on truss design using finite element modeling and reporting strength and serviceability checks in accordance with country/region-specific design standards.

- Generating seismic data based on project location and performing shear calculations based on ASCE7.

- Producing onsite installation documents and engineering verification documents.

- Providing virtual representation of roll former’s physical functionality to view joints and connections on a single frame.

Cold-Formed Steel Design and Fabrication with ScotStruct and ScotRF

Beyond drafting and visualization, cold-formed steel design requires rigorous engineering analysis. ScotStruct integrates seamlessly with ScotSteel to provide advanced structural checks, including wind, seismic, gravity, and snow load calculations based on regional codes and standards. This makes compliance straightforward no matter where the project is located.

ScotRF complements this ecosystem by managing the direct link between design and production. Once a steel framing design is finalized, ScotRF communicates with the roll forming machine to fabricate components precisely as engineered. This direct line eliminates transcription errors, accelerates production, and ensures a true design-to-construction workflow for cold-formed steel projects.

Steel Framing with Scottsdale’s Roll Forming Machines

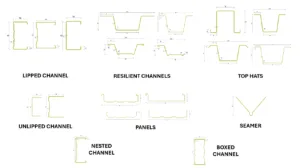

The heart of modern steel framing lies in the performance of the roll forming machine. Scottsdale’s roll forming technology fabricates nearly 100 different profiles of cold-formed steel, from standard SFIA profiles to custom Scottsdale shapes. These machines are engineered to integrate directly with our software ecosystem, meaning every stud, track, truss chord, or panel is manufactured exactly as designed.

Our customers use this combination of roll forming steel framing and software-driven accuracy to build residential, commercial, industrial, and modular structures faster and more cost-effectively than ever before. Whether it’s wall panels, cold-formed steel trusses, or complex framing assemblies, the roll forming machine’s precision ensures a seamless fit and superior strength.

Project Highlight

Institutional Cold-Formed Steel Framing Project

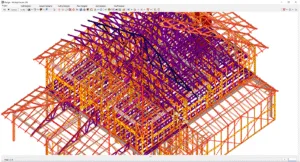

In the heart of Harris Town, Toowoomba, Queensland, Australia, an impressive institutional construction project, Concordia College, has been brought to life using advanced cold-formed steel framing by our customer TAG Frames. The project required 26,150 kilograms of precision-engineered cold-formed steel framing, integrated seamlessly with structural steel framing to deliver strength and efficiency.

Thanks to Scottsdale’s powerful software packages, combined with third-party design tools, all detailing was completed in just four weeks, showcasing the speed and accuracy of modern steel framing design. Fabrication of the entire cold-formed steel members took only two weeks and was produced using three advanced Scottsdale roll forming machines, including two Scotpanel 7090 roll forming machines and one Scottruss 6050 roll forming machine, demonstrating the unmatched capability of roll forming steel framing technology to accelerate large-scale construction projects.

Learn more about the design and fabrication process of Concordia College by reading “Remarkable Results in Steel Framing with Roll Forming Technology”.

Unified Steel Framing Design and Roll Forming Workflow

One of the greatest challenges in building design has been managing separate systems for design, engineering, and fabrication. Scottsdale eliminates this barrier by offering a unified platform where every stage of cold-formed steel design communicates effortlessly. This end-to-end workflow reduces manual input, minimizes human error, and accelerates project delivery.

The integration also provides flexibility. While Scottsdale software is fully optimized for our roll forming machines, it can also integrate with third-party design or production platforms, ensuring customers retain freedom of choice while enjoying the efficiencies of a complete ecosystem.

Cold-Formed Steel Standards and Global Compliance

Every aspect of Scottsdale’s cold-formed steel design software and steel framing systems is built around international codes and standards. From the IBC and IRC in the United States to AS/NZS 4600 in Australia and Eurocode 3 across Europe, our technology ensures compliance across global markets. Furthermore, Scottsdale maintains ICC-ES approvals and aligns with SFIA standards, giving builders confidence in code-compliant performance.

Training, Support, and Customer Success in Steel Framing

Investing in Scottsdale’s technology is more than acquiring a roll forming machine. Customers receive private training on hardware and software, plus unlimited 24/7 global support. Because our experts understand both steel framing design and the roll forming machines that fabricate members, issues are resolved quickly and comprehensively. This holistic support ensures that every project, whether it’s modular housing, commercial steel framing, or large-scale infrastructure, runs smoothly from design to delivery.

A Smarter Future for Roll Forming Steel Framing

The future of construction lies in the intelligent combination of cold-formed steel material, steel framing design, and advanced roll forming machines. Scottsdale’s integrated ecosystem of ScotSteel, ScotStruct, and ScotRF redefines how builders approach cold-formed steel design, delivering unmatched accuracy, speed, and efficiency.

From concept to completion, our system ensures that every steel framing member, panel, and truss is engineered, analyzed, and fabricated with precision. By unifying design and production, Scottsdale empowers builders to deliver stronger structures, faster timelines, and more profitable projects, all powered by the seamless integration of software and roll forming steel framing technology.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Cold-Formed Steel Framing Using ScotSteel with Ease

- Blog – Best Steel Framing Detailing Advice to Incorporate in Your Design

- Blog – Strengthening of Hat Section Trusses Under Heavy Loads

- Blog – How to Empower Steel Framing Startups Through New Software

- Video – How Scottsdale’s Roll Forming Technology and Software Support Business Growth

- Video – Producing Steel Framing Designed with Revit, ScotSteel, and Strucsoft MWF

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.