Steel framing success isn’t just built on rollforming machines and raw materials—it hinges on the software that brings it all together. Scottsdale’s latest software release is a game-changer for the industry, especially for new entrants looking to maximize efficiency and profitability from day one. Designed with startup operators in mind, this powerful upgrade delivers broad-based savings and performance gains through three standout features:

-

Integrated structural engineering analysis

-

Automated printed fabrication layouts

-

Truss engineering self-certification tool

This release streamlines design, compliance, and production—making it easier than ever to scale a steel framing operation with confidence.

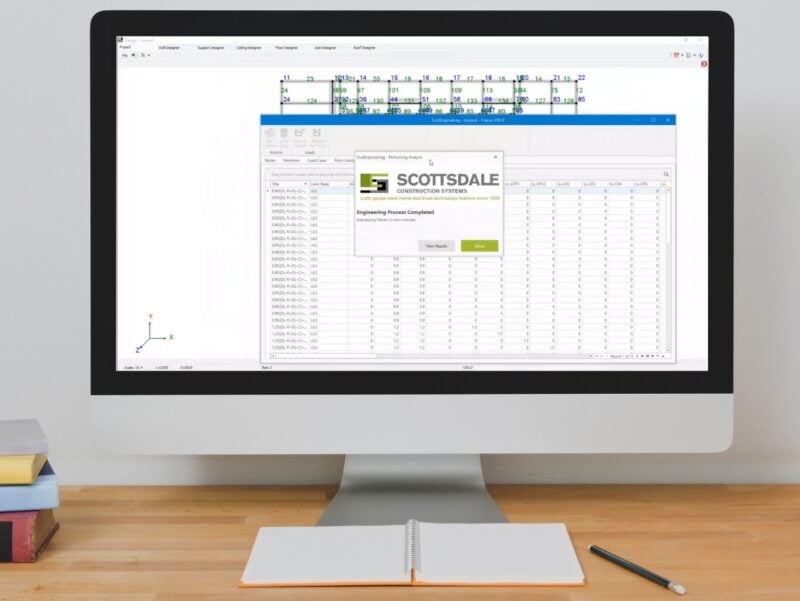

Integrated Structural Engineering Analysis

With the added structural engineering analysis, designers can perform advanced Finite Element Analysis on each panel/truss within seconds. Structural Engineering Analysis is a new, interactive feature that allows you to choose any frame in a design, define the loads and load combinations that apply to nodes and members and run the analysis on that frame, all within the Scottsdale Software.

Previously, performing structural analysis would have required manual translation of the design geometry to an engineering model (with nodes and elements) using third-party software, which was a laborious task. Designers then had to define loads within the software to enable the analysis that obtains displacements, forces, and moments.

Scottsdale’s latest engineering software development provides advanced finite element analysis (FEA) methodology on a panel or truss within seconds with just one click. It outputs the automated analysis to a spreadsheet for easy review of final results. This allows member/design checking against the performance requirements.

Within the program, designers can simply:

- Select and display a frame

- Review nodes and members

- Configure support/boundary/restraint conditions

- Define loads and load combinations

- Select ‘Run Analysis’ to view results

The Structural Engineering Analysis feature is globally consistent, and it is not subject to regional or national differences. This makes the analysis feature available to engineering operations of all Scottsdale Construction Systems customers and saves on engineering time, cost, and reduces the risk of errors.

