The construction industry increasingly relies on steel framing as a versatile, sustainable, and highly accurate solution for residential, commercial, and modular buildings. To meet modern engineering challenges, software platforms such as ScotStruct have become essential. ScotStruct empowers engineers and designers by simplifying steel framing design, automating calculations, and ensuring compliance with international building codes. Its seamless integration with ScotSteel makes cold-formed steel framing design faster, more reliable, and more accurate.

Simplifying Steel Framing Design

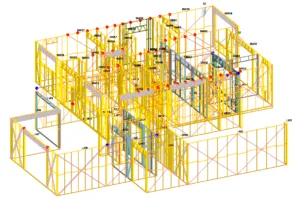

ScotStruct is an advanced engineering tool that performs structural analysis with dedicated modules for walls, bracing, openings, and more. Once basic loads are defined, ScotStruct generates load combinations based on building location, type, and other details. With ScotStruct, engineers can analyze load-bearing walls, check lintels and openings, validate bracing systems, and ensure every connection and cold-formed steel member in a steel framing project meets code requirements. The result is a set of comprehensive engineering reports that streamline cold-formed steel framing design. This all-in-one approach removes the need for multiple software programs, saving time and reducing errors.

Below are seven key reasons why ScotStruct makes steel framing design easy for designers and engineers at every level.

#1

Direct Strength Method in Cold-Formed Steel Framing Design

One of ScotStruct’s core strengths is its reliance on the Direct Strength Method (DSM) for structural analysis. The DSM represents a modern approach in cold-formed steel design, moving beyond older engineering methods that required Effective Width Method (EWM) calculations. Instead of approximating a section’s behavior, the DSM uses elastic buckling solutions as inputs for determining the strength of cold-formed steel members.

This method significantly improves the accuracy of steel framing design, especially for thin-walled members prone to local and distortional buckling. By capturing these complex behaviors, the DSM allows engineers to confidently push the efficiency of cold-formed steel framing. It also aligns with international design codes, ensuring that projects remain compliant while maximizing material savings.

Image above shows examples of distortional buckling in resilient channels.

For engineers working with intricate systems such as trusses, walls, and bracing, the DSM provides a robust framework that enhances the precision of cold-formed steel framing design. Learn more about the difference between EWM vs. DSM by reading “The Complete Cold-Formed Steel Design Guide: All You Need to Know”.

#2

Designing for Strength and Serviceability in Cold-Formed Steel

In steel framing design, it is essential to distinguish between strength requirements and serviceability requirements. Designing for strength ensures that the structural members have the capacity to resist ultimate loads without failure. This means checking that walls, studs, lintels, and connections can handle peak loads from wind, snow, or seismic events.

Serviceability, on the other hand, deals with how the structure performs under normal, everyday conditions. For cold-formed steel framing, this includes checking deflections, vibrations, and overall stiffness to ensure comfort and functionality. While strength protects against collapse, serviceability protects against excessive movement, cracked finishes, and long-term wear. ScotStruct simplifies this balance by performing both sets of checks automatically, making cold-formed steel framing design more efficient and reliable.

This article, “A Comparison of General Design and Load Requirements in Building Codes in Canada, Mexico, and the United States”, by the American Institute of Steel Construction, is an excellent resource for understanding the safety and serviceability provisions in the codes and standards that govern the design of new buildings and other structures.

#3

Load-Bearing Walls and Non-Load-Bearing Walls in Steel Framing

Load-bearing walls are a critical element in steel framing design. These walls transfer gravity loads from floors and roofs down to the foundation, and they must also resist lateral loads from wind and earthquakes. In some cases, load-bearing walls also serve as fire walls, preventing fire spread between sections of a building. ScotStruct performs engineering checks to ensure that these walls meet structural and safety standards.

Non-load-bearing walls, in contrast, are partitions used to divide interior spaces. While they do not carry vertical loads, they still require careful detailing in cold-formed steel framing design to maintain durability and accommodate openings such as doors and windows. ScotStruct’s integrated modules make it simple to evaluate both wall types in a single model.

