In today’s construction landscape, steel framing and cold-formed steel have become the go-to solutions for building stronger, faster, and more efficiently. With the help of advanced roll forming technology, cold-formed steel components, ranging from studs and tracks to fully engineered cold-formed steel trusses, can be manufactured with precision and speed. This article answers the most commonly asked questions surrounding these systems, helping builders, architects, and manufacturers understand the core principles, benefits, and best practices. From choosing the right materials and machines to optimizing structural design and code compliance, this guide is your starting point for success in cold-formed steel construction.

Commonly Asked Questions

What is Cold-Formed Steel?

Cold-formed steel refers to steel that is shaped at room temperature, without the application of heat, using processes such as rolling, pressing, or stamping. Unlike hot-rolled steel, which is formed while the metal is molten or heated, cold forming increases strength and precision through strain hardening. Cold-formed steel is a foundational material in modern construction, especially when paired with roll forming machines that automate the production of precise steel framing components.

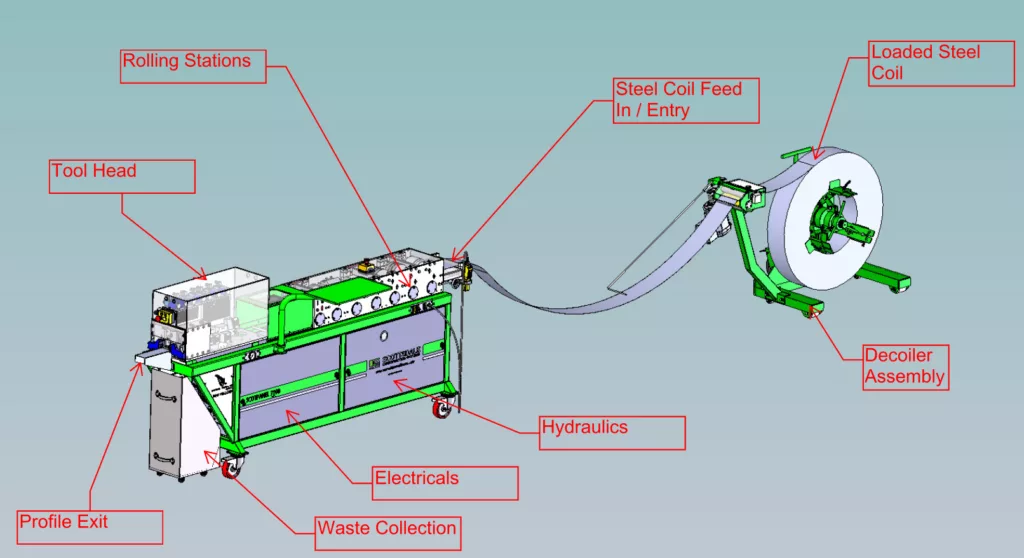

What is Roll Forming?

Roll forming is a continuous metal forming process used to shape sheet or strip metal into a desired cross-sectional profile by passing it through a series of precisely aligned rollers. Each roller set incrementally bends the metal until the final shape is achieved. Roll forming is especially favored in cold-formed steel construction for its speed, accuracy, and ability to integrate design and manufacturing workflows. Modern roll formers, such as those produced by Scottsdale Construction Systems, also incorporate advanced automations, including sophisticated software integrations, which allow for a seamless nexus between design, engineering, and fabrication, all with great precision and efficiency.

When to choose Steel Framing?

Building with steel framing, particularly cold-formed steel, offers numerous advantages over traditional construction materials like wood or concrete. It combines strength, efficiency, and sustainability, making it a top choice for modern construction across residential, commercial, and industrial sectors. Steel framing provides a reliable, scalable solution for builders aiming to improve quality, efficiency, and sustainability without compromising design flexibility. Steel framing is especially well-suited for projects located in seismic zones, hurricane-prone regions, or areas at high risk of fire due to its superior structural performance and non-combustibility. Steel framing is also resistant to termites and offers far superior strength properties to wood at only a fraction of wood’s weight. Light weight of steel framing also makes it an ideal solution for panelized offsite construction and modular construction.

