In light-gauge steel framing, detailers must take a comprehensive view of connection design to ensure structural integrity, efficient load transfer, and constructability. One fundamental connection type often used in steel framing systems is the seated connection. These connections, when properly applied, enhance the performance of both steel trusses and framing assemblies. This article explores the role of light-gauge steel seated connections, their benefits, design considerations, and practical applications in modern roll forming construction.

What Are Seated Connections

A seated connection is a type of beam-to-column connection where the beam rests on a horizontal support, typically a seat angle or seat plate, secured to a vertical member such as a column, wall stud, or jack stud. In steel framing systems, this connection type is commonly used to support vertical loads, providing a physical bearing seat beneath the beam’s bottom flange.

In light-gauge steel framing, where members are roll-formed from thin steel sheets, seated connections are critical in transferring loads safely without over-reliance on fasteners alone. These connections ensure that compression forces are adequately supported through direct bearing rather than tension-only methods, which can compromise structural performance.

Advantages Of Light-Gauge Steel Seated Connections

Seated connections offer several benefits in steel framing design, particularly for light-to-moderate-load applications:

- Simplicity and speed: Their straightforward layout makes seated connections easy to fabricate and install, especially in off-site prefabrication environments using roll forming machines.

- Rotational flexibility: They allow limited rotation, accommodating structural movements and minimizing stress concentrations in simple framing systems.

- Economy: Seated connections use fewer materials and require less labor, making them cost-effective for light-gauge steel framing applications.

- Improved load path: These connections provide a direct and efficient load transfer path, reducing reliance on rivets or screws in compression-critical areas.

Design of Light-Gauge Steel Seated Connections

A “seated connection” typically relies on a horizontal component, seat angle or plate, fashioned from light-gauge steel that directly supports the end of a beam. In light-gauge applications, this usually consists of a bent steel member mechanically fastened, with screws or bolts, to the column or wall stud, and then the supported beam is likewise fastened to the seat. The selection of fasteners and pattern, as well as the seat thickness and width, must match both the load demands and the properties of the light-gauge steel material used.

In light-gauge steel systems, seated connections must be carefully detailed to maintain full-profile engagement wherever possible, especially since light-gauge steel framing members may have lips, flanges, and punch-outs that affect performance.

Code Compliance and Construction of Seated Connections

All light-gauge steel components must conform to applicable material standards for structural sheet, as outlined in the building code. The connection must be detailed to ensure that the member and fastener capacity, as well as the bearing at the seat, are adequate. Sharp bends or excessive cold-work at the seat area should be avoided by respecting minimum bend radii, thus maintaining expected performance under loads.

In gravity framing with light-gauge steel, seated connections are common and are not usually expected to resist significant seismic forces. If a connection is intended for inclusion in a lateral (seismic) force-resisting system, further analysis could be required.

It is important to avoid abrupt notching, sharp corners, or field modifications that could induce unanticipated stress concentrations or weaken the connection area. Employ correct screw or bolt types as specified for light-gauge steel and verify installation torque or seating to avoid overdriving or stripping threads in thin material.

For the design of cold-formed steel members, refer to the codes and standards listed below:

AISI S100 – North American Specification for the Design of Cold-Formed Steel Structural Members

AISI S100-16 (2020), Chapter J, addresses cold-formed steel-to-steel Connections and Joints.

AISI S202 – Code of Standard Practice for Cold-Formed Steel Structural Framing

AISI S220 – North American Standard for Cold-Formed Steel Nonstructural Framing

AISI S240 – North American Standard for Cold-Formed Steel Structural Framing

Scottsdale Construction Systems’ advanced software, ScotSteel and ScotStruct, follow the AISI standards, making the design and engineering of cold-formed steel sections and the structural analysis of cold-formed steel structures as easy as possible. Although engineering judgment is always required to verify the designs and details, especially for members under combined loading.