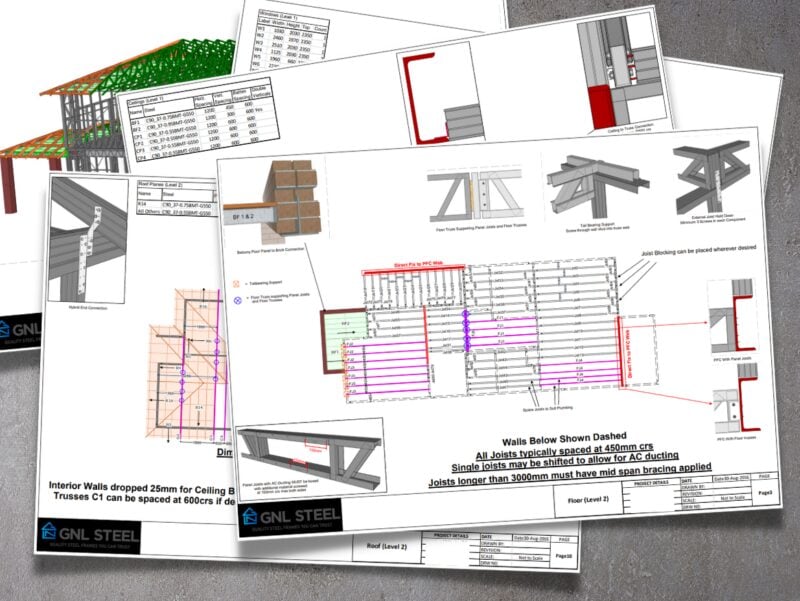

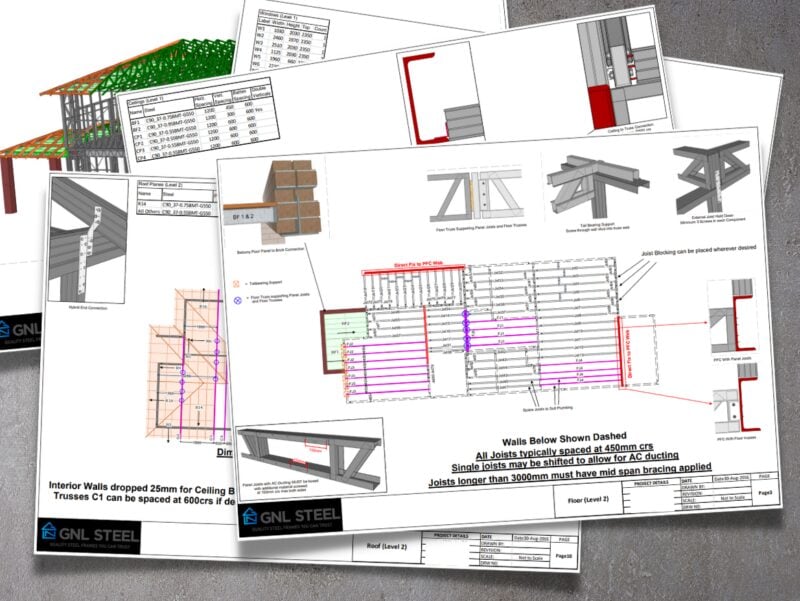

Automated Printed Fabrication Layouts

With the automated printed fabrication layouts, our customers can improve floor staff efficiency during fabrication and assembly. Previously, within the ScotSteel design software, designers could choose to print frame details for the selected frame or groups of frames. This functionality would provide a basic PDF printout with marking dimensions exterior to the drawing but only specifically listing the perimeter items.

With the new Fabrication Printouts, these basic PDFs have been replaced with a more detailed version. The new fabrication printouts are designed to make fabrication easier for the floor staff by numbering every fabricated item on the drawing and listing details including optimal order of assembly. The printouts come directly and solely from the design software and provide all the required information. This new feature is fully integrated with the information selected, including:

- Frame name

- Profile type, gauge, and tensile strength

- Item orientation (left, right, up, down)

- Production order numbering and lengths of each item

- Table to add bracing details

- Option to add customized company logo

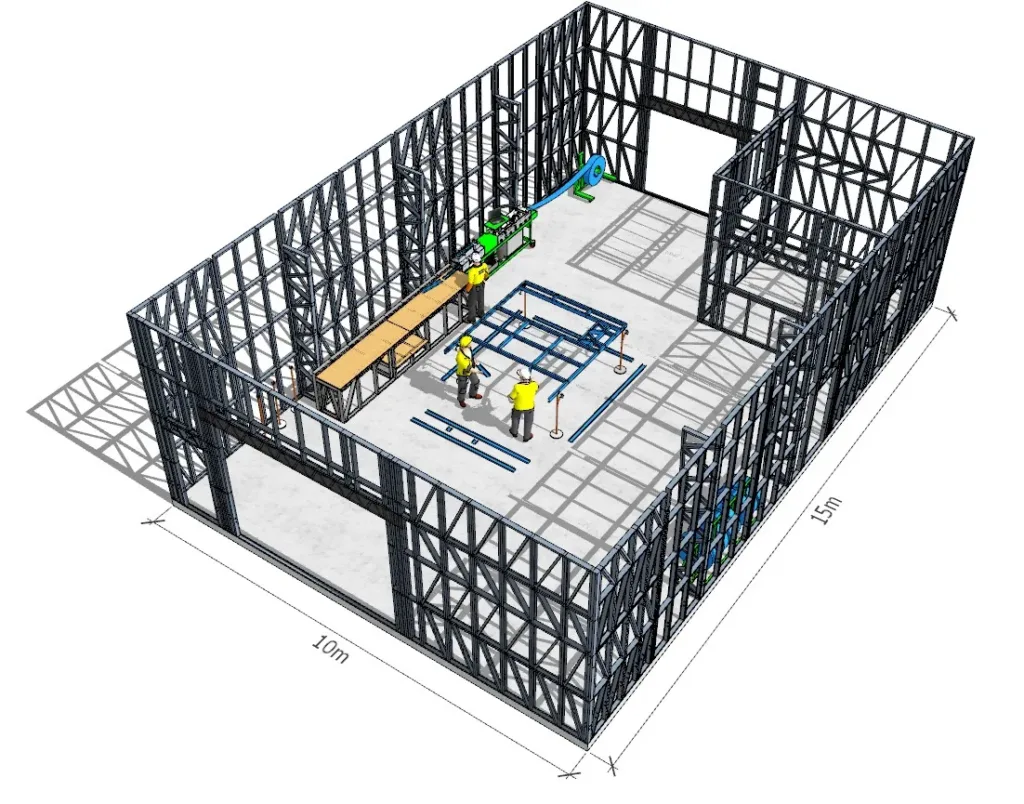

The printouts for each steel frame can then be used for assembling whether in the factory or when flat packed for onsite delivery, as shown below.

