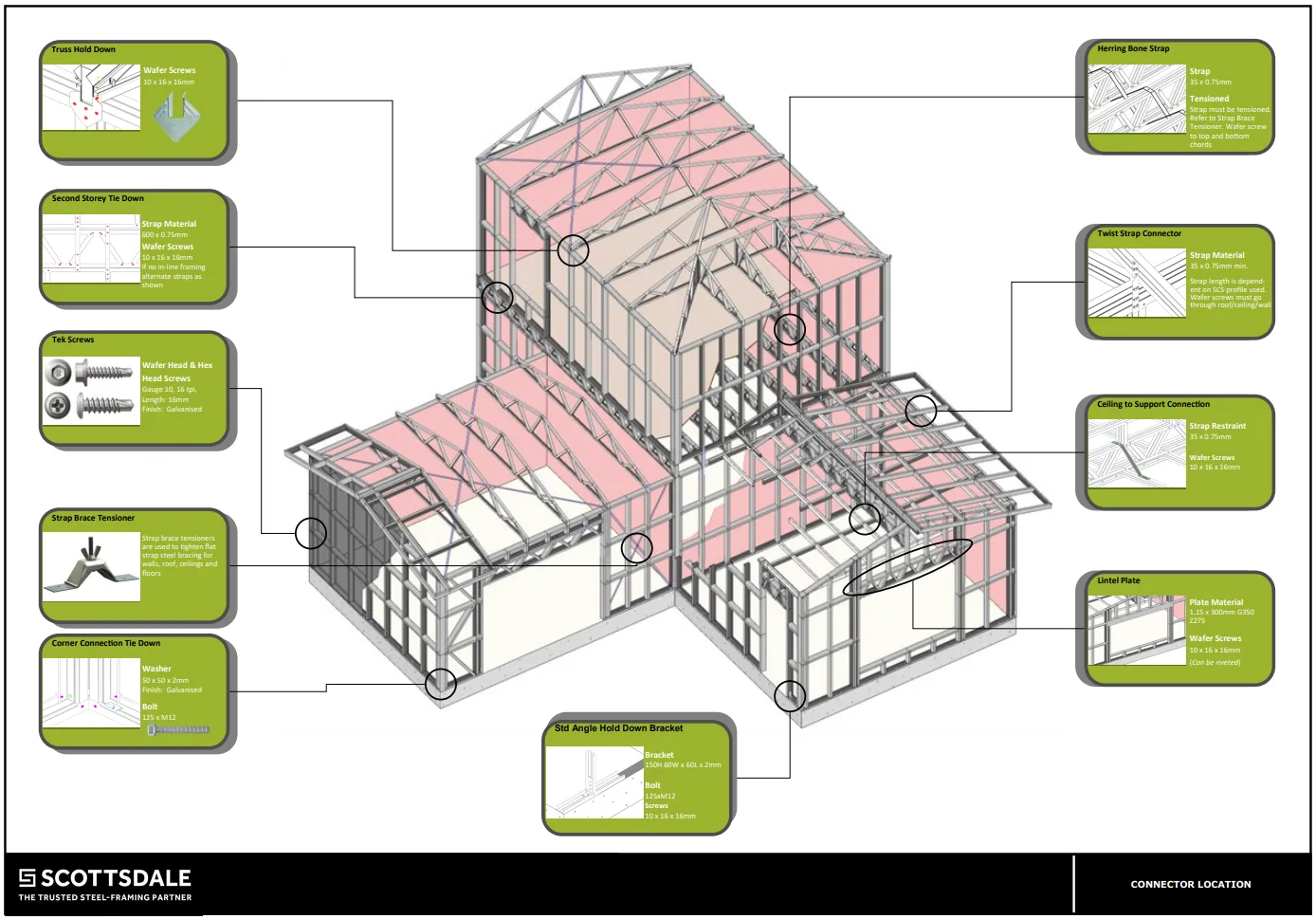

Why do connections matter in steel-framed buildings? When it comes to steel framing, the performance of a steel-framed building depends heavily on the quality and detailing of its connections. Every joint, strap, plate, or screw contributes to the structural integrity of the system. In modern cold-formed steel framing, precision design ensures that every connection between cold-formed steel members performs as intended. Whether it is a strap brace, tie-down, or specialized fastener, these steel framing connections form the backbone of safe, resilient, and efficient buildings. This article explores the most common types of cold-formed steel connections, their functions, and how they integrate into the framework of a steel-framed structure.

Design and Engineering in Steel Framing: Understanding Load Paths

In cold-formed steel construction, the success of a structure depends on more than just the strength of the individual cold-formed steel members; it relies on how effectively loads are transferred from one element to the next, all the way down to the foundation. This is where design and engineering play a critical role.

Every connection, from roof trusses to wall studs, and from floors to tie-downs, must be detailed to ensure a continuous and predictable load path. Understanding load paths means recognizing how gravity, wind, and seismic forces flow through the steel framing connections, preventing weaknesses or stress concentrations that could compromise the performance of the entire steel-framed building. Proper engineering ensures that forces move seamlessly through each member and connection, safeguarding structural integrity and long-term durability.

Truss Hold-Downs in Steel Framing

Lastly, truss hold-downs connect roof trusses or floor trusses to primary framing members. These cold-formed steel connections come in many types, all designed to meet specific project loads. Without them, steel-framed buildings would be vulnerable to uplift, especially under high wind conditions. Correct detailing ensures that steel framing connections transfer forces efficiently into the main structure, maximizing the performance of the cold-formed steel framing system.

