Modern construction increasingly demands materials that perform under pressure, whether from environmental extremes, economic uncertainty, or accelerated project timelines. In this context, cold-formed steel (CFS) has emerged as a front-runner for strength, speed, and sustainability. The use of CFS in the structural framing of buildings offers significant advantages, including durability, precision, and resistance to pests and fire. One of the limitations of cold-formed steel as a building material has been its thermal performance in cold climates, which has hindered its adoption in regions with harsh winters. Builders are overcoming this hurdle through a combination of advanced roll forming technology and innovative wall system design. These breakthroughs enable steel framing to meet stringent thermodynamic standards while preserving all the advantages of light-gauge steel construction.

The Problem: Thermal Conductivity in Cold-Formed Steel Construction

While cold-formed steel has become a popular material in modern construction for its strength, precision, and sustainability, thermal conductivity is a notable challenge. Steel naturally conducts heat, which can result in substantial energy loss in buildings located in cold climates. When temperatures drop below zero, buildings framed in steel may struggle with heat retention, leading to poor energy efficiency, discomfort, and higher heating costs.

This limitation has traditionally made CFS less favorable in regions with harsh winters. Without effective thermal barriers or insulation strategies, the benefits of light-gauge steel, such as fast construction, material consistency, and reduced labor needs, risk being overshadowed by performance issues related to temperature control.

The Solution: Thermally Efficient Double-Wall Steel Panel Systems

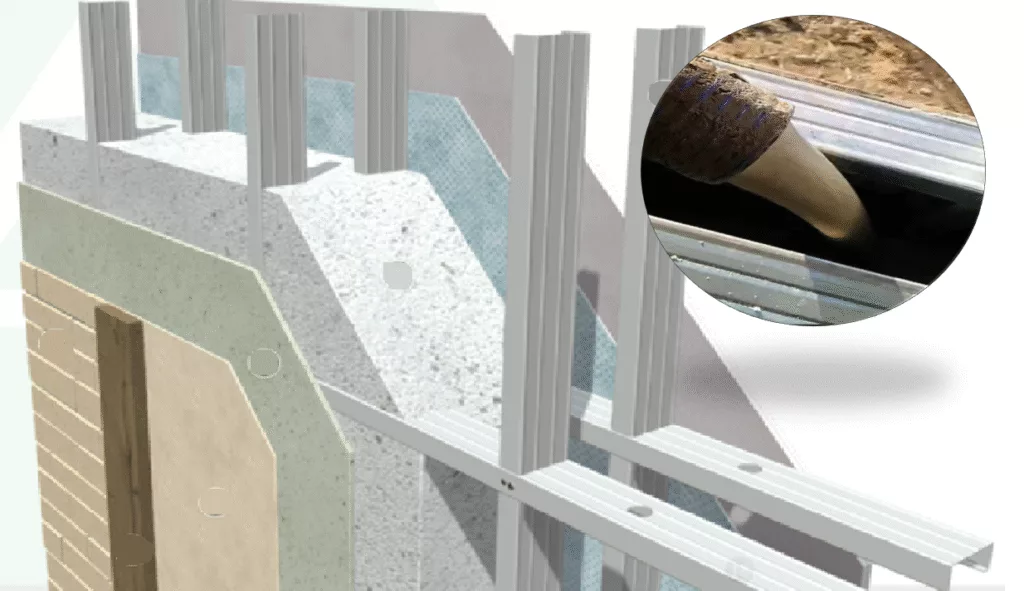

In response to these challenges, construction innovators and partners have developed a highly effective solution: a double-wall cold-formed steel panel system. Utilizing C-90 mm profiles produced via automated roll forming, this system features two steel-framed walls with a specially designed cavity in between. Scottsdale produces multiple roll-forming machine models capable of producing such shapes, including those within our Scotpanel, KFS Framemaker, and KFD Framemaker series.

The cavity is filled with lightweight, air-entrained concrete, which significantly enhances thermal insulation by limiting heat transfer through the steel. In addition to thermal performance, this infill material improves vibration resistance and adds mass to the wall structure, giving it strength characteristics closer to a solid monolithic system. The result is a building that is durable, energy-efficient, and climate-adaptive.

The double-wall cold-formed steel panel system design meets local thermodynamic standards while leveraging the speed, accuracy, and flexibility of steel framing. It’s a true fusion of traditional thermal principles and modern steel framing solutions.

Thermally Efficient Double-Wall Steel Panel Systems

Product Highlight

Scotpanel Roll Forming Machines

Our Scotpanel roll-forming machines produce precision-engineered C-section profiles, using roll formers such as Scotpanel 5090 and Scotpanel 7090, which serve as the core structural element of the thermally efficient double-wall cold-formed steel panel systems. These roll formers will produce framing members designed to enable advanced wall assemblies that enhance thermal performance, reduce thermal bridging, and support energy-efficient building designs. The integration of C-90 mm profiles ensures both structural integrity and compatibility with insulation strategies, making them ideal for high-performance construction across all building applications.

Advanced integrated roll forming technologies, such as the ones developed by Scottsdale, embodied in our Scotpanel and Scottruss series, greatly enable the production of such steel framing systems. This video provides a brief overview of our technology.

Steel Framing’s Proven Performance in Severe Climates

Our partners using this system across severe climates report exceptional results, both in thermal comfort and structural stability. They note that buildings go up faster, with greater accuracy and less waste. Scottsdale’s roll forming technology ensures each steel member is precision-cut and punched to design specifications, streamlining the fabrication and assembly process.

These structures have withstood not only temperature extremes but also other environmental challenges like seismic activity. Their thermal insulation reduces heating requirements, while their modularity and consistency provide significant cost and labor savings.

Global Potential and Expanding Innovation of Steel Framing

The success of these advanced steel wall systems demonstrates a clear opportunity for global application. Countries across Europe, North America, the Middle East, and Asia where cold weather or climate variability is a major concern, can benefit from adopting similar approaches.

By applying this thermally efficient cold-formed steel design, builders worldwide can unlock the full potential of steel framing without sacrificing energy performance. Whether in remote regions or urban environments, this solution is scalable and adaptable to a wide range of thermodynamic challenges.

Building Smarter with Scottsdale Roll Forming Solutions

At Scottsdale Construction Systems, we see this as a pivotal advancement in building innovation. The combination of cold-formed steel, precision roll forming, and strategic wall design positions steel framing not just as an alternative to traditional materials but as a leading solution for high-performance construction in challenging climates.

As global challenges demand smarter, more resilient structures, Scottsdale remains committed to delivering steel framing solutions that meet both structural and environmental standards. With continued innovation, cold-formed steel is helping shape the future.

We are proud to lead the way in roll forming technology and innovation, helping shape the future of the construction industry. Call us at 1 (888) 406-2080 or email us at rollformers@scottsdalesteelframes.info for more information on our state-of-the-art roll-forming machines and solutions.