When To Use Light-Gauge Steel Seated Connections

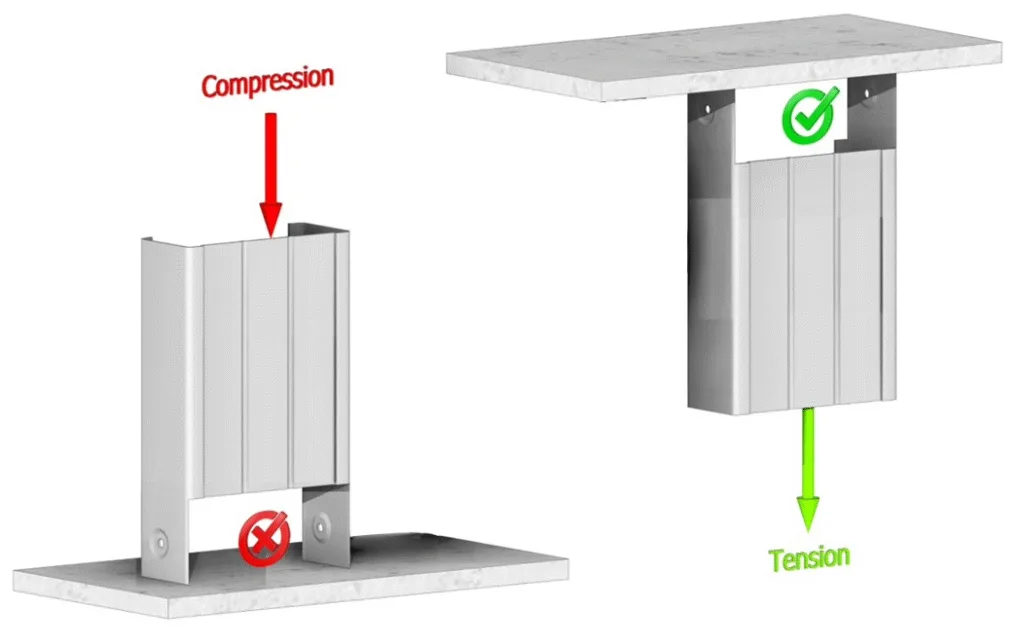

Light-gauge steel framing detailers need to understand the difference between compression and tension members while understanding load distribution. Not always is the software’s solution to place a rivet/screw at the location of the connection is enough.

Seated connections are particularly important for load-bearing members, K-Bracing, Box Gutters, Roof Valley Trusses, Stepdown Floor Trusses, Lintel Jack Studs at each end of a lintel, and Jack Studs taking point load from above, i.e., Truss.

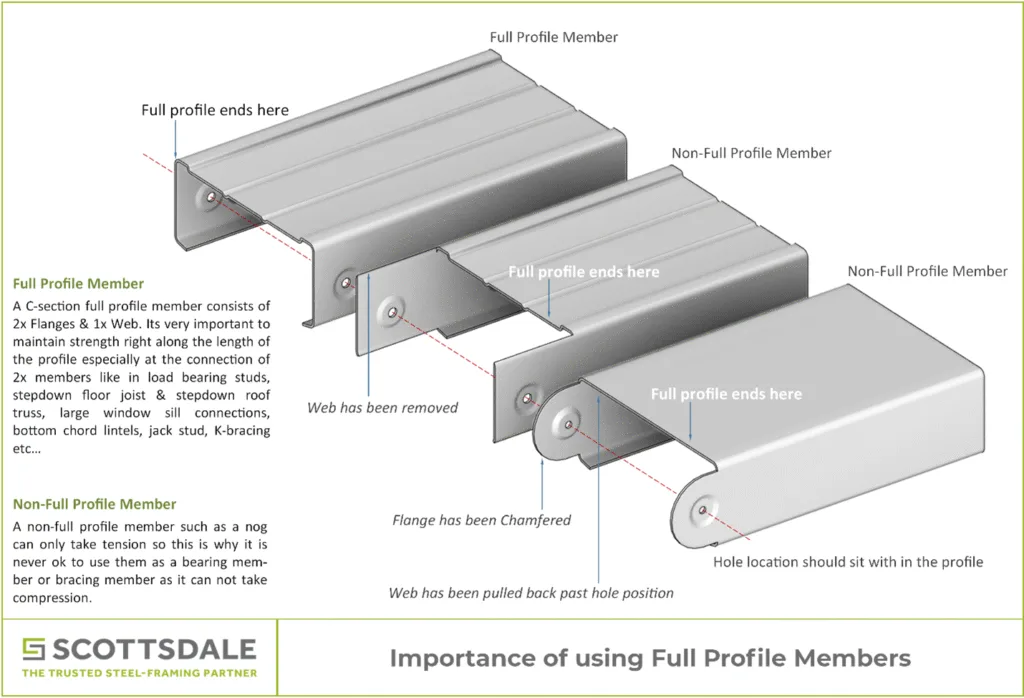

It is important to emphasize the use of a full-profile member in light-gauge steel seated connections under compression loading to ensure proper load transfer and structural performance.

