Self-certification streamlines how light-gauge steel trusses are designed, validated, and fabricated for compliant projects using roof trusses and floor trusses following the Australian Building Codes Board. By combining advanced roll forming technology with integrated software workflows and roll forming of CFS truss systems, qualified customers can complete compliant designs faster, reduce engineering delays, and move directly from digital models into production with confidence.

What Self-Certification Means for Light-Gauge Steel Trusses

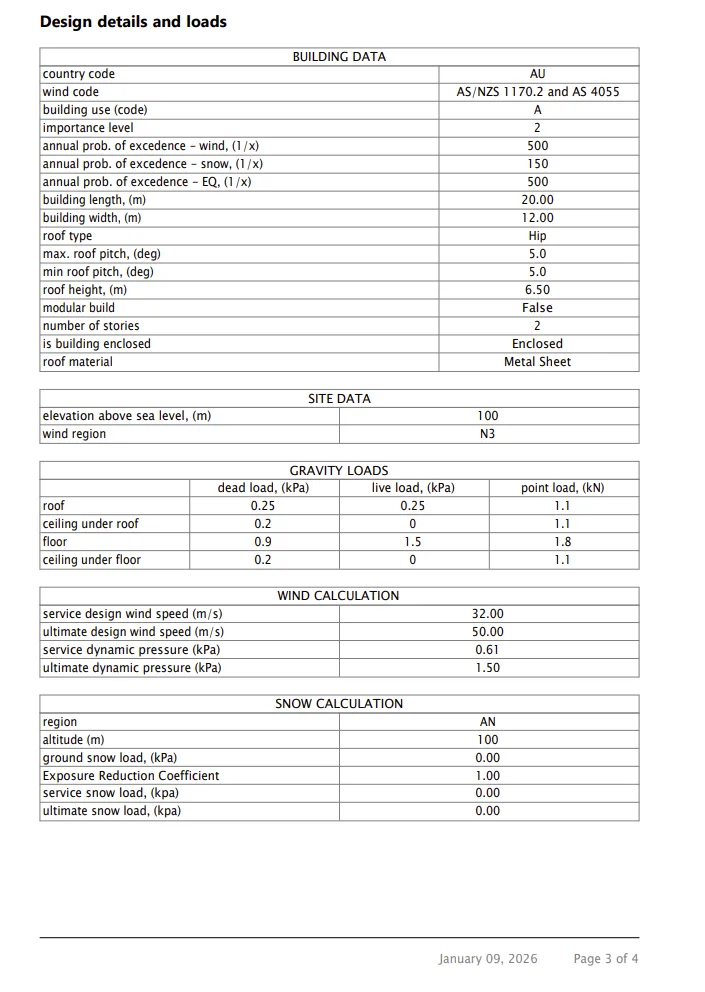

Self-certification allows approved users to certify compliant designs for light-gauge steel trusses without relying on external engineering sign-off, as long as the project meets the prescribed limitations of the Australian Building Codes Board (ABCB) and the ABCB Structural Software Protocol. This applies specifically to CFS roof trusses and floor trusses manufactured through validated design rules and automated checks. The software verifies geometry, loading, and compliance in real time, ensuring every CFS truss design remains within allowable parameters.

For customers adopting roll forming technology in Australia, self-certification eliminates unnecessary handoffs and compresses project timelines. When paired with Scottsdale’s roll forming of CFS truss systems, the digital design output connects directly to fabrication, improving project timelines, accuracy, and repeatability across steel framing production.

