ScotRF is a powerful roll forming and production management software designed to integrate seamlessly with ScotSteel and Scottsdale roll forming machines for efficient and precise steel framing production. By connecting directly to roll forming machines, ScotRF transforms design data into fabrication-ready instructions for cutting, notching, punching, swaging, and more. This technology supports steel framing fabrication at scale while also enabling printing steel framing for accurate assembly. Whether you’re working on residential projects or complex commercial structures, ScotRF ensures unmatched efficiency, flexibility, and control in every stage of the steel framing process.

Real-Time Controls in Steel Framing Production

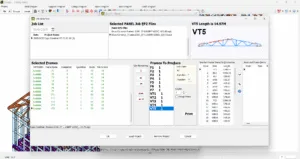

At its core, ScotRF acts as the digital link between design and manufacturing. The software continuously communicates precise cut lengths, hole placements, and swaging instructions to roll forming machines, ensuring that every member matches the intended design. Features such as real-time member tracking and emergency alteration tools allow users to optimize steel framing production without stopping the line. For contractors and builders, this reduces downtime, material waste, and errors during steel framing fabrication.

Production Optimization for Roll Forming Efficiency

ScotRF is built to streamline operations for maximum throughput. By sequencing components in a build-ready order, the system optimizes steel framing production workflows. When user-defined adjustments are needed, ScotRF offers override capabilities to reorder the production sequence. Smart steel coil sequencing also minimizes changes on the roll forming machines, saving both time and resources. This level of automation reflects the future of printing steel framing, where production data becomes the backbone of efficient steel framing fabrication.

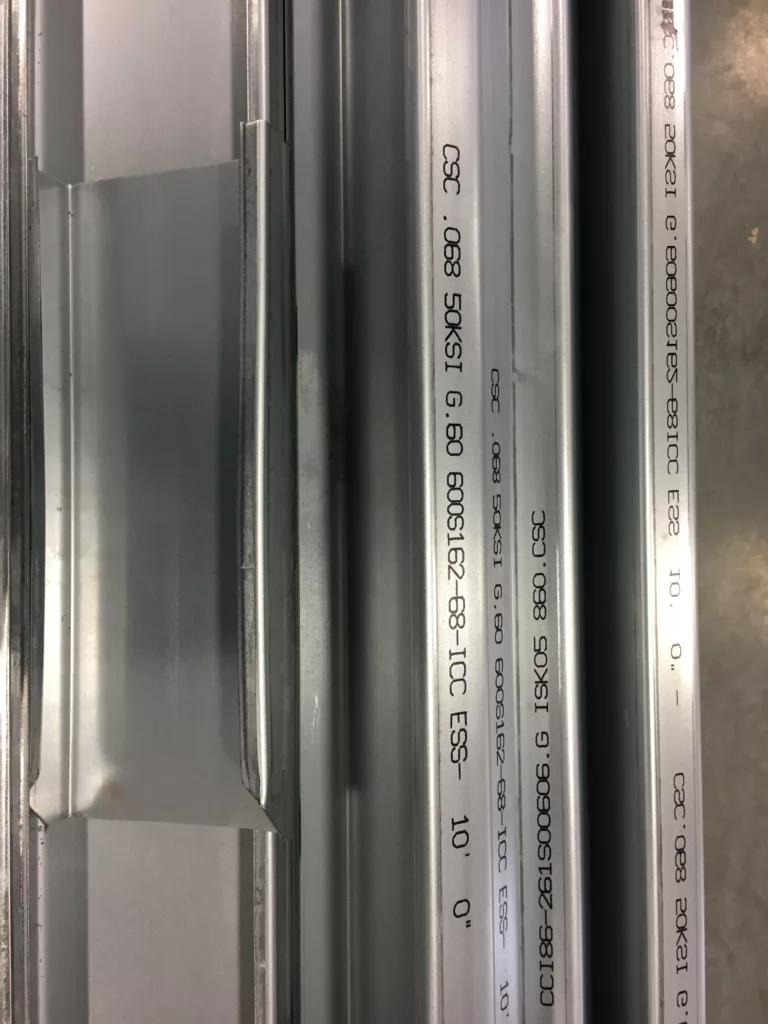

Printing on Steel for Precision Steel Framing Assembly

One of the most favored features of ScotRF is its ability to support printing directly on steel framing members when inkjet printers are integrated into roll forming machines. Labels, codes, or any custom marks can be applied in real time, simplifying branding and assembly. For fabricators, this streamlines the manufacturing process, ensuring every member is accurately produced and positioned in its precise location. For builders, this means faster installation of walls, trusses, floors, and roofs, as each component is clearly identified. By combining digital control with physical production, ScotRF enhances the precision and clarity of steel framing fabrication.

Diagnostics and Calibration During Steel Framing Fabrication

Downtime is a critical concern in any production process, including steel framing production. ScotRF includes machine diagnostics and live calibration tools that function even during operation. This ensures roll forming machines are performing at peak efficiency without requiring stoppages. By reducing interruptions and material waste, ScotRF enables continuous steel framing fabrication, delivering projects faster while maintaining strict quality standards. For contractors, this translates into higher margins and consistent reliability.

