In the world of modern construction, cold-formed steel (CFS) framing has emerged as a powerhouse material, offering lightweight, high-strength solutions for residential, commercial, and industrial buildings. However, steel’s Achilles’ heel is corrosion—especially in environments exposed to moisture, salt, or pollutants. This is where galvanization steps in as a critical defense mechanism. Galvanization involves coating steel with zinc or zinc alloys to create a sacrificial barrier that protects the underlying metal from rust and degradation. Without adequate corrosion protection, CFS structures can suffer reduced lifespan, structural weakening, and costly repairs.

The importance of galvanization cannot be overstated. It extends the service life of CFS members—such as studs, joists, and trusses—by providing barrier protection (isolating steel from the environment), cathodic protection (zinc corrodes preferentially to steel), and a self-healing patina that forms over time. In coastal areas, where salt spray accelerates corrosion, or in humid industrial settings, proper galvanization can mean the difference between a structure lasting decades versus failing prematurely. Studies from organizations like the American Galvanizers Association and the Cold-Formed Steel Engineers Institute (CFSEI) highlight that galvanized CFS can achieve 50-100+ years of durability in benign environments, far outpacing unprotected steel.

Selecting the right galvanization level—such as G40, G60, or G90 in North America, or equivalents like Z275 or AZ150 globally—depends on factors like environmental exposure, building location, and application (e.g., interior vs. exterior). These designations refer to the zinc coating weight, with higher numbers indicating thicker, more protective layers. Beyond pure zinc galvanizing, alternatives like Galvalume (55% aluminum-zinc alloy) offer superior barrier protection in certain conditions, while paint systems can provide additional aesthetic or supplementary defense. However, not all methods are equally acceptable; hot-dip galvanizing remains the gold standard for CFS due to its metallurgical bond and longevity, as outlined in global standards.

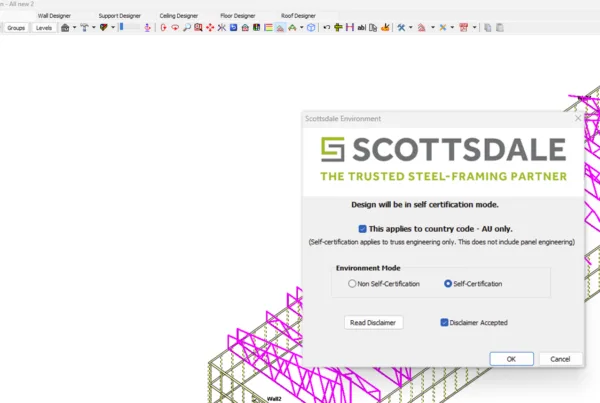

This article delves into the science, calculations, and standards behind galvanization, with a strong focus on how industry leaders like Scottsdale Construction Systems integrate these principles into their advanced roll-forming technology. Scottsdale, a pioneer in CFS manufacturing equipment, produces systems like the Scotpanel and Scottruss roll formers, which are engineered for precision framing using galvanized coils compliant with international norms. Their machines handle a wide range of coating weights and material grades, ensuring global builders can meet stringent corrosion requirements while optimizing efficiency.

Galvanization in Seismic Zones: Ensuring Structural Resilience

In regions prone to earthquakes, the durability of building materials is paramount, as seismic events demand structures that can absorb and dissipate energy without catastrophic failure. Galvanization plays a pivotal role in enhancing the seismic performance of cold-formed steel (CFS) framing by safeguarding against corrosion, which could otherwise compromise the material’s strength and ductility over time. In high-seismic zones, such as those classified under IBC Seismic Design Categories D, E, or F, corrosion-induced degradation—such as pitting or thinning of steel sections—can reduce load-bearing capacity and increase vulnerability during ground shaking.

Research and standards emphasize that galvanized CFS maintains its mechanical properties longer in these areas, particularly when combined with seismic design principles like shear walls, moment-resisting frames, or braced systems. For instance, the Steel Framing Industry Association (SFIA) notes that galvanization protects CFS components, ensuring they meet rigorous safety criteria in seismic designs by preventing rust that could weaken connections or members. Studies on full-scale testing, such as those from the U.S. Army Corps of Engineers, demonstrate that galvanized CFS walls exhibit reliable lateral resistance, with coatings like G90 or equivalent Z275 recommended to counter environmental factors that accelerate corrosion in coastal seismic hotspots like California or Japan.