The Self-Certification Process for Roof Trusses and Floor Trusses

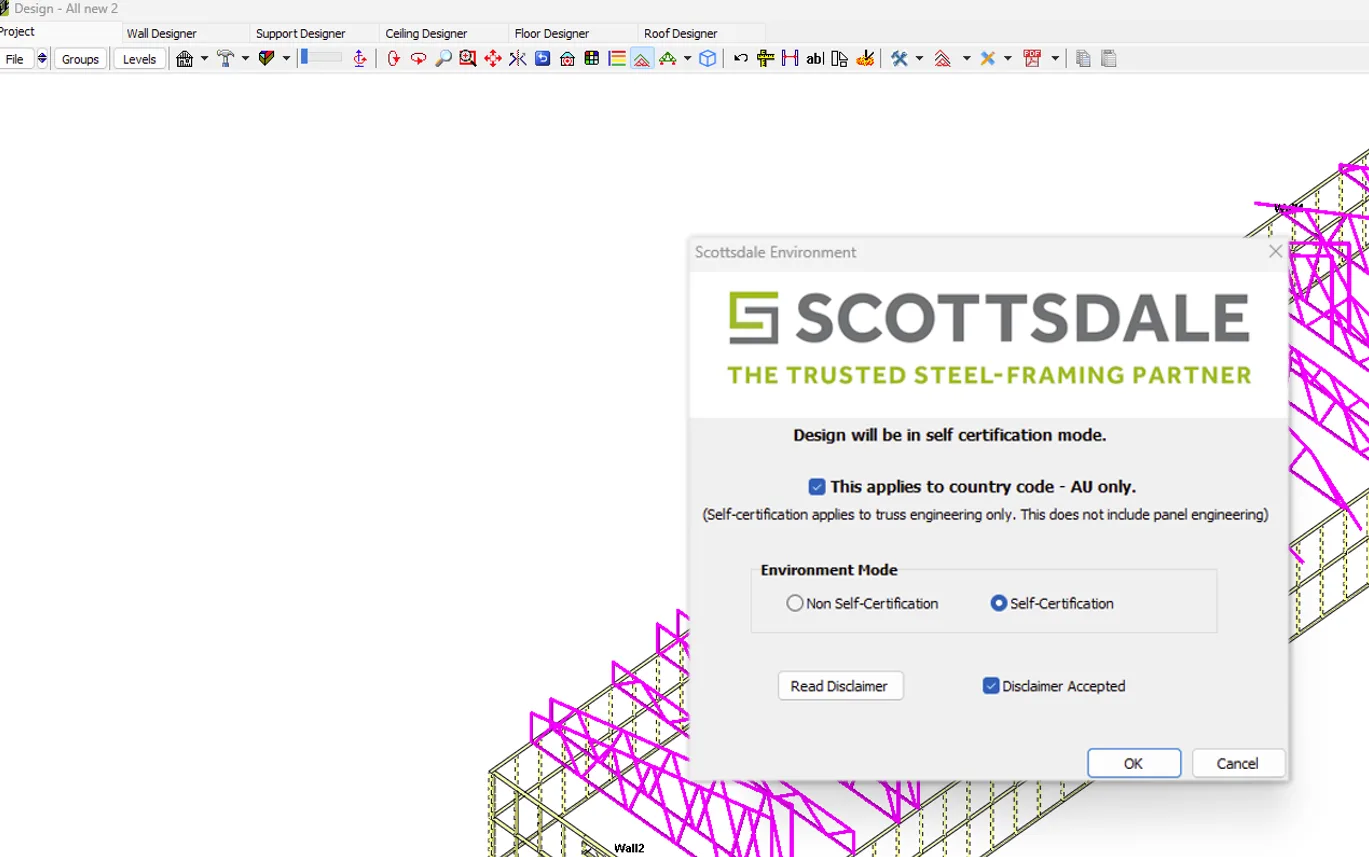

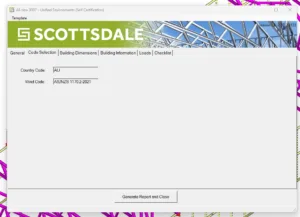

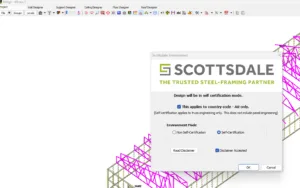

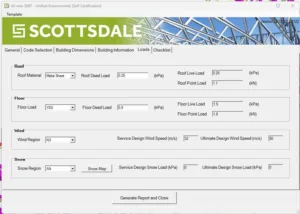

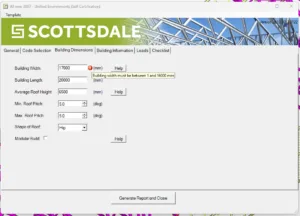

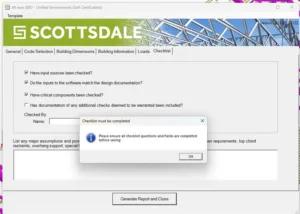

To qualify for self-certification, companies must operate the approved ScotSteel truss design software and follow the requirements of the Australian Building Codes Board. The workflow is optimized for roof trusses and floor trusses, allowing detailers, designers, fabricators, and engineers to generate fully compliant documentation directly from the platform.

To design CFS truss systems, the designer must have access to ScotSteel design software.

ScotSteel is available for standalone purchase and is included complimentary with the purchase of Scottsdale roll forming machine(s).

