Building in high wind zones requires precision, resilience, and confidence in structural performance. From Florida and the Bahamas to Australia, Tonga, and New Caledonia, the challenges of building in hurricane zones and building in high wind zones highlight the need for systems capable of resisting powerful winds. At Scottsdale Construction Systems, our roll forming machines are relied upon globally to produce solutions that bring strength and consistency to these environments. Through advanced cold-formed steel design and complete cold-formed steel framing systems, we help contractors and developers create buildings that stand firm against extreme weather.

Global Context: Hurricanes, Cyclones, and Extreme Winds

Although different terms are used around the world, hurricane in the Atlantic and Gulf regions, cyclone in the South Pacific and Indian Oceans, and typhoon in the Northwest Pacific, the storms themselves share similar destructive potential. The classification system is consistent: the stronger the winds, the higher the storm category. Recent global events emphasize the risks faced by our communities.

Image Source: Research Gate

Hurricane Helene in 2024 struck Florida’s Big Bend region as a Category 4 storm with winds exceeding 140 miles per hour, causing fatalities and nearly 80 billion dollars in damages. In 2025, Hurricane Erick became one of the earliest major storms ever recorded in the Eastern Pacific, while Hurricane Erin intensified to Category 5 status, producing waves over 80 feet offshore and disrupting communities along the U.S. East Coast even without landfall. In addition, a rare meteorological event in 2025 saw six simultaneous cyclones in the Southern Hemisphere, further underscoring how frequent and severe these events have become. These realities demonstrate why cold-formed steel structures fabricated by modern roll forming machines are critical for building in high wind zones worldwide.

Understanding How High Winds Damage Buildings

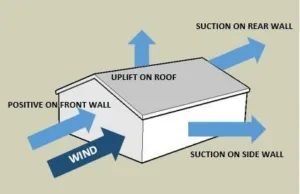

High winds damage buildings in multiple ways, and every mechanism highlights the importance of strong materials and reliable connections. Storm systems such as hurricanes and cyclones don’t simply push against walls; they create complex forces of pressure, suction, uplift, and internal pressurization, while also driving debris and rain into structures. Weak connections, poor detailing, or unprotected openings significantly increase building vulnerability. Understanding each of these mechanisms explains why traditional building methods often fail in extreme wind zones and why engineered solutions, like cold-formed steel framing systems, provide a safer alternative.

Wind Pressure & Suction

As wind flows around a building, it generates high pressure on the windward side and low pressure (suction) on the leeward side and roof. These differences in pressure can rip roofs off, collapse walls, or shatter windows. Roof edges and corners are particularly vulnerable because wind accelerates as it flows around sharp edges, amplifying suction and uplift.

Image Source: Research Gate

Uplift on Roofs

Roofs behave much like airplane wings. Fast-moving air across the top surface creates suction forces that attempt to lift the roof off the structure. If nails, screws, or truss connections are weak, the roof can detach entirely, exposing the building’s interior to further wind damage.

Windborne Debris

Strong winds often pick up objects such as branches, signs, and other materials, turning them into dangerous projectiles. These can puncture walls, break windows, or damage roofs. Once openings form, they create pathways for further structural failure.

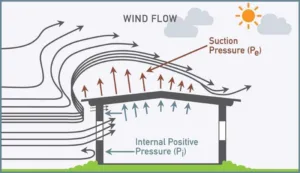

Internal Pressurization

When windows, doors, or walls are breached, wind rushes inside the structure. This trapped air increases internal pressure, pushing up on the roof and outward on the walls. Combined with external suction, this effect often results in catastrophic blowouts.

Lateral Loads

When wind strikes a building, it exerts horizontal forces known as lateral loads that push against the structure’s vertical elements. These forces create shear loads in walls, columns, and connections as the building resists sliding or overturning. Wind pressure on the windward face generates direct shear, while suction on the leeward side and uplift on the roof amplify the overall loading. If not properly accounted for in structural design, these shear forces can cause racking of walls, cracking at connections, or even structural failure. Engineers address wind-induced lateral and shear loads through bracing systems, shear walls, rigid frames, and foundation anchorage to ensure the building remains stable under high wind conditions.

Learn more about lateral force resisting systems in steel framing by reading “All You Need to Know on Strap Bracing vs. K-Bracing”.

Dynamic Forces (Fatigue & Vibration)

High winds rarely push with steady force. Instead, they gust and swirl, creating fluctuating loads that fatigue building materials and loosen fasteners or joints over time. Tall structures may also sway or resonate, leading to cracks and long-term damage.

Secondary Effects

Once the building envelope is compromised, secondary damages escalate rapidly. Wind-driven rain intrudes into insulation, electrical systems, and finishes. The initial failure of one component—such as a roof—can set off a progressive collapse, weakening the entire structure and often resulting in total loss.

Traditional building practices, weak materials such as wood and lumber, in addition to imprecise construction, leave buildings vulnerable. Whereas cold-formed steel framing systems are engineered with predictable responses, ensuring far greater resistance in extreme weather conditions.

Advantages of Cold-Formed Steel in High Wind Zones

The benefits of cold-formed steel framing in hurricane and cyclone regions are both structural and practical. One of the greatest advantages is the high strength-to-weight ratio. Because the material provides superior strength while remaining lightweight, the load on foundations is reduced while the overall stability of the structure increases. Cold-formed steel design also delivers consistency and predictability under stress. Unlike timber, which can split, warp, or fail unpredictably, cold-formed steel members perform uniformly and allow engineers to calculate performance with accuracy.