In seismic retrofits or new constructions, galvanization ensures long-term resilience; for example, NSF-funded projects on CFS rebuilding after earthquakes highlight how corrosion protection allows steel to retain its energy-absorbing capabilities. Scottsdale’s equipment, optimized for high-strength galvanized coils (e.g., G550 with Z275), supports seismic-compliant framing by enabling precise roll-forming of ductile sections that resist both corrosion and dynamic loads. Ultimately, in seismic zones, opting for thicker galvanization levels not only extends service life but also bolsters overall building safety, aligning with codes like ASCE 7 and Eurocode 8.

Calculating Galvanizing Layer Thickness: Formulas and Examples

Understanding the thickness of the galvanizing layer is essential for design and specification, as it directly impacts corrosion resistance and total member dimensions. Galvanizing designations like G60 or Z275 specify the coating weight (mass of zinc per unit area, total for both sides). Thickness is derived from this weight using zinc’s density (approximately 7.14 g/cm³ or 0.256 lb/in³).

Imperial Units (e.g., G Designations)

- Formula for Total Coating Weight (oz/ft²): G value = total zinc weight in oz/ft² (both sides).

- Thickness per Side (mils or inches): Thickness (mils) = [Coating weight (oz/ft²) / 2] × 1.7 (approximate conversion factor for zinc; 1 oz/ft² ≈ 1.7 mils total thickness).

- More precisely: Thickness (inches) = [Weight (oz/ft²) × 0.001685] / 2 (per side).

- Example for G60 (0.60 oz/ft² total):

- Thickness per side = (0.60 / 2) × 1.7 ≈ 0.51 mils (0.00051 inches).

- For a typical Ga. 20 stud (design bare steel thickness ≈ 0.0346 inches or 33 mils), total stud thickness = bare thickness + 2 × coating thickness per side ≈ 0.0346 + 2 × 0.00051 ≈ 0.03562 inches. Design thickness often uses bare metal for structural calculations, but total includes coating for fitment.

SI Units (e.g., Z Designations)

- Formula for Total Coating Weight (g/m²): Z value = total zinc mass in g/m² (both sides).

- Thickness per Side (microns or µm): Thickness (µm) = [Coating mass (g/m²) / zinc density (7.14 g/cm³)] / 2 × 10^4 (for unit conversion; simplified: Thickness (µm) ≈ Mass (g/m²) / 14.28 per side).

- Example for Z275 (275 g/m² total, equivalent to G90):

- Thickness per side ≈ 275 / (7.14 × 2) ≈ 19.25 µm (0.01925 mm).

- For a typical 0.838 mm (33 mil) design bare steel stud (Ga. 20 equivalent), total stud thickness = 0.838 + 2 × 0.01925 ≈ 0.8765 mm. In design, bare metal thickness (BMT) is used for strength, while coating adds negligible structural value but enhances durability.

These calculations relate to common CFS gauges: Ga. 18 (design bare 0.0474 in), Ga. 20 (design bare 0.0346 in), where coatings like G40 (thinner, for interior) add minimal thickness but are crucial for protection. Always verify with standards like ASTM A653, as actual thicknesses may vary due to manufacturing tolerances.

Acceptable Receiving Requirements and Measurement

In cold-formed steel framing, the “design thickness” refers to the nominal bare (uncoated) steel thickness used in structural calculations. However, standards allow for manufacturing variations. According to CSA 136, AISI S100, S220, and S240 (which reference ASTM A1003 for steel sheet), the minimum delivered average base metal thickness (BMT) must be at least 95% of the design thickness, with no individual measurement less than 90% of the design thickness. This applies to the uncoated steel; the galvanizing layer is not included in the design thickness but must be accounted for during inspection.

To determine acceptability upon receipt:

- Measure the Total Thickness: Use a calibrated micrometer (e.g., C-shaped outside micrometer for accuracy on flat sections like the stud web or knockout areas to avoid rounded edges). Take multiple measurements (at least three, averaged) on uncoated-equivalent areas.

- Subtract the Coating Thickness: Calculate the nominal coating thickness based on the designation (as shown in formulas above) and subtract the total coating (both sides) from the measured total thickness to estimate BMT. For precise verification, use non-destructive methods like magnetic thickness gauges (per ASTM E376) or strip the coating on a sample (using acid per ASTM A90/A90M) to measure BMT directly.

- Check Against Tolerances: Verify the average BMT ≥ 0.95 × design thickness, and no single BMT < 0.90 × design thickness. If below, the material may not comply.

Imperial Example (Ga. 20, G60):

- Design bare thickness = 0.0346 inches (33 mils).