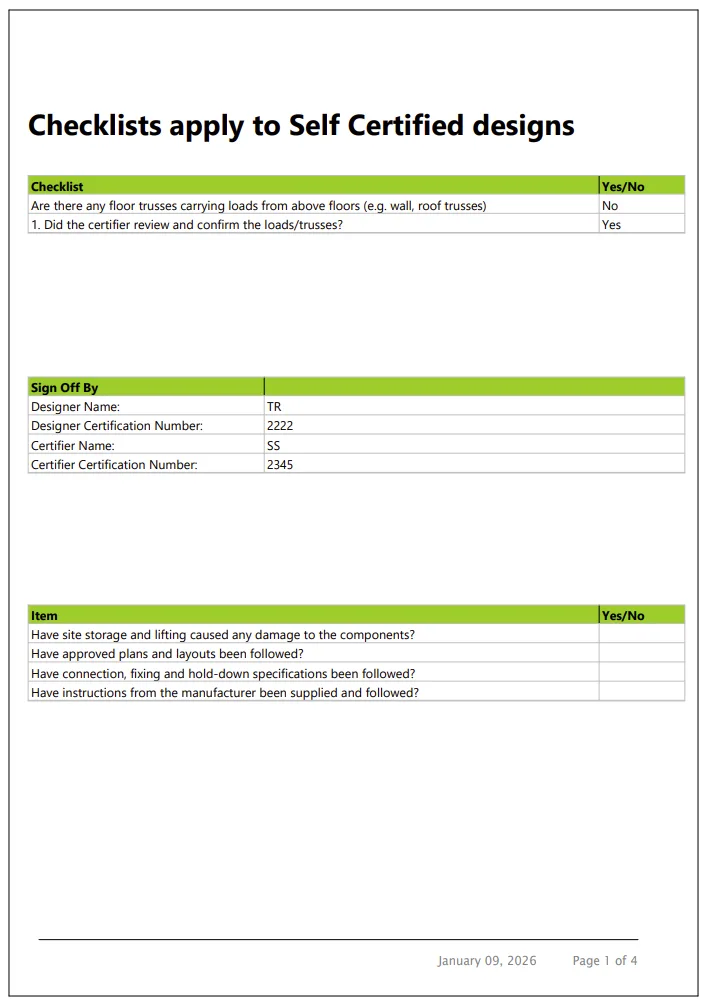

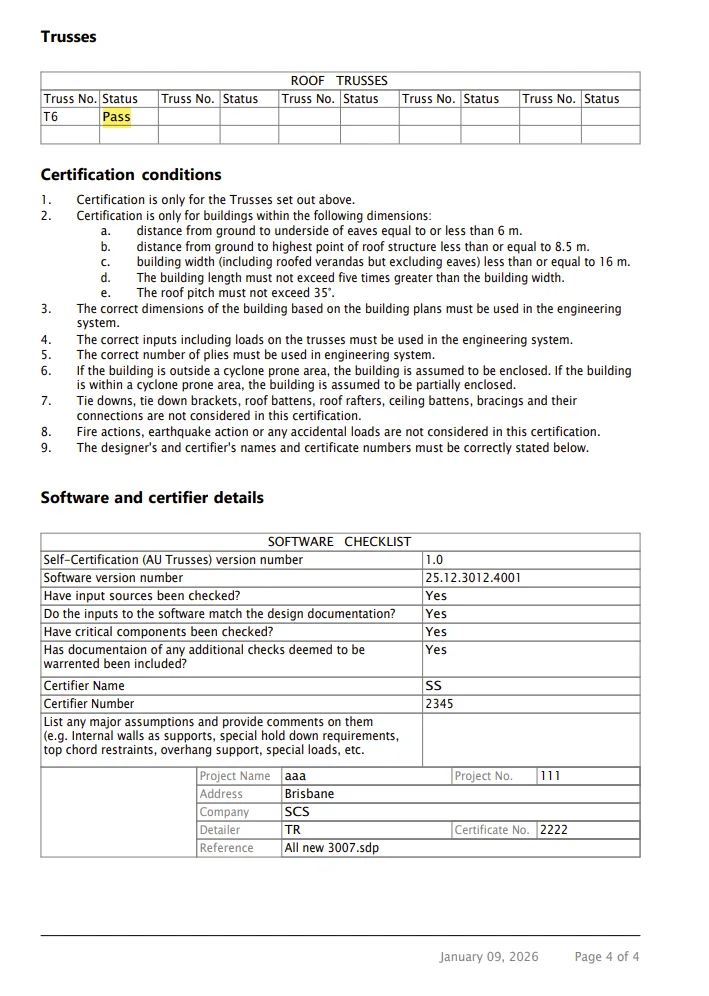

Two individuals within each company must complete the certification process: one acting as the “Designer” and one as the “Checker”. Each individual receives a unique certification number tied to their name. Training covers the full design workflow for light-gauge steel trusses, profile selection, load validation, and automated rule checking. Once training is complete, participants complete a structured assessment reviewed by the Scottsdale team. Successful candidates receive a unique certification number that verifies their ability to produce compliant light-gauge steel truss designs aligned with the Australian Building Codes Board.

Due to ScotSteel‘s embedded guardrails, designs that exceed allowable limits cannot proceed in the design process. This ensures that every certified output for roof trusses and floor trusses remains within the approved scope while supporting consistent manufacturing through roll forming of CFS truss systems.

How Roll Forming Technology Connects Design to Fabrication

The real advantage of self-certification emerges when integrated with our roll forming technology. Approved designs flow seamlessly from ScotSteel software into machine instructions, eliminating translation errors, reducing rework, and the involvement of third-party engineering. This digital thread supports consistent production of light-gauge steel trusses at scale while maintaining tight tolerances.

