Cold-formed steel framing has become a trusted solution for building in some of the world’s most challenging environments. In high-seismic regions, where earthquakes generate extreme lateral forces, the reliability and predictability of cold-formed steel members make them a preferred choice over traditional building materials. The science of steel framing design for high-seismic zones has evolved through decades of research, testing, and the development of building codes and standards that guide safe construction practices.

This article explores why cold-formed steel framing is increasingly specified in seismic zones, the standards that govern its design, the lateral force resisting systems available, emerging innovations, and how advanced roll forming of steel framing is supporting safer, more resilient buildings.

Where Are High-Seismic Regions?

High-seismic regions are those areas of the world where the probability of strong ground shaking from earthquakes is significant. In North America, this includes the western United States, such as California, Oregon, and Washington, along with parts of Alaska. Across Latin America, countries like Chile, Mexico, and Peru frequently experience earthquakes due to their position along the Pacific Ring of Fire. In the Asia-Pacific region, Japan, New Zealand, the Philippines, and Indonesia are all highly active tectonic zones. Other parts of the world, including sections of the Middle East, Southern Europe, and South Asia, also face elevated seismic risks.

In all of these regions, steel framing design must account for seismic loads in addition to wind, snow, and gravity loads. The inherent properties of cold-formed steel members make them well-suited to deliver the strength, ductility, and predictability needed to withstand such demanding conditions.

ASCE recently launched the ASCE Hazard Tool, allowing designers and engineers to look up key design parameters as a free resource. This resource connects designers to hazard data for eight environmental hazards, including seismic, wind, tornado, and more.

Why Cold-Formed Steel Framing is Preferred in High-Seismic Regions

Cold-formed steel framing offers several characteristics that explain its growing role in seismic-resistant construction. Its high strength-to-weight ratio means that buildings framed with cold-formed steel members are lighter, which reduces the magnitude of seismic forces transmitted to the foundation. Unlike other materials that may vary in quality, cold-formed steel members are manufactured with precision through roll forming of steel framing, ensuring consistency in thickness, geometry, and mechanical properties.

Another reason for its popularity is ductility. In seismic events, ductility allows structures to absorb and dissipate energy, preventing sudden or brittle failure. Beyond seismic resilience, cold-formed steel framing is non-combustible, durable against environmental deterioration, and resistant to pests, which contributes to long-term safety. Finally, the ease of penalization and modular construction allows for rapid assembly, which is especially valuable in areas where rebuilding after an earthquake must happen quickly. All of these advantages align directly with seismic design objectives such as ensuring life safety, maintaining structural stability, and supporting post-event recovery.

Building Codes and Standards for Steel Framing Design in High-Seismic Regions

Designing cold-formed steel framing in high-seismic zones requires adherence to well-established building codes and standards. The primary reference is AISI S400-20, the North American Standard for Seismic Design of Cold-Formed Steel Structural Systems, which specifically addresses cold-formed steel members and connections in seismic force-resisting systems. This standard works in conjunction with AISI S100, the North American Specification for the Design of Cold-Formed Steel Structural Members, which provides the foundation for structural design across multiple loading conditions.

In addition, design professionals must look to guidelines developed by organizations such as FEMA and NIST, which support seismic safety and performance-based engineering practices. The International Building Code (IBC) and ASCE 7 go hand in hand, establishing seismic design categories and load requirements that govern structural design. Collectively, these documents ensure that lateral force resisting systems in steel framing achieve the performance necessary for life safety and structural resilience.

For more information, review NEHERP Seismic Design Technical Brief No. 12 on “Seismic Design of Cold-Formed Steel Lateral Load-Resisting Systems”.

Lateral Force Resisting System Options in Steel Framing

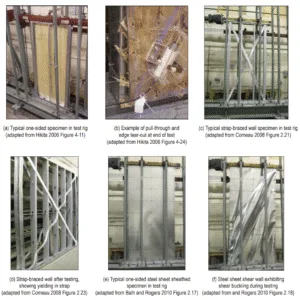

Cold-formed steel framing design in seismic regions depends heavily on effective lateral force resisting systems that can maintain stability during strong earthquakes. Shear walls with different sheathing material, strap-braced walls, and moment frames are the notable lateral force resisting systems currently defined in the building code for cold-formed steel structures.

Image Source: NEHERP Seismic Design Technical Brief on “Seismic Design of Cold-Formed Steel Lateral Load-Resisting Systems”

Among the most reliable solutions are shear walls sheathed with steel sheet panels, which provide superior ductility and energy dissipation under cyclic seismic loads. Unlike wood-based sheathing, steel sheet panels deliver predictable performance, higher strength, and improved durability, making them particularly well-suited for high-seismic applications where repeated loading is expected.

Another proven option is the use of strap-braced shear wall systems. These systems employ diagonal steel straps connected to cold-formed steel framing members, creating an efficient means of resisting lateral forces. Strap bracing takes advantage of steel’s inherent strength and flexibility, allowing buildings to absorb and redistribute seismic energy without sudden failure. For many engineers, strap-braced walls strike a balance between simplicity of construction, seismic reliability, and cost effectiveness.

While other lateral force resisting systems, such as hybrid sheathing combinations, gypsum-sheathed shear walls, or moment frames, may be appropriate in certain contexts, the most robust and widely favored approaches in high-seismic regions remain shear walls sheathed with steel sheet panels and strap-braced wall systems. These methods not only maximize the inherent benefits of cold-formed steel members but also give engineers confidence that their steel framing design will meet the demanding requirements of seismic safety and performance.

Image Source: NEHERP Seismic Design Technical Brief on “Seismic Design of Cold-Formed Steel Lateral Load-Resisting Systems”

The referenced study was conducted in 2016, with some test results dating back to the early 2000s. At that time, the steel sheathing used in steel-sheathed shear walls and strap-braced shear walls was primarily Grade 33 ksi material. It is important to note that today the steel framing industry more commonly utilizes Grade 50 ksi material. The higher strength of Grade 50 ksi steel is expected to provide improved shear wall performance compared to the earlier Grade 33 ksi material.

What is the Response Modification Factor, R, in Seismic Design?

The Response Modification Factor (R), or R-factor, is a crucial concept in seismic design that defines a structure’s ability to deform inelastically and dissipate seismic energy. The R-factor reduces the seismic design forces on a structure by taking into account a series of factors. The R-factor is a dimensionless number that reflects the ductility, overstrength, and energy dissipation capacity of a structural system.

R-factor is defined as the ratio of the maximum seismic force that a structure would experience if it were to remain elastic during an earthquake to the design seismic force used in the seismic design of the structure. By applying the R-factor, designers and engineers can design structures to withstand earthquakes without collapsing, even if they undergo inelastic deformation. This approach has been adopted to ensure life safety and cost-effective performance in high-seismic regions.

A high R-factor indicates that the structure is designed to withstand significant inelastic deformation, which is important for systems with higher ductility and detailing requirements. A low R-factor suggests that the structure is designed to remain elastic during seismic activity, which is less critical for systems with lower ductility.

ASCE 7 specifies a R-factor of 6.5 for cold-formed steel load-bearing shear walls using wood structural panels or steel sheet sheathing. R-factor of 4 is defined for cold-formed steel load-bearing strap-braced walls. Strap-braced shear walls can be designed with a wide range of available strength by varying the strap width, thickness, and yield point. Anchorage forces for trap-braced shear walls often limit the total available strength and aspect ratio.

At Scottsdale Construction Systems, we have performed our own set of tests on cold-formed steel lateral force resisting systems. A summary of our results can be found at “All You Need to Know on Strap-Bracing vs. K-Bracing”.

New Solutions and Innovations for Steel Framing in High-Seismic Regions

Recent years have brought forward new innovations that strengthen the role of cold-formed steel framing in seismic construction. One of the most significant research initiatives is the CFS-NEES project, which has advanced knowledge of seismic performance through extensive experimental work. Researchers have conducted shear wall testing to better understand how wall assemblies behave under earthquake loads, cyclic testing of cold-formed steel members to characterize repeated loading behavior, and full-scale shake table experiments that replicate the effects of earthquakes on entire steel-framed buildings.

Image Source: Johns Hopkins, Department of Civil & Systems Engineering

Read more about the CFS-NEES Project at “Seismic Response and Engineering of Cold-Formed Steel Framed Buildings”.

These efforts have laid the foundation for performance-based design approaches, which go beyond prescriptive rules to consider how buildings actually respond to seismic forces. The use of nonlinear modeling has also become more sophisticated, enabling engineers to simulate earthquake effects with greater accuracy. Together, these innovations are providing the necessary tools to design cold-formed steel framing that is safer, more efficient, and better suited to the realities of seismic zones.

Scottsdale Construction Systems: Providing Solutions for High-Seismic Regions

Scottsdale Construction Systems has established itself as a global leader in delivering steel framing solutions that perform under seismic conditions. At the heart of this capability is the company’s roll forming of steel framing, which produces precise and consistent cold-formed steel members essential for seismic performance. Each profile is manufactured to exact tolerances, ensuring reliable behavior when used in lateral force resisting systems in steel framing.

Roll forming solutions for fabricating lateral force resisting systems are available through both the Scotpanel and KFS Framemaker series. For smaller-scale projects, such as residential or low-rise commercial buildings up to five stories, the Scotpanel roll forming machine provides an efficient and reliable option for producing steel framing and lateral force resisting systems. For larger developments, including mid-rise commercial buildings up to ten stories, as well as industrial and institutional facilities, the KFS Framemaker roll forming machines deliver the capacity, strength, and flexibility required to meet more demanding structural and seismic design requirements.

Our Scottsdale roll forming technology has been successfully deployed in over 100 countries, including some of the most earthquake-prone regions in the world, such as Haiti, Pakistan, China, Turkey, and New Zealand.

Scottsdale complements its machinery with advanced software platforms such as ScotSteel and ScotStruct, which allow engineers to design seismic-resilient structures, model different resisting systems, check compliance with standards like AISI S400-20, and generate detailed engineering reports. Because Scottsdale systems are used in countries with some of the strictest seismic codes, including New Zealand, Japan, Chile, and the western United States, the technology has been proven in practice. In addition, Scottsdale provides training, support, and global expertise to help builders and engineers achieve best practices in steel framing design for high-seismic regions.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Strengthening Communities with Cold-Formed Steel Framing Design

Cold-formed steel framing offers unmatched advantages in seismic construction, combining lightweight efficiency with reliable strength and ductility. Supported by rigorous codes and standards, steel framing design can incorporate a range of lateral force resisting systems that provide stability during earthquakes. Innovations such as full-scale shake table testing and performance-based design are further refining how cold-formed steel members are applied in seismic engineering.

With precision roll forming of steel framing and advanced software integration, Scottsdale Construction Systems enables builders worldwide to deliver projects that meet the demands of high-seismic environments. As construction continues to adapt to seismic risks, cold-formed steel framing stands out as a material and system capable of protecting lives, ensuring resilience, and shaping safer communities.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Complete Guide to Steel Framing Design in High Wind Zones

- Blog – The Latest in Fire Performance of Cold-Formed Steel Structures

- Blog – How Steel Framing Delivered a Safer Ski Resort in Argentina

- Blog – Steel Framing: A Powerful Response to Thermodynamic Challenges

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Video – STALART: How to Create Construction Innovation with Roll Forming Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.