Example #1

Seated Connections in Trusses

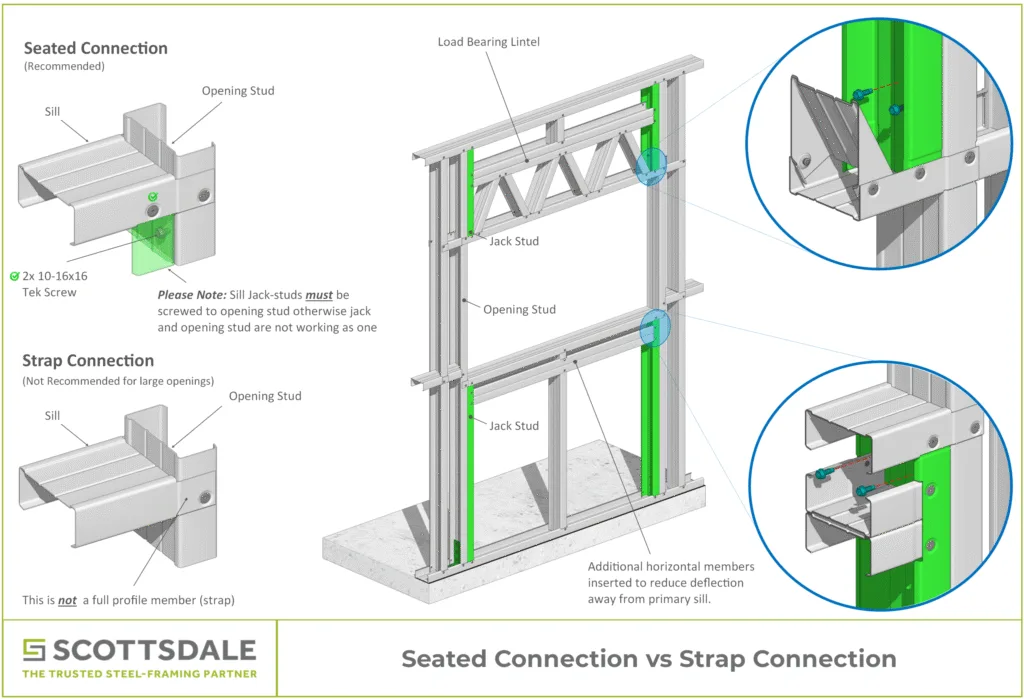

All lintels that require jack studs to be aligned directly under trusses need a double top chord when under load. A single lintel will have non-seated jack studs, whereas a double top chord lintel will have properly formed jack studs and is the same for support frames. Why? It’s because the bottom connection of the jack stud to the top chord is only a strap connection. After all, it’s not a full-profile member since the notch punch has removed the web. Another way to look at this connection is as a non-seated connection. It’s good in tension but useless in compression.

Another way for others to understand this would be to ask them to perform a “hand test” by just using their fingertips. Generally, fingers are better in tension (pulling) rather than compression (pushing). Similarly, this is the same with a non-full-profile-member that has the web removed and is only relying on the flanges to support the loads it is carrying.

Another way for others to understand this would be to ask them to perform a “hand test” by just using their fingertips. Generally, fingers are better in tension (pulling) rather than compression (pushing). Similarly, this is the same with a non-full-profile-member that has the web removed and is only relying on the flanges to support the loads it is carrying.