- Minimum average BMT = 0.95 × 0.0346 ≈ 0.03287 inches.

- Nominal G60 coating total (both sides) ≈ 1.02 mils (0.00102 inches).

- If measured total thickness = 0.0350 inches, estimated BMT = 0.0350 – 0.00102 ≈ 0.03398 inches (> 0.03287, acceptable).

- If measured total = 0.0335 inches, BMT ≈ 0.03248 inches (< 0.03287 average min, potentially reject if average of samples fails).

SI Example (0.838 mm design bare, Z275):

- Design bare thickness = 0.838 mm.

- Minimum average BMT = 0.95 × 0.838 ≈ 0.7961 mm.

- Nominal Z275 coating total (both sides) ≈ 38.5 µm (0.0385 mm).

- If measured total = 0.880 mm, estimated BMT = 0.880 – 0.0385 ≈ 0.8415 mm (> 0.7961, acceptable).

- If measured total = 0.830 mm, BMT ≈ 0.7915 mm (< 0.7961, check averages).

ASTM A1003 also specifies sheet tolerances (e.g., ±0.003 inches for 0.023-0.040 in thick sheets), but for formed members, AISI tolerances apply. In global standards like EN 10346 or AS 1397, similar principles hold, with min BMT at 95-100% of specified, measured excluding coating. Always consult project specs and perform measurements per code for compliance.

Equivalence Table: G vs. Z Designations

G designations (imperial, oz/ft²) and Z (metric, g/m²) are interchangeable via the conversion: 1 oz/ft² ≈ 305.15 g/m². Here’s a comparison table for common coatings:

| G Designation | Coating Weight

(oz/ft² total) |

Equivalent

Z Designation |

Coating Weight

(g/m² total) |

Typical Thickness per Side

(mils/µm) |

|---|---|---|---|---|

| G30 | 0.30 | Z90 | 90 | 0.26 mils / 6.3 µm |

| G40 | 0.40 | Z120 | 120 | 0.34 mils / 8.4 µm |

| G60 | 0.60 | Z180 | 180 | 0.51 mils / 12.6 µm |

| G90 | 0.90 | Z275 | 275 | 0.77 mils / 19.3 µm |

| G115 | 1.15 | Z350 | 350 | 0.98 mils / 24.5 µm |

This equivalence ensures global compatibility; for instance, Scottsdale’s roll formers from all the five families – Scotpanel, Scottruss, KFS Framemaker, KFD Framemaker, and KSE, will process coils across both designations seamlessly.

Note on Z vs. AZ Designations: The Z designation (e.g., Z275) specifically refers to pure zinc (or hot-dip galvanized) coatings, where the coating is primarily zinc with a small amount of aluminum added for process control. In contrast, AZ designations (e.g., AZ150 or AZ200) indicate 55% aluminum-zinc alloy coatings (often called Galvalume® or similar), which consist of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon. These AZ coatings provide superior barrier protection (due to the higher aluminum content forming a more stable oxide layer) and often exhibit 2-4 times longer service life in atmospheric and mildly corrosive environments compared to equivalent zinc (Z) coatings, especially in coastal or industrial settings. However, pure zinc (Z) coatings offer better sacrificial protection at cut edges or scratches.

These distinctions are key in standards like ASTM A653 (for zinc) vs. ASTM A792 (for 55% Al-Zn), AS 1397 (where both Z and AZ classes are defined, with AZ often preferred for enhanced durability in humid/tropical climates), and EN 10346 (which includes AZ equivalents). When specifying or comparing materials globally, confirm the coating type (Z for zinc, AZ for aluminum-zinc alloy) to ensure the appropriate corrosion performance for the application. Scottsdale’s equipment supports both types seamlessly for versatile global compliance.

The Superiority of Riveted Connections in Corrosion Protection: Why Scottsdale’s Scotpanel Leads the Way

When it comes to assembling CFS frames, the choice of connection method is pivotal—not just for structural integrity, but for long-term corrosion protection. Riveted connections, as opposed to screws, offer unparalleled advantages, particularly in safeguarding the vulnerable areas around fastener holes where the galvanizing layer may be disrupted during installation.

Riveted connections create a clamping mechanism that seals the joint tightly, preventing moisture ingress and protecting the bare steel edges from exposure. This “clamping effect” minimizes galvanic corrosion at the hole perimeter, where screws can loosen over time due to vibration or thermal cycling, allowing water and salts to penetrate. In contrast, rivets form a permanent, vibration-resistant bond that maintains compression, effectively extending the life of the galvanizing protection. Studies on CFS connections show that riveted joints reduce corrosion rates by up to 30-50% in humid or coastal environments compared to screwed ones, as they avoid the micro-gaps that screws inevitably create.