What are the benefits of Steel vs. Wood?

Steel framing offers several key advantages over wood framing, particularly in strength, longevity, safety, and sustainability. Steel framing advantages over wood include: strength, fire resistance, pest and mold resistance, durability, consistency in material, speed, efficiency, insurance savings, and more. A comparable steel frame or a wall panel also weighs far less than the wood alternative, which makes light-gauge steel framing ideally suited, and a far superior solution to wood, for offsite construction, panelizing, and modular construction.

How to design Cold-Formed Steel Buildings?

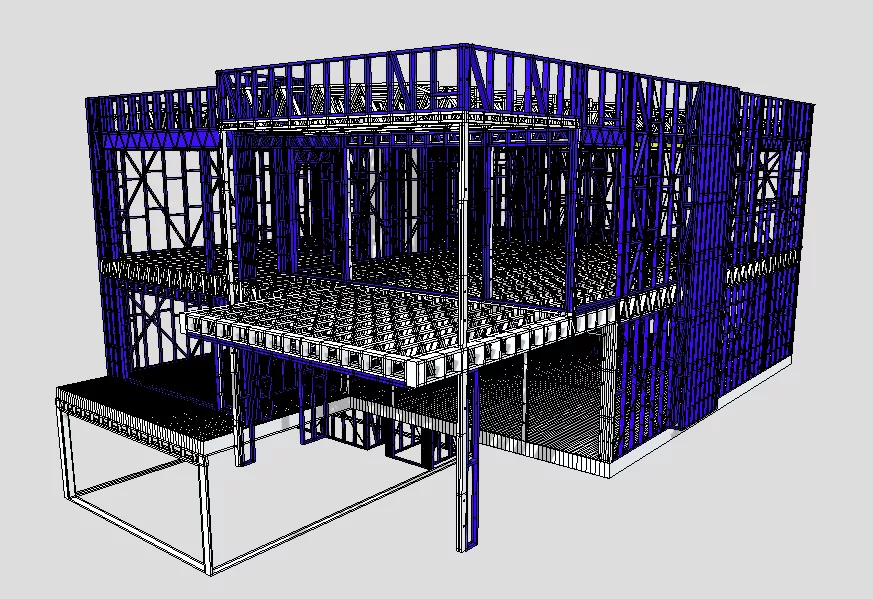

Designing a cold-formed steel building requires an integrated approach, combining structural analysis, software tools, and manufacturing processes. When done right, it leads to fast, precise, and cost-effective construction with high structural performance.

Design

Designing a cold-formed steel building begins with defining the project requirements, including the building type, structural loads, climate conditions, and relevant code requirements. The initial design of the building, framing layouts, openings, and architectural plans follow. The next step is choosing the appropriate steel framing, walls, floors, and roof systems, based on structural needs. Detailed 3D modeling of connectors, openings, and service penetrations for coordination with MEP is another crucial design step.

Engineering

Once these parameters are established, applicable standards such as AISI S100 (USA), CSA S136 (Canada), AS 4600 (Australia), EN 1993 Part 1-3 (European Union), and BS 5950 Part 5 (United Kingdom), depending on project location, are selected to guide the engineering process. Structural analysis and member design are then carried out using specialized software tools like ScotSteel, ScotStruct, Revit, or other design engineering platforms to ensure performance under loads. The final design is then reviewed for code compliance and submitted for engineering approval.