By leveraging roll forming of CFS truss systems, manufacturers can fabricate truss systems efficiently and repeatably. The same dataset used to certify roof trusses and floor trusses drives automated cutting, punching, and forming, accelerating throughput and improving shop productivity. This closed-loop workflow enhances fabrication, compliance, and operational control under the Australian Building Codes Board.

Click on the Self-Certification report pages below to enlarge and review.

Business Benefits of Self-Certification of CFS Truss Systems

Self-certification delivers measurable business advantages. Companies avoid third-party engineering delays and reduce recurring certification costs. Faster turnaround enables same-day design and fabrication of roof trusses and floor trusses, improving responsiveness to project schedules. This agility strengthens competitiveness while expanding capacity for higher volumes of light-gauge steel trusses.

Operationally, teams gain confidence knowing that every design aligns with the Australian Building Codes Board and is validated by built-in checks. Combined with roll forming technology, production becomes predictable, scalable, and easier to manage. The learning curve is structured and supported, making the adoption of roll forming of CFS truss systems accessible even for growing fabrication teams.

Strategically, self-certification empowers manufacturers to bring more design capability in-house, unlock faster cash flow, and increase margins through controlled production of roof trusses and floor trusses. The result is a resilient workflow that balances speed, compliance, and quality while maximizing the return on roll forming technology investments.