Enter Scottsdale Construction Systems’ Scotpanel roll formers—the ultimate game-changer optimized for deploying these superior riveted connections. Scottsdale’s innovative technology, like the Scotpanel 5090/7090 series, automates high-precision riveting, producing frames with double-rivet joints for enhanced strength and corrosion resistance. Why settle for screws when rivets deliver faster assembly (up to 20% quicker in factory settings), superior shear strength, and unmatched durability? Scottsdale’s systems eliminate the guesswork, ensuring every joint is flawlessly riveted for structures that stand the test of time. Don’t compromise—choose Scottsdale’s Scotpanel for the strongest, most corrosion-proof CFS framing available. It’s not just a connection; it’s a revolution in reliability!

Expected Time Protection: Lifespan of Galvanization Levels

The service life of galvanized CFS varies by coating and environment:

| Coating | Indoor/Dry (Years) | Suburban/Mild (Years) | Coastal/Harsh (Years) | Industrial (Years) |

|---|---|---|---|---|

| G40 | 200-500+ | 50-100 | 10-30 | 20-50 |

| G60 | 300-1000+ | 70-150 | 20-50 | 30-70 |

| G90 | 500-1000+ | 100-200+ | 30-75 | 50-100 |

Scottsdale Construction Systems: Tailored for Global Corrosion Standards

Scottsdale Construction Systems specializes in advanced CFS roll-forming equipment, including the Scotpanel (for complete framed assemblies) and Scottruss (for superior engineered steel trusses), designed to fabricate high-precision frames from galvanized coils. Their machines support thicknesses from 0.48-2.58 mm, grades like G550 (Fy of up to 550 MPa), and coatings from G40 to G90/Z275. All equipment complies with ASTM A653 (North America), AS 1397 (Australia/NZ), and EN 10346 (Europe), ensuring seamless integration of corrosion protection. From their steel coil ordering guide, Scottsdale emphasizes Z275/AM150 for high-corrosion apps, with decoilers handling global coil specs for efficient production.

As a global enterprise, Scottsdale keenly understands regional requirements, customizing roll formers for compliance worldwide. Whether it’s AISI S100 in the US or Eurocode 3 in Europe, Scotsdale’s roll forming technology is fully optimized for the local requirements and regulations. The following sections explore the propriety of various galvanizing layers for specific applications. Scottsdale publishes a manual summarizing ordering instructions pertaining to the coil processed through all its framing machines, which can be publicly accessed at this link.

North America (US and Canada): AISI S100, ASTM A653

In North America, AISI S100 governs CFS design, requiring ASTM A653 for galvanizing. Minimums: G60/AZ50 for structural (CP60 equivalent), G40/AZ50 for non-structural. G90 is recommended for exteriors or coastal (e.g., within 300-3000 ft of ocean). CFSEI Tech Notes emphasize G90 in partially sheltered areas for 50-70+ years.

| Coating Designation | Minimum Coating Weight (oz/ft² total both sides) | Typical Thickness per Side (mils) | Application |

|---|---|---|---|

| G40 | 0.40 | 0.34 | Non-structural, interior dry areas |

| G60 | 0.60 | 0.51 | Structural, interior wet areas or mild exterior |

| G90 | 0.90 | 0.77 | Exterior walls, coastal or harsh environments |

| AZ50 | 0.50 | 0.80 | Alternative to G for better barrier protection |

Australia and New Zealand: AS 1397

AS 1397:2021 specifies zinc (Z) and aluminum-zinc (AZ) coatings for CFS, with minimum coating masses for formability and structural grades up to 5.0 mm thick. Common designations include Z100 to Z600 for zinc, and AZ150/AZ200 for aluminum-zinc (55% Al-Zn). Higher coatings like Z275 are standard for structural applications in moderate environments, while Z450+ suits severe coastal zones. Scottsdale’s systems are optimized for these, providing 50-100+ years in mild climates.