Fabrication

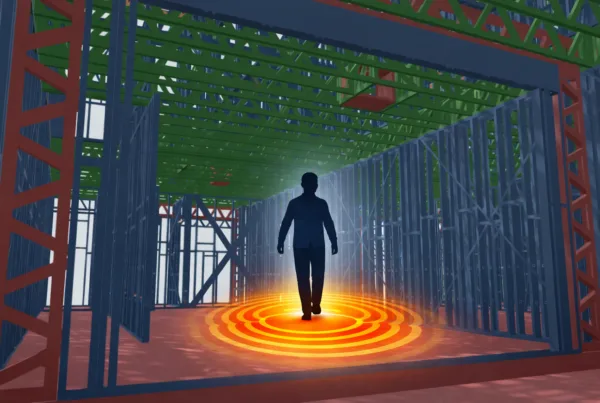

From the final models, production files are generated and exported to roll forming machines for manufacturing. Finally, all components are fabricated, either offsite or onsite, and assembled using rivets, screws, or bolted connections as specified in approved documents.

View Scottsdale’s full project gallery on Sketchfab.

What are Steel Trusses?

Steel trusses are structural frameworks composed of interconnected steel elements arranged in triangular configurations. This design efficiently distributes loads, providing strength and stability while minimizing material usage. Typically used to support roofs, floors, and steel trusses consist of top and bottom chords connected by web members, forming a rigid structure capable of spanning large distances without intermediate supports. Cold-formed steel trusses are designed following AISI S240 (USA), CSA S136 (Canada), AS 4600 (Australia), EN 1993 Eurocode 3 (European Union), and BS 5950 (United Kingdom), depending on project location.

Cold-formed steel trusses offer versatility in design, allowing for various roof shapes such as monoslope, dual pitch, scissor, and curved profiles. The adaptability and efficiency of cold-formed steel trusses make them a popular choice in modern construction projects, facilitating long spans, reducing construction time, and enhancing overall structural performance. Cold-formed steel trusses also facilitate easy placement of the MEP conduits within their depths, without the removal of cross section, as is the case with typical I-joists or C-joists, thus structurally weakening the framing members. Cold-formed steel trusses can be successfully deployed both in roofs and floors and offer far more flexibility to traditional joist framing in terms of shapes, spans, and performance.

How do I decide what Roll Forming Machine fits my needs?

Choosing the right roll forming machine depends on your production goals, project types, and operational setup.

When selecting a roll forming machine, consider your building application, whether you’re producing walls, roofs, floors, or prefabricated panels. Assess your profile requirements, including C and U sections, truss components, custom shapes, and specifications like web, flange, lip dimensions, and material thickness. Choose a brand that enables seamless data flow from modeling and engineering to production, leveraging integrated software to eliminate manual inputs, reduce errors, and streamline your entire process. Decide whether you need a single-profile or multi-profile machine. Ensure the machine integrates with your design process, supporting BIM workflows, CNC file compatibility, and direct control through your preferred software. Evaluate the machine’s mobility and footprint based on whether you operate onsite, in modular construction, or in a permanent factory. Budget beyond the machine’s purchase price by factoring in setup, training, software, support, material sourcing, and labor, prioritize lifecycle value and efficiency over upfront cost. Lastly, choose a manufacturer that offers strong post-sale support, including training, maintenance, spare parts, software integration, remote diagnostics, technical assistance, and engineering support.

Roll forming assemblies are quite complex and cannot be copied or easily reproduced. Decades of experience and engineering fine-tuning go a long way in assuring that a roll forming cage performs adequately over its intended range, and that all the auxiliary processes, such as cuts, punches, electronics, and software integrations, are properly configured. It is, therefore, important to choose a reputable manufacturer of roll forming equipment with a proven history and track record of delivering long-lasting, powerful, and sophisticated systems. It is advisable to always visit a framing factory deploying a particular roll former model and observe both roll forming machines in operation, as well as the quality of light-gauge steel framing it produces prior to purchasing a machine.

Scottsdale offers everything you need to get started. To explore the right roll forming solutions for your business, call us at 1 (888) 406-2080 or email us at rollformers@scottsdalesteelframes.info.