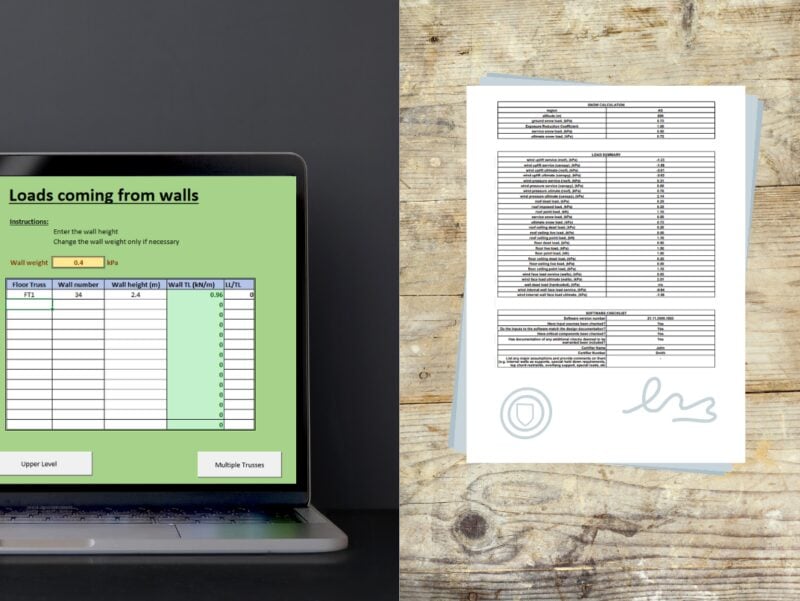

Truss Engineering Self-Certification Tool (AUSTRALIA ONLY)

Designers can now leverage our new self-certification feature for steel truss engineering, bringing greater efficiency and independence to the design process. While self-certification has long been available for timber trusses in Australia, we recognized the need to provide the same capability for steel. Our team of developers have successfully upgraded the software to support this functionality, automating key engineering checks to streamline approvals and reduce costs. This advancement is a game-changer for builders and fabricators embracing steel framing whether as a primary solution or a flexible alternative driven by market conditions, project requirements, or client preference.

When to use the Truss Engineering Self-Certification feature?

We’ve maintained flexibility in the process by allowing designers to choose whether or not to use the Self-Certification feature based on their specific project needs and capabilities. This selection is made during the setup of the Engineering Environment in our ScotSteel design software, where users are prompted to choose between “Non-Self-Certification” and “Self-Certification” modes.

When operating in Self-Certification mode, users can input project-specific variables such as roof material, wind region, snow region, and site altitude. The system then automatically calculates the relevant loads and checks for any limitations, such as maximum building length, that may require a professional engineer’s review. These parameters are built into our software to help designers make informed decisions.

In essence, this means users would only need a detailer and certifier and not a structural engineer—for qualifying projects. Scottsdale Construction Systems provides training and competency assessments for your design team, after which a certification number is issued to enable use of the system including certification of drawings. The software then generates a truss Self-Certification PDF ready for submission.

Truss Engineering Self-Certification feature outside of Australia

If you’re operating outside of Australia, please let us know when self-certification becomes permitted by your local regulators. Our team of developers can then assess and implement the necessary software updates to align with your country’s building and design codes.

These three major upgrades are just the beginning. As part of our ongoing commitment to strengthening in-house software capabilities and enhancing user experience, we’ve also introduced several additional improvements and resolved a number of bugs in this release.

Training and Operational Support

Scottsdale Construction Systems is here to support you every step of the way. We’re not just rolling out powerful, cost-saving innovations through our software team, but we’re also committed to helping our customers unlock their full potential. That means more than just training your design, detailing, and engineering teams or contractors. We also assist in identifying and onboarding the right talent to build your capability from day one.

At Scottsdale Construction Systems, we understand steel framing and the codes and standards behind it. Our expertise in business setup and operations is unmatched, and we’re passionate about helping our new customers succeed. Your success drives ours and we make sure you’re equipped to hit the ground running.

Contact us to find out more about our groundbreaking cold-formed steel design software, robust roll forming machines, 24/7 support, and unique business setup and operational know-how.

Contact us to find out more about our groundbreaking cold-formed steel design software, robust roll forming machines, 24/7 support, and unique business setup and operational know-how.