Example #2

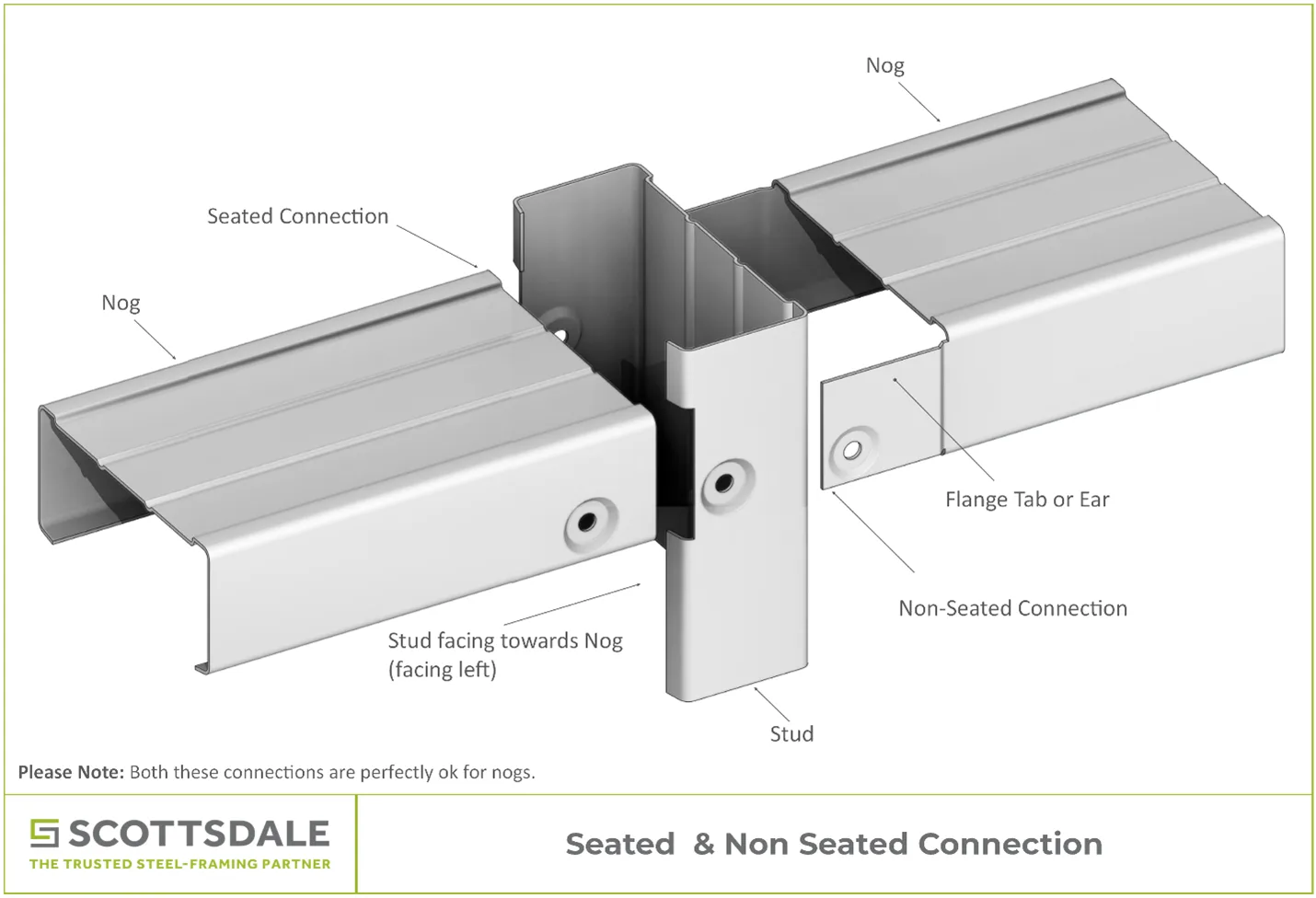

Seated Connections in Facing Studs

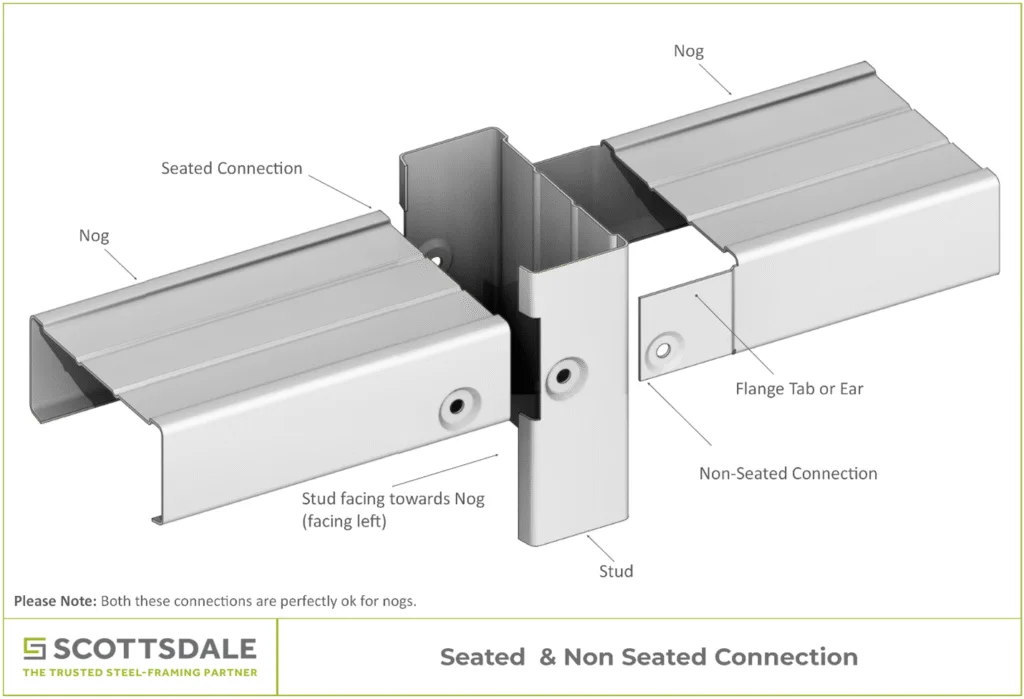

C-section member can be oriented facing or facing away (Up/Down, Left/Right). A facing member is the strongest connection as this creates a seated connection while maintaining 100% of both members’ profiles.

Whereas a member connected to a facing away member will have to flatten the lips and notch out its web so the flanges can go around either side of the facing away member. This can be called a strap connection as the flanges have no real strength other than tension when it is tensioned in the direction of the pull. These straps are also subjected to other forces other than the direction of the pull. Please see the image of a seated connection in facing studs and a non-seated connection below.