| Coating Designation | Minimum Coating Mass (g/m² total both sides) | Typical Thickness per Side (µm) | Application |

|---|---|---|---|

| Z100 | 100 | 7 | Interior, low corrosion risk |

| Z200 | 200 | 14 | Mild exterior or suburban |

| Z275 | 275 | 19 | Structural, moderate coastal (1-10 km inland) |

| Z350 | 350 | 25 | Harsh industrial or coastal (0.1-1 km) |

| Z450 | 450 | 32 | Severe marine or aggressive environments |

| AZ150 | 150 | 20 | Alternative to Z for enhanced barrier in humid areas |

| AZ200 | 200 | 27 | High-corrosion coastal applications |

Europe (including EN 10346 and Eurocode 3)

EN 10346 covers hot-dip coatings for CFS, mandating Z275 minimum for structural steels (S220GD-S550GD); Eurocode 3 (EN 1993-1-3) designs for corrosion via class (e.g., C3 for moderate). Coatings include Z (zinc), ZA (zinc-aluminum), ZM (zinc-magnesium), AZ (aluminum-zinc), ensuring 50-100+ years. ZM offers improved performance in humid conditions. Scottsdale tailors for S350GD+Z, with thicker coatings for C4/C5 classes.

| Coating Designation | Minimum Coating Mass (g/m² total both sides) | Typical Thickness per Side (µm, range) | Application |

|---|---|---|---|

| Z100 (Zinc) | 100 | 7 (5-12) | Low carbon steels, interior |

| Z200 | 200 | 14 (10-20) | Construction steels, mild urban |

| Z275 | 275 | 20 (15-27) | Structural (S220GD-S550GD), moderate industrial |

| Z350 | 350 | 25 (19-33) | High corrosion, coastal C3-C4 |

| Z450 | 450 | 32 (24-42) | Severe environments, C5 |

| ZA130 (Zn-Al) | 130 | 10 (7-15) | Improved formability, humid areas |

| ZA200 | 200 | 15 (11-21) | Multiphase steels, better than Z in salt |

| ZM070 (Zn-Mg) | 70 | ~5 (min) | Advanced, high humidity (not in doc, but standard) |

| ZM120 | 120 | ~8 | Structural, enhanced cut-edge protection |

| AZ100 (Al-Zn) | 100 | 13 (9-19) | Construction up to S350GD, marine |

| AZ150 | 150 | 20 (15-27) | High proof strength, industrial |

South America (Brazil, Argentina, etc.): ABNT NBR, ASTM Influences

In South America, practices for CFS galvanization often align with international standards due to trade and imports, with local adaptations. Brazil’s ABNT NBR 15217 and NBR 7008 govern galvanized steel, drawing from ASTM A653 and ISO 9223 for corrosion classification. Minimum Z275 is common for structural CFS in humid/tropical climates; Argentina follows IRAM standards, similar to ASTM, with G90/Z275 for coastal areas. Higher coatings like Z350 are used in aggressive industrial zones. Scottsdale’s versatile systems support these, ensuring compliance for exports.

| Coating Designation | Minimum Coating Mass

(g/m² total both sides) |

Typical Thickness per Side

(µm) |

Application |

|---|---|---|---|

| Z180 | 180 | 12.6 | Interior, mild environments |

| Z275 | 275 | 19 | Structural, moderate humidity/coastal |

| Z350 | 350 | 25 | Harsh industrial or tropical coastal |

| AZ150 | 150 | 20 | Alternative for barrier in humid areas |

| AZ200 | 200 | 27 | Severe corrosion zones |

Africa (South Africa, Nigeria, Kenya): SANS/ISO, Local Adaptations

African practices vary, with South Africa leading via SANS 10400 (building code) and SANS/ISO 14713 for galvanizing, requiring Z275 minimum for structural CFS; higher Z450 for marine/industrial. Nigeria and Kenya often adopt BS EN 10346 or ASTM A653 due to imports, with Z200-Z350 common in urban/coastal projects. Emphasis on ISO 9223 corrosion classes (C3-C5 in coastal areas). Scottsdale’s equipment handles these standards, aiding infrastructure growth.

| Coating Designation | Minimum Coating Mass

(g/m² total both sides) |

Typical Thickness per Side

(µm) |

Application |

|---|---|---|---|

| Z200 | 200 | 14 | Interior/mild urban |

| Z275 | 275 | 19 | Structural, moderate coastal |

| Z350 | 350 | 25 | Industrial/high humidity |

| Z450 | 450 | 32 | Severe marine environments |

| AZ150 | 150 | 20 | Enhanced barrier for coastal |

Service life: In C3 (moderate), Z275 ~15-40 years; C5 (severe coastal), Z450 10-30 years, varying by local climate.