Second-Story Tie-Down in Steel-Framed Buildings

In a steel-framed building, second-story tie-downs are essential steel framing connections that link the floor of the story above to the ceiling of the story below while also tying into the joist and truss system. In cold-formed steel framing, these connections typically use strap material measuring 600 mm by 0.75 mm, fastened to cold-formed steel members with screws. The number and spacing of screws are project-specific and must be engineered to meet the required loads.

In cases where the framing of the upper and lower floors does not align, alternating straps (as seen in the image) provide a reliable solution. These cold-formed steel connections ensure structural continuity, creating a predictable load path and enhancing the overall stability of the steel-framed building.

Tek Screws for Cold-Formed Steel Connections

In cold-formed steel framing, the method of connection depends on the type of system being fabricated. When using Scottsdale roll forming machines, cold-formed steel wall panels are connected with rivets, ensuring durable steel framing connections. For truss systems fabricated by Scottruss roll forming machines, the cold-formed steel members are connected with bolts to withstand higher loads.

Across all systems, steel-framed buildings rely on Tek-screws, most commonly wafer head or hex head screws, as the primary fasteners for general assembly. These cold-formed steel connections are usually 10-gauge, 16 mm long, and galvanized, providing the strength and corrosion resistance necessary for long-term performance of the structure.

Strap Brace Tensioner in Cold-Formed Steel Framing

A strap brace tensioner is critical in walls, roofs, ceilings, and floor assemblies. In cold-formed steel framing, these tensioners tighten flat strap braces in X-bracing systems, forming one of the most effective lateral force-resisting systems. Strap brace tensioners are critical to the overall performance of the steel-framed building, especially under wind and seismic loads.

Learn more about bracing options by reading our article: “Best Practices and Advice for Bracing Using Steel Framing Machines”.

Corner Connection Tie-Down in Steel Framing

Corners of a steel-framed building are high-stress locations that require detailing. The corner connection tie-down uses galvanized bolts and washers to lock two wall panels together. These steel framing connections transfer loads effectively and prevent separation during seismic or wind events. With precise installation, cold-formed steel members remain secure, reinforcing the overall strength of the cold-formed steel system.

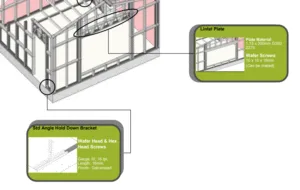

Stud Angle Hold-Down Brackets in Steel Framing

Door openings in steel-framed buildings are common stress points. Stud angle hold-down brackets reinforce these locations by securing studs around openings. These steel framing connections are typically installed with wafer head or hex head screws and provide resistance against both vertical and lateral loads. Proper installation ensures cold-formed steel members remain aligned and openings do not weaken the cold-formed steel framing system.

Lintel Plating for Steel Framing Connections

Openings in walls, such as doors and windows, require additional reinforcement. Lintels are designed to support the weight of the wall or roof above the opening and distribute that load evenly across the top of the opening. The flat plate must span the full width of the lintel and is secured with wafer screws. This method ensures that cold-formed steel members remain in compression and that cold-formed steel connections at openings do not become weak points in the system. For double top-chord lintels, wider plates are required, making this connection essential for the structural integrity of the building.

Learn more about designing lintels by reading our article: “How to Design Cold-Formed Steel Double Top Chord Lintels”.

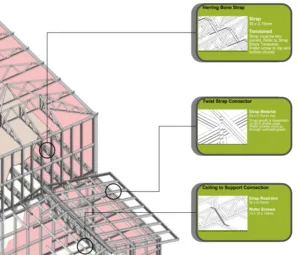

Ceiling-to-Support Connection in Steel-Framed Buildings

One of the less visible but highly important steel framing connections is the ceiling-to-support strap. This strap connects the ceiling to the truss or joist system above using wafer screws. In cold-formed steel framing, the ceiling-to-support connection prevents deflection, improves fire performance, and ensures the durability of cold-formed steel members in service.

Twist Strap Connectors for Cold-Formed Steel Members

Twist strap connectors allow cold-formed steel connections to run from the top of the wall panels up to the ceiling or roof members. These connectors are essential in creating continuous load paths in framing, making sure that forces move smoothly from one set of cold-formed steel members to another. The strap length varies depending on the design and cold-formed steel members used.

Herringbone Strap for Cold-Formed Steel Connections

The herringbone strap is another specialized connector used in cold-formed steel framing. Positioned between trusses or joists, this strap prevents members from shifting during loading by connecting the strap at the top and bottom chords of each truss or joist with wafer screws. By tensioning the strap with brace tensioners, engineers guarantee that steel framing connections hold the roof or floor system firmly in place. As a result, cold-formed steel members remain aligned, preventing distortion and enhancing the stiffness of the steel-framed building.

The Role of Connections in Steel-Framed Buildings

From strap brace tensioners to Tek screws, every component in the framing matters. A steel-framed building is only as strong as its steel framing connections. By integrating well-designed cold-formed steel connections, engineers ensure that cold-formed steel members perform reliably across the life of the structure. The precision and adaptability of cold-formed steel framing continue to make it one of the most effective construction methods for modern projects.

More information on cold-formed steel framing connections can be found on Scottsdale’s Knowledge Base platform.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – New Solution for Fascia Bracket Installation in Cold-Formed Steel

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Blog – All You Need to Know About Rivets vs. Screws

- Blog – Key Reasons for Staggering Noggings in Cold-Formed Steel Wall Panels

- Blog – Cold-Formed Steel Framing in High-Seismic Regions: All You Need to Know

- Blog – Complete Guide to Steel Framing in High Wind Zones

- Video – Building Better Steel-Framed Tiny Homes with Roll Forming Technology

- Video – Beautiful Blue Steel Frames Made with Scottsdale’s Advanced Roll Formers

- Video – Fast and Easy Riveting in Cold-Formed Steel Framing

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.