Self-certification enables fabricators to capture more roof truss and floor truss design work while expanding their overall business capacity. Designs can be completed in a single day and immediately released to production, allowing same-day fabrication of CFS truss systems and faster project turnaround.

Below is a summary of self-certification benefits:

- Enables users to independently certify light-gauge steel truss designs without third-party engineering sign-off.

- Ensures every roof truss and floor truss design remains within the Australian Building Code Board and ABCB Structural Software Protocol through built-in software validation.

- Real-time automated checks verify geometry, loading, and compliance before fabrication.

- Reduce project timelines by eliminating unnecessary handoffs and external engineering delays.

- Enables same-day CFS truss modeling and fabrication.

- Reduces rework and translation errors through direct digital-to-machine workflows.

- Increases throughput and shop productivity through direct design-to-production workflows.

- Increase margins through controlled in-house production.

- Creates opportunities for self-certification to become a revenue stream.

- Allows fabricators to bring more CFS truss design capability in-house.

- Strengthens competitiveness through faster delivery and lower costs.

- Enables manufacturers to respond quickly to market demand and new opportunities.

Why Customers Adopt Self-Certification of Light-Gauge Steel Trusses

Customers choose to enroll in the self-certification process because it creates autonomy, accelerates delivery, and strengthens technical capability. The ability to independently certify light-gauge steel trusses under the Australian Building Codes Board shortens project cycles and reduces dependency on external engineering consultants. When integrated with roll forming of CFS truss systems, the entire process, from concept to fabrication, becomes streamlined and predictable.

As demand for roof trusses and floor trusses continues to grow, scalable workflows supported by roll forming technology enable manufacturers to respond confidently to market opportunities. Self-certification is not just a compliance pathway; it is a strategic operational upgrade that drives efficiency, consistency, and long-term growth across modern steel framing operations.

Q: What is self-certification of light-gauge steel trusses?

A: Self-certification allows qualified users to independently certify compliant light-gauge steel trusses for approved roof trusses and floor trusses without third-party engineering sign-off, provided the design remains within the limits of the Australian Building Code Board.

Q: Which applications are covered under self-certification?

A: Self-certification applies specifically to roof trusses and floor trusses designed within defined geometric and structural limits and validated through ScotSteel software aligned with the Australian Building Code Board.

Q: Who can become self-certified?

A: Anyone. Detailers, designers, fabricators, engineers, and any design professionals can enroll in Scottsdale’s self-certification program. Using approved ScotSteel truss software, any individual can become certified. Each company must certify a “Designer” and a “Checker” to support compliant delivery of roof trusses and floor trusses.

Q: Why is self-certification valuable?

A: Customers gain faster turnaround, reduced engineering costs, predictable compliance with the Australian Building Code Board, and tighter integration between design and fabrication through roll forming technology and roll forming of CFS truss systems. Self-certification can also become a revenue stream for fabricators or any individual.

Q: How does self-certification improve business performance?

A: Self-certification allows companies to deliver more light-gauge steel trusses efficiently, scale production of roof trusses and floor trusses, and strengthen operational control while maintaining consistent quality and code compliance. By reducing the engineering timeline and costs, fabricators increase their margins and revenue on projects. Fabricators can also position themselves to win more projects with lower costs and shorter project delivery times.

Q: How does roll forming technology support the process?

A: Roll forming technology connects certified digital designs directly to automated fabrication, ensuring accuracy, repeatability, and faster production of compliant CFS truss systems.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Best Steel Framing Results with Advanced Roll Forming Technology

- Blog – 7 Reasons ScotStruct Makes Complete Steel Framing Design Easy

- Blog – Overcome Complex CFS Truss Design with New Steel Framing Technology

- Blog – All You Need to Know: Cold-Formed Steel Trusses vs. Steel Joists

- Video – Unlimited Possibilities with Scottruss High-Tech Roll Forming Machine

- Video – Steel Framing Fabrication Process with Scotpanel and Scottruss Roll Forming Systems

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.