Example #3

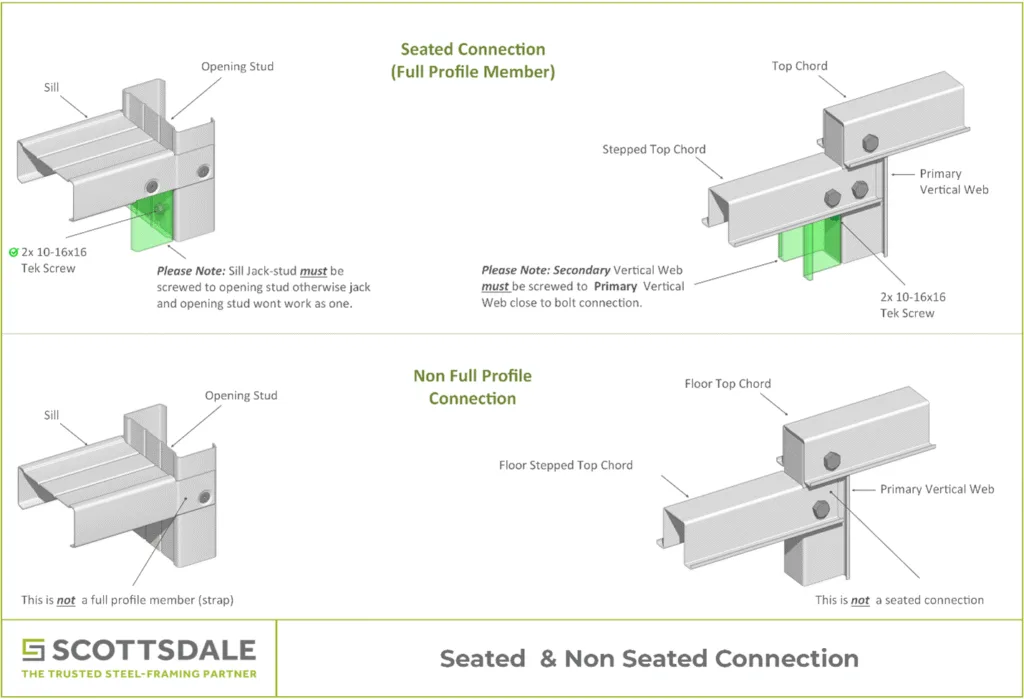

Seated Connections in Step-Down Floor Joists

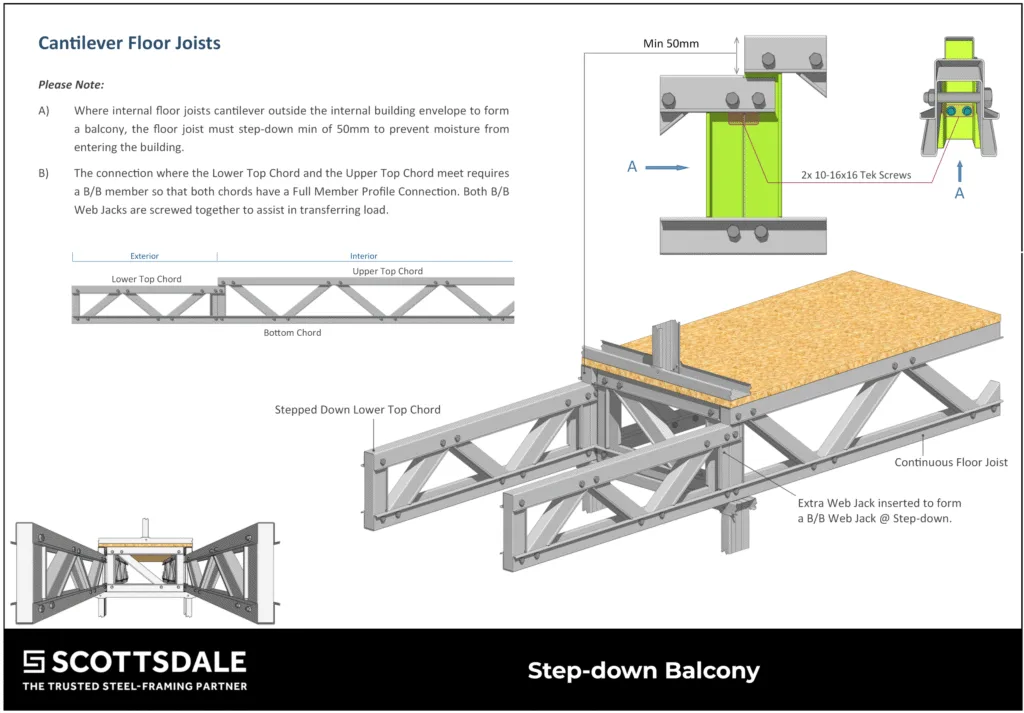

Floor joists are another important area where you have a step-down floor. The ScotSteel software will place one vertical member where the stepdown occurs, but it’s up to the detailer to place a secondary member to avoid leaving the connection as an unseated connection. When you need to add a secondary member to strengthen a primary member, it changes the connection from a non-seated to a seated connection.

This, on its own, is still not enough. You still need to Tek screw both primary and secondary members together otherwise the connection is still compromised. The Tek screws will transfer load and make both members work as one. Please see the image below detailing a step-down balcony.

Key Takeaways For Light-Gauge Steel Seated Connections

As light-gauge steel framing continues to grow in popularity across commercial, residential, and modular construction, understanding how to design and apply seated connections becomes increasingly important. With roll forming machines delivering precise, consistent profiles and detailing software automating many tasks, it’s still up to the detailer and engineer to ensure proper connection design, especially where compression is involved.

Seated connections help preserve the integrity of light-gauge steel design by ensuring that loads are carried safely and effectively through direct bearing rather than over-reliance on fasteners. Whether you’re detailing a floor system, steel trusses, or wall panel framing, integrating seated connections into your steel framing design will improve long-term structural performance and construction efficiency.

Scottsdale Construction Systems’ support team can help in the design process of light-gauge steel seated connections and more. Learn more about our roll forming technology, our state-of-the-art software, and our complete roll forming ecosystem by contacting us at sales@scottsdalesteelframes.com or calling us at +1 (888) 406-2080.