When designing and constructing with cold-formed steel material using advanced steel framing machines, the integration of effective lateral force resisting systems is essential for the long-term performance of the steel framing structure. Bracing methods such as X-bracing and K-bracing are amongst the most commonly used steel framing bracing options, and each requires careful detailing and execution. With today’s advanced roll forming technology, builders can fabricate precise members that ensure stability, strength, and efficiency across every project.

Cold-Formed Steel Lateral Force Resisting Systems

The use of cold-formed steel has expanded rapidly due to its precision, strength, and adaptability. One of the most critical considerations in steel framing design is how a structure will resist seismic, wind, or other horizontal forces. These loads act laterally, and without proper lateral force resisting systems, the walls may rack, twist, or move out of alignment over time.

Bracing, whether X-bracing or K-bracing, forms the backbone of every steel framing system. Each bracing system has its place, and the decision depends on location, project design, available materials, architectural plans, and the wall layout.

X-Bracing in Cold-Formed Steel Structures

X-bracing is widely regarded as the preferred solution in steel framing bracing. It provides superior performance by distributing lateral loads evenly across walls, reducing localized failures, and improving resilience under seismic or wind pressures.

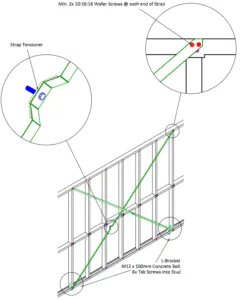

X-bracing requires planning, and builders must order steel sheets and tensioners ahead of time to ensure timely installation. Tensioners must be installed properly for the X-bracing to resist lateral loads effectively. As X-bracing requires an operating range between 30 and 60 degrees, coordination is key to avoiding conflicts with doors, windows, or wall terminations. When operating space is limited, K-bracing is an ideal lateral force resisting option. The overall cost and structural performance benefits of X-bracing make it the primary choice for most cold-formed steel projects.

K-Bracing in Cold-Formed Steel Structures

When space is limited or when steel sheets have not been ordered in time, k-bracing becomes a practical alternative. K-bracing can be fabricated using the same roll forming technology as the rest of the structure. This makes it easier for builders to adapt quickly while maintaining structural stability.

K-bracing comes with its own design requirements. To function effectively as a lateral force resisting system, the brace must be properly anchored to the foundation. Hold downs or anchors must be ordered in advance and correctly installed. Each stud connected to the K-bracing should also be anchored, ensuring that forces transfer correctly from the wall into the foundation.

Bracing Across Cold-Formed Steel Structures

Beyond walls, bracing is also critical in roof trusses, ceiling panels, and roof panels. Steel sheets for steel framing bracing need to be ordered ahead of time, and seated connections must be carefully detailed.