Wind resistance is significantly higher with cold-formed steel structures because mechanically fastened connections are less likely to fail than nailed or glued joints. Protective coatings ensure corrosion resistance, an essential quality in coastal or humid regions where hurricanes and cyclones strike. Precision engineering and fabrication with roll forming machines guarantee that each stud, track, and truss is manufactured to exact specifications, reducing the likelihood of weak points under extreme loads.

Learn more about Rivets vs. Screws connections by reading our article “All You Need to Know About Rivets vs. Screws”.

Faster construction times are also possible with prefabricated cold-formed steel systems, limiting the exposure of unfinished buildings to dangerous weather conditions. Beyond this, cold-formed steel framing systems allow for versatile designs, including aerodynamic roof shapes and custom bracing, making them adaptable to the unique conditions of every site.

Codes and Standards for Cold-Formed Steel Design in High Wind Zones

The design of cold-formed steel structures in hurricane and cyclone areas is guided by international building standards. The 2024 International Building Code (IBC), Section 1609: Wind Loads, provides the basis for calculating structural requirements of building components under high wind loads. The 2024 International Residential Code (IRC), Chapter 8 Roof-Ceiling Construction, Section R804: Cold-Formed Steel Roof Framing, also includes detailed provisions for residential buildings with cold-formed steel roof framing in high wind zones.

The North American Standards for Cold-Formed Steel Structural Framing, AISI S240-20, defines requirements for cold-formed steel framing systems to ensure safety and resilience. Industry guides such as Strength in the Face of Disaster: How Cold-Formed Steel Framing Keeps Buildings Safe provide further insights into best practices. Because steel is predictable, applying these codes is straightforward, and the capacity of roll forming machines to fabricate members to precise specifications ensures designs are executed without compromise.

Keeping up with building codes can be challenging, regardless of the building type or material. When it comes to building with cold-formed steel framing, there is a simpler solution.

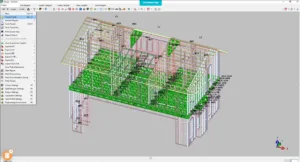

Scottsdale’s End-to-End System for High Wind Zone Construction

Scottsdale Construction Systems has developed a complete process that simplifies the complexity of building in hurricane zones and building in high wind zones. Our software suite, including ScotSteel and ScotStruct, automatically applies the requirements of international codes, generating reports that confirm compliance and highlight the performance of the proposed structure. Once a design has passed, the model is exported to our roll forming machines via ScotRF. At this stage, every cut, notch, punch, and swage is fabricated with precision, ensuring that the finished members meet the demands of cold-formed steel design for high wind environments.

Learn why ScotSteel is the best steel framing design software in the industry by reading “Best Steel Framing Results with Advanced Roll Forming Technology”.

The result is a complete cold-formed steel framing system that is ready for assembly on-site. From engineering verification to fabrication and final installation, Scottsdale offers not just machinery but a fully integrated roll forming ecosystem of tools and support services. Our engineers assist customers in design, while our Knowledge Base provides training materials, design guides, and practical resources. This holistic approach ensures that every cold-formed steel structure produced with our roll forming technology is optimized for the challenges of hurricane and cyclone conditions.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Global Applications of Roll Forming in High Wind Zones

The real-world impact of Scottsdale’s solutions can be seen across the globe. In Florida and the Bahamas, cold-formed steel framing systems provide peace of mind to communities facing annual hurricane threats. In Australia, where building codes mandate cyclone-resilient structures, cold-formed steel design is central to compliance and safety. In New Caledonia and other island nations, where material shipping costs are high, lightweight cold-formed steel structures fabricated with precision roll forming machines offer both durability and efficiency. These projects demonstrate that whether one is building in high wind zones of the South Pacific or building in hurricane zones along the Atlantic, the combination of engineering, design, and fabrication provided by Scottsdale Construction Systems creates reliable results.

The Future of Building in Hurricane and Cyclone Regions

As hurricanes and cyclones increase in frequency and intensity, the need for resilient construction methods becomes more urgent. The vulnerabilities of traditional materials are clear, but the advantages of cold-formed steel framing leave no doubt about the future direction of the construction industry. By investing in roll forming machines and embracing complete cold-formed steel framing systems, builders and developers ensure that structures resist uplift, debris impact, and internal pressurization. Scottsdale’s integrated approach, spanning software, fabrication, and engineering support, simplifies the entire process of building in high wind zones.

The storms of the future will be stronger, but through cold-formed steel design and advanced roll forming technology, communities can be safer and more resilient. From Florida to Fiji, and from the Bahamas to New Caledonia, Scottsdale continues to help customers meet the demands of the harshest environments with cold-formed steel structures that protect lives, preserve investments, and deliver lasting confidence.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Blog – How Steel Framing Delivers a Safer Ski Resort in Argentina

- Blog – Steel Homes: An Affordable Solution to the Housing Crisis

- Blog – Grow Your Competitive Edge with In-House CFS Fabrication

- Video – Advantages of Riveted Steel Framing with Scottsdale’s Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.