In the heart of Harris Town, Toowoomba, Queensland, Australia, a remarkable institutional construction project has taken shape with light-gauge steel framing — Concordia College. Completed by TAG Frames for a valued returning client, this 1,975 square meter steel framing project demonstrates what’s possible when expert detailing, powerful roll forming machines, and light-gauge steel material come together.

This project stands out not only for its scale but for its precision and the seamless coordination that defined every stage of design and construction. It is a testament to the future of light-gauge steel construction.

Steel Framing Scope and Project Materials

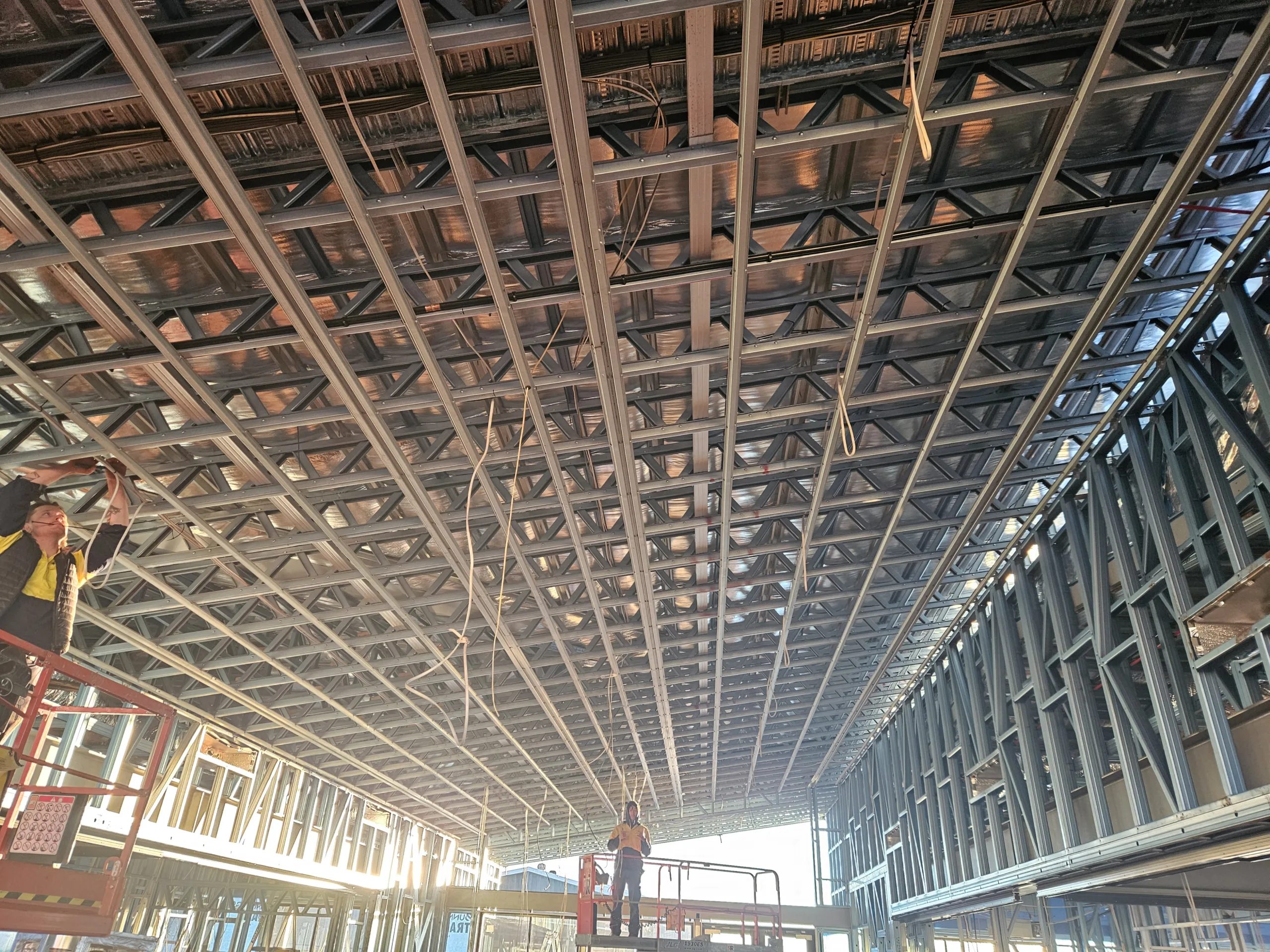

At the core of the Concordia College building is an impressive volume of 24,146 meters of light-gauge steel framing. This includes:

- 15,873 meters of light-gauge steel wall frames

- 8,273 meters of light-gauge steel roof trusses

To fabricate the structure, TAG Frames used 26,150 kilograms of light-gauge steel, highlighting the material efficiency and strength of steel framing solutions in institutional projects. This extensive steel package was a blend of both light-gauge steel and structural steel, showing how hybrid systems can deliver performance and design flexibility.