South-East Asia (Singapore, Malaysia, Indonesia, Thailand): SS/MS/SNI EN, JIS/ASTM

South-East Asia blends EN, JIS, and ASTM influences. Singapore’s SS EN 10346 mandates Z275 for structural; Malaysia’s MS EN 10346 similar, with AZ150 for humid tropics. Indonesia’s SNI 07-2054 (based on JIS G3302/ASTM) requires Z180+; Thailand follows TIS 50 or ASTM. Focus on C4-C5 classes due to monsoons/coastal exposure. Scottsdale optimizes for these, supporting rapid urbanization.

| Coating Designation | Minimum Coating Mass (g/m² total both sides) | Typical Thickness per Side (µm) | Application |

|---|---|---|---|

| Z180 | 180 | 12.6 | Interior/low corrosion |

| Z275 | 275 | 19 | Structural, urban/monsoon |

| Z350 | 350 | 25 | Coastal/industrial |

| AZ150 | 150 | 20 | Humid/tropical barrier |

| AZ200 | 200 | 27 | Severe marine |

Types of Corrosion Protection: Acceptability and Alternatives

While hot-dip galvanizing is the benchmark for CFS corrosion protection due to its robust metallurgical bond and sacrificial properties, several alternatives exist, each with specific advantages, limitations, and acceptability under standards like ASTM A653 or EN 10346. Selection depends on environmental exposure, cost, and performance needs; however, alternatives may require additional testing for equivalence in structural applications.

- Hot-Dip Galvanizing (Zinc-Based): The preferred method for CFS, involving immersion in molten zinc for a durable, self-healing coat (e.g., G60/Z180). Pros: Excellent cathodic protection, long lifespan (50-100+ years), widely acceptable in all standards. Cons: Higher initial cost, potential for distortion in thin sections. Universally acceptable for structural use.

- Galvalume (55% Aluminum-Zinc Alloy): A hot-dip alternative (e.g., AZ150) offering superior barrier resistance in atmospheric and marine environments. Pros: Better heat reflection, up to 2-4 times longer life than zinc in certain conditions, reduced white rust. Cons: Less effective in alkaline soils, higher cost. Acceptable under ASTM A792 and equivalents; ideal for coastal CFS but not for all soil exposures.

- Zinc-Magnesium (ZM) Coatings: Advanced hot-dip options (e.g., ZM120) with magnesium for enhanced cut-edge protection. Pros: Superior corrosion resistance in humid/salty conditions (up to 3x better than zinc), improved formability. Cons: Limited availability, slightly higher cost. Acceptable in EN 10346; gaining traction for automotive and construction CFS.

- Zinc-Iron, Zinc-Nickel, or Zinc-Aluminum Alloys: Electroplated or hot-dip variants (e.g., zinc-nickel for automotive). Pros: Better hardness and weldability than pure zinc, good in industrial atmospheres. Cons: Thinner coatings, less sacrificial protection. Acceptable as alternatives but often require equivalence testing per AISI standards; not primary for structural CFS.

- Equivalent (EQ) or High-Performance Coatings: Polymeric or alloy-based. Pros: Comparable corrosion resistance to G60 at lower zinc weights, eco-friendly. Cons: May need field verification. Acceptable for CFS framing under specific approvals; used where galvanizing is overkill.

- Epoxy or Paint Systems (e.g., Epoxy Polyamine, Aluminized Epoxy Mastic): Barrier coatings applied over bare or primed steel. Pros: Customizable colors, additional UV protection, cost-effective for interiors. Cons: No sacrificial action, prone to chipping/scratches, shorter lifespan (10-30 years). Not standalone for structural CFS—use as supplementary over galvanizing; acceptable for non-exposed applications but inferior in harsh environments.

- Metal Spraying (Thermal Spray Zinc): Zinc/aluminum sprayed onto steel. Pros: Variable thickness, repairable on-site, good for large structures. Cons: Less uniform bond, higher labor costs. Acceptable for repairs or alternatives to galvanizing per international standards; not common for factory CFS.

- Iron Oxide Primers: Red oxide-based for temporary protection. Pros: Low cost, easy application. Cons: Minimal long-term resistance, not sacrificial. Rarely acceptable as primary; better for storage or as base for paints.

Choose based on environment; hot-dip and Galvalume are most reliable for CFS longevity, while others suit niche or supplementary roles. Always consult CFSEI guidelines for equivalence. If you are using an advanced Scottsdale steel framing roll former, and you want to find out more about galvanizing requirements, please contact us at rollformers@scottsdalesteelframes.info to speak with one of our experts.