#4

Designing Openings in Cold-Formed Steel Framing

Openings for doors, windows, staircases, or skylights may present challenges in steel framing design. Loads must be redirected around these openings using properly designed studs, sills, and lintels. If load paths are not clearly defined, these areas can become weak points in a structure.

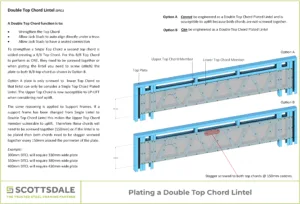

ScotStruct provides dedicated tools for analyzing openings in cold-formed steel framing design, ensuring that members are sized correctly and connections are strong enough to carry loads. The software supports advanced designs, such as double top chord lintels, allowing engineers to handle more complex architectural layouts with confidence.

#5

Connections and Joints in Cold-Formed Steel Framing

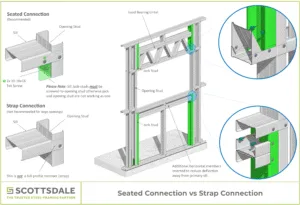

Connections are often the most vulnerable parts of a steel framing system. The choice between rivets and screws, for example, can significantly impact performance. Rivets are faster to install, provide consistent strength, and avoid over-tightening issues. Screws in steel framing should be monitored to avoid stripping or misalignment.

Beyond fasteners, seated connections and other joint designs must be carefully engineered to avoid weakening the cold-formed steel framing system. ScotStruct allows engineers to check connections directly within the design process, ensuring that modifications to cold-formed steel members, such as punches or cuts, do not compromise their structural integrity.

Learn more about how to properly design cold-formed steel members at joints by reading our article “Everything You Need to Know About Light-Gauge Steel Seated Connections”.

#6

Lateral Force Resisting Systems in Steel Framing Design

In cold-formed steel framing design, resisting lateral loads is critical. ScotStruct supports the design of primary lateral force resisting systems: bracing and shear walls.

Shear walls use sheathing and stiff vertical elements to transfer lateral loads, making them highly effective in high-seismic or high-wind zones. Shear walls are inherently stiff elements and are extremely effective at resisting lateral loads. Bracing systems such as K-bracing or X-bracing, also known as cross-bracing, offer more cost-effective alternatives for many buildings, using steel members to triangulate and resist lateral forces.

By enabling engineers to configure lateral force resisting types, connection patterns, and stud layouts, ScotStruct provides a flexible platform for optimizing lateral systems in steel framing design.

#7

Engineering Reporting and Compliance

A key advantage of ScotStruct is its ability to generate detailed engineering reports for cold-formed steel framing design. Reports can be customized as summary, standard, or detailed outputs, making it easy to communicate with engineers of record (EORs), clients, and building officials. The pass/fail system ensures clarity, while the ability to quickly modify designs supports an iterative design process.

With ScotStruct, cold-formed steel framing projects achieve both speed and compliance, supporting contractors and engineers in delivering safe, efficient, and code-compliant buildings.

Cold-Formed Steel Framing Design for the Next Generation

Steel framing design continues to evolve with software tools like ScotStruct, which combines design precision, comprehensive load checks, and intuitive reporting into one integrated solution. By streamlining the analysis of load-bearing walls, openings, connections, and lateral systems, ScotStruct ensures that cold-formed steel framing design is not only accurate but also practical for real-world construction.

As the demand for cold-formed steel grows globally, engineers and builders can rely on ScotStruct to simplify complexity, enhance compliance, and unlock the full potential of steel framing in modern construction.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Best Steel Framing Results with Advanced Roll Forming Technology

- Blog – Complete Guide to Steel Framing Design in High Wind Zones

- Blog – Practical Guide to Web Openings in Cold-Formed Steel Framing

- Blog – A Valuable Partner in the World of Light-Gauge Steel

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Blog – Steel Framing: A Powerful Response to Thermodynamic Challenges

- Video – Steel Frame Experience 2024: Don Allen, Steel Framing Industry Association

- Video – How Scottsdale’s Roll Forming Technology and Software Support Business Growth

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.