Combining Structural Steel and Light-Gauge Steel

While light-gauge steel carried the primary framing load, the project also incorporated key structural steel elements. Most notable among them are:

- 530 mm universal steel beams, adding rigidity and strength to critical load-bearing zones.

- 300 x 200 RHS Y-shaped steel columns in the pop-up roof section, adding architectural flair while supporting structural demands.

- Multiple light-gauge steel lateral force resisting systems, including K-bracing and strap bracing, provide stability against wind and seismic forces.

This combination of detailing and engineering finesse makes Concordia College a benchmark for mixed material framing in this institutional construction project.

Speed and Precision with Roll Forming Steel Framing Machines

Time was of the essence, and TAG Frames delivered. The entire detailing package, including both light-gauge steel and structural steel, was completed in just four weeks. That includes full roll files and fabrication drawings, done entirely in-house by TAG Frames.

From there, production moved quickly. Using three advanced Scottsdale roll forming machines — two Scotpanel 7090s and one Scottruss 6050 — TAG Frames completed the roll forming process of 24,146 meters of light-gauge steel framing in just two weeks.

This speed showcases the capability of Scottsdale’s roll forming machines and underscores the advantage of bundling Scotpanel and Scottruss machines to deliver complete steel framing solutions. Explore how this combination of Scotpanel and Scottruss roll forming machines can transform businesses.

Seamless Execution with Light-Gauge Steel and Software Integration

What’s most impressive about this project is not just the scope and speed, it’s the flawless coordination. According to TAG Frames, there was zero communication required between project stakeholders regarding design issues or fabrication problems during the project construction.

This level of precision and performance reflects the synergy between TAG Frames’ expertise and Scottsdale Construction Systems’ ecosystem of hardware and software tools. It’s a success story born from mutual commitment to quality, accuracy, and continuous strive for excellence.

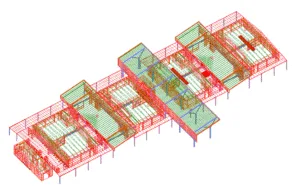

A Deeper Look into the Light-Gauge Steel Framing Model

For those wanting to explore the project further, the Concordia College steel framing model is available to view. More innovative light-gauge steel projects can be accessed, showcasing a wide range of applications in residential, modular, commercial, and institutional sectors. Each project reflects how roll forming steel framing is reshaping what’s possible in construction, bringing speed, precision, and scalability to builders around the world.

Building with Steel Framing in 2025

In today’s fast-paced construction environment, projects like Concordia College prove a critical point: construction doesn’t have to be slow, complicated, or error-prone. With the right team, tools, and materials, such as light-gauge steel and advanced roll forming technology, ambitious institutional builds can be delivered faster, smarter, and better than ever.

From the clean transitions between steel systems to the crisp Y-columns and concealed lateral bracing, every detail of this project speaks to what’s possible when roll forming machines are leveraged to their full potential. TAG Frames’ attention to detail, combined with their trust in Scottsdale’s roll forming systems, continues to raise the bar for light-gauge steel construction in Australia and beyond.

Light-Gauge Steel Construction Powered by TAG Frames

To give deeper insight into the people and processes of a steel framing fabrication business, we recently visited TAG Frames’ facility in Queensland for an exclusive interview. Watch the full three-part series below:

These interviews explore how TAG Frames combines smart design, capable people, and powerful roll forming equipment to deliver steel framing solutions at scale.

At Scottsdale Construction Systems, we’re proud to support industry leaders like TAG Frames. Their success is our success, and Concordia College is a perfect example of what’s achievable when high-performance roll forming machines, light-gauge steel, capable teams, and smart workflows all come together.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Design Inexpensive Cold-Formed Steel Commercial Buildings the Right Way

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Blog – How to Achieve Better Spans with Cold-Formed Steel Trusses

- Blog – Comparing Steel vs Wood Framing: Why Steel is Better

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.