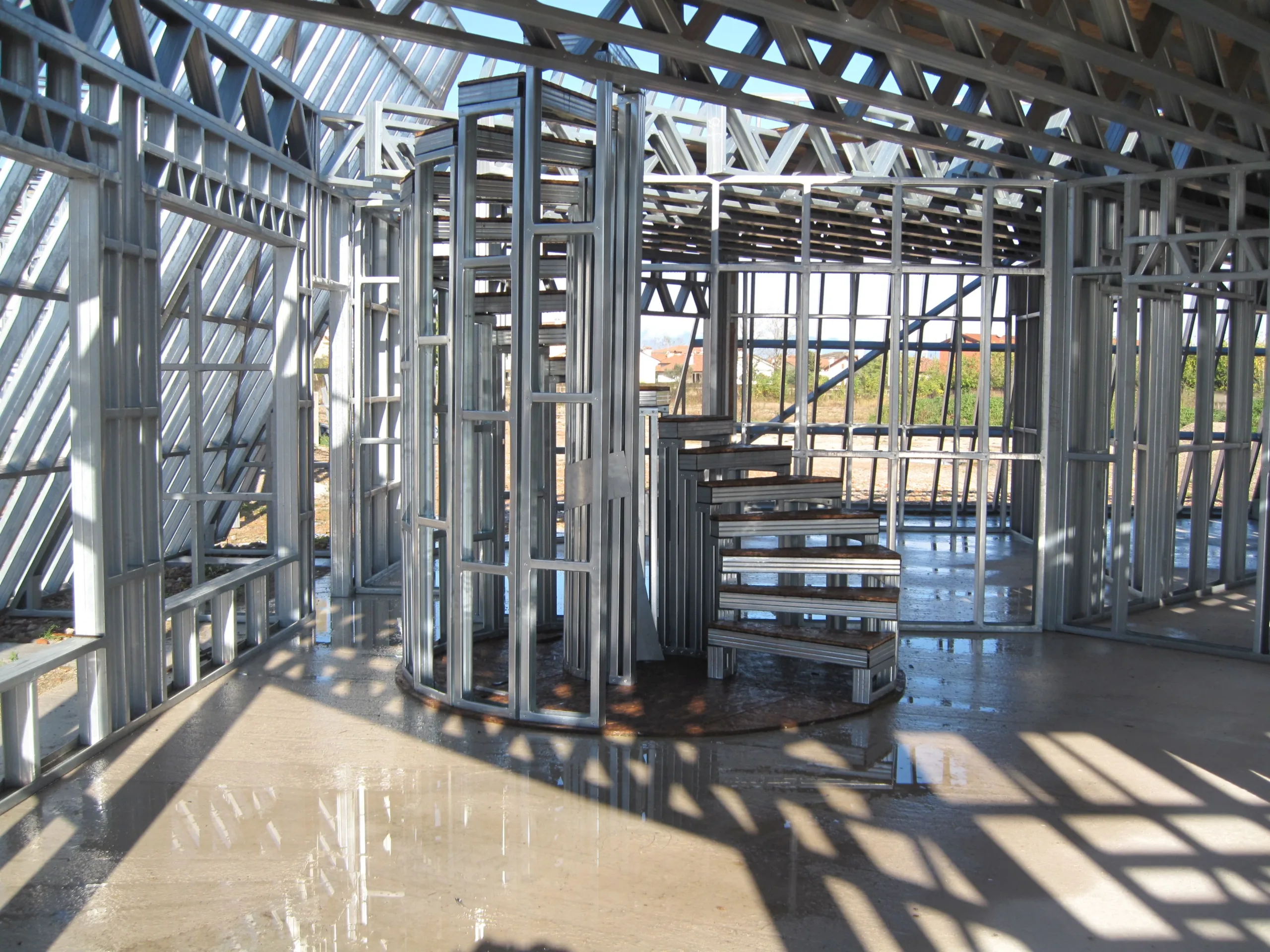

Scalability in Roll Forming and Steel Framing

Whether you are fabricating simple residential units or large-scale commercial facilities, ScotRF adapts to any project scale. From single-story steel homes to multi-level complexes, the software optimizes steel framing production to match the design requirements. With support for walls, floors, ceilings, and roof systems, ScotRF works across every structural element of a building. Beyond construction, printing steel framing capabilities extend its applications to solar framing, industrial racks, and even custom sculptures. This flexibility demonstrates how ScotRF pushes the boundaries of steel framing fabrication.

Reporting and Planning in Steel Framing Production

Detailed and summary reports are built into ScotRF, offering insights into both real-time and historical performance. Material usage summaries, optimization reports, and project-level outputs make inventory planning simple. By analyzing these reports, contractors can refine steel framing production schedules, manage material flow more effectively, and identify opportunities for efficiency. Combined with the control of roll forming machines, this data-driven approach keeps every aspect of steel framing fabrication transparent and predictable.

The Future of Steel Framing Fabrication with Roll Forming Machines

ScotRF represents a leap forward in construction technology. By linking roll forming precision with smart production management, it transforms how steel framing fabrication is executed across the globe. From enabling printing on steel framing for accurate on-site and off-site assembly to real-time diagnostics that maximize machine uptime, ScotRF empowers builders to deliver stronger, faster, and more efficient projects. In today’s competitive construction market, embracing this software ensures your steel framing production stays ahead of the curve while leveraging the full potential of advanced roll forming machines.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Best Steel Framing Results with Advanced Roll Forming Technology

- Blog – 7 Reasons ScotStruct Makes Complete Steel Framing Design Easy

- Blog – ISG Frames Delivers an Epic Project with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – A Better Inexpensive Ergonomic Steel Framing Fabrication Process

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Blog – How to Launch a Successful Steel Framing Business

- Video – How to Create Construction Innovation with Roll Forming Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.