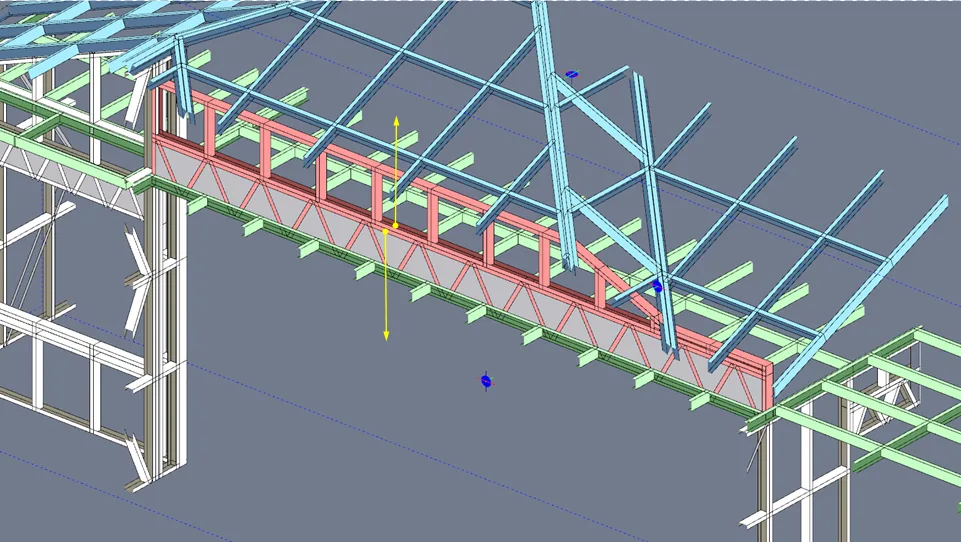

In the world of structural engineering, even small design oversights can impact structural performance. In steel framing design, one recurring issue involves the design and fabrication of a double top chord lintel, a critical component in load-bearing walls. While software tools, experienced detailers, and engineers support the process, effective cold-formed steel design requires more than just automation. It demands attention to details, especially in lintel design, where connection methods and plating dimensions determine whether a frame will structurally perform as intended.

What is a Lintel in Steel Framing

A lintel is a horizontal support element placed above openings like doors and windows. In steel framing, a lintel acts as a beam that transfers loads around a void to adjacent framing members. Whether architectural or structural, it supports both gravity and uplift forces. Using cold-formed steel, a properly designed lintel can be strong, lightweight, and efficient in performance, especially when fabricated using advanced roll forming equipment for consistent, precise output.

The Purpose of a Double Top Chord Lintel

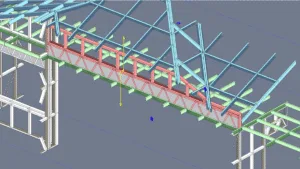

A double top chord lintel strengthens the lintel’s top chord to better align with jack studs and resist uplift. It enables direct truss alignment above openings and provides a fully seated connection for the jack studs. In cold-formed steel design, this approach increases capacity and stiffness without significantly adding weight, making it ideal for high-performance steel framing.

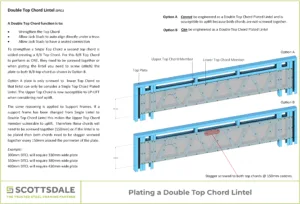

The double chord is formed by attaching a second steel member back-to-back (B/B) with the original top chord. This pairing only functions properly if the two are screwed together or tied by a full-width plate that connects both chords.

Common Mistakes in Cold-Formed Steel Lintel Design

A major flaw in lintel design occurs when the double top chord members are not adequately connected. When crews neglect to stitch the chords together or use incorrectly sized plates in the field, this results in a critical failure. In these cases, when the frame is lifted, the chords separate, revealing a visible gap and indicating that the double top chord lintel is not acting as a unit.

This problem is compounded when jack studs are connected only to the upper chord, which isn’t engaged with the lower. This creates a disconnect in the load path, compromising the strength and performance of the cold-formed steel lintel.

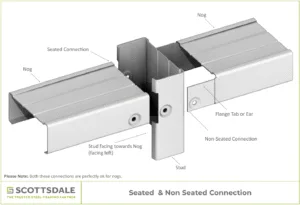

It’s important to note the double-end jack studs that allow the bottom chords to be fully seated connections and transfer loads. Without the double-end jack studs, the connections will only be a strap connection and could possibly tear at those locations. Refer to our blog on “Everything You Need to Know About Light-Gauge Steel Seated Connections” for more information on how to properly connect steel framing members.

Best Design Practices for Cold-Formed Steel Double Top Chord Lintel

For a double top chord lintel to act as a single unit in steel framing, proper detailing is non-negotiable. Here are key principles for properly designing a cold-formed steel double top chord lintel.

- Stitching: The upper and lower top chords must be screwed together, making a back-to-back (B/B) connection. This ensures they behave as one structural element.

- Plating: If using a plate instead of direct screw connections, it must span the full width from the bottom of the lintel to the top of the upper top chord. This is critical for load transfer.

- Screw Placement: When using a plate, screws should be staggered around the perimeter, engaging both chords, to provide uplift resistance. Screwing the plate to only the lower chord means the lintel will only engage with the single chord.

- Support Frames: If a wall is upgraded from a single lintel to a double top chord lintel, verify that the top chord is not floating and both members are engaged. Any cold-formed steel member not tied in can be subject to uplift and movement.

These practices are particularly relevant in projects using roll forming technology, where steel components are fabricated in high volumes. Without proper detailing, even perfectly shaped components may fail under load due to missed connections.

Scottsdale Construction Systems has a large library of cold-formed steel detailing documents and roll forming documents available on our KnowledgeBase platform.

For more cold-formed steel design insights visit us at https://knowledge.scottsdalesteelframes.com/.

The Role of Roll Forming in Steel Framing Design

Roll forming is a manufacturing process that transforms flat steel coil into engineered components for steel framing. When used to fabricate cold-formed steel lintels, the precision of roll forming enables consistent geometry, but the connections and plating are still dependent on design and assembly.

That’s why understanding cold-formed steel design principles is vital. There are many advantages of roll forming, but poor design or misaligned components can negate those benefits. This is especially true for high-performance elements like a double top chord lintel, where connection quality drives load transfer efficiency.

Final Thoughts on Double Top Chord Lintel Performance

The strength of a double top chord lintel depends on its ability to act as a single, unified component. Without proper stitching or plating, the upper chord becomes redundant, leaving the lower chord to bear all structural loads. This violates basic cold-formed steel design principles and weakens the overall frame. To achieve consistent, safe, and high-performing steel framing, every detail of the lintel design must be validated, from the plate width to the screw spacing. This ensures the full benefits of cold-formed steel and roll forming can be realized in the final structure.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Blog – Practical Guide to Web Openings in Cold-Formed Steel Framing

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Blog – New Solution for Fascia Bracket Installation in Cold-Formed Steel

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Blog – Unlocking New Potentials with Cold-Formed Steel and Roll Forming

- Blog – Steel Framing: A Powerful Response to Thermodynamic Challenges

- Videos – Welcome to Scottsdale: Discover Our Entire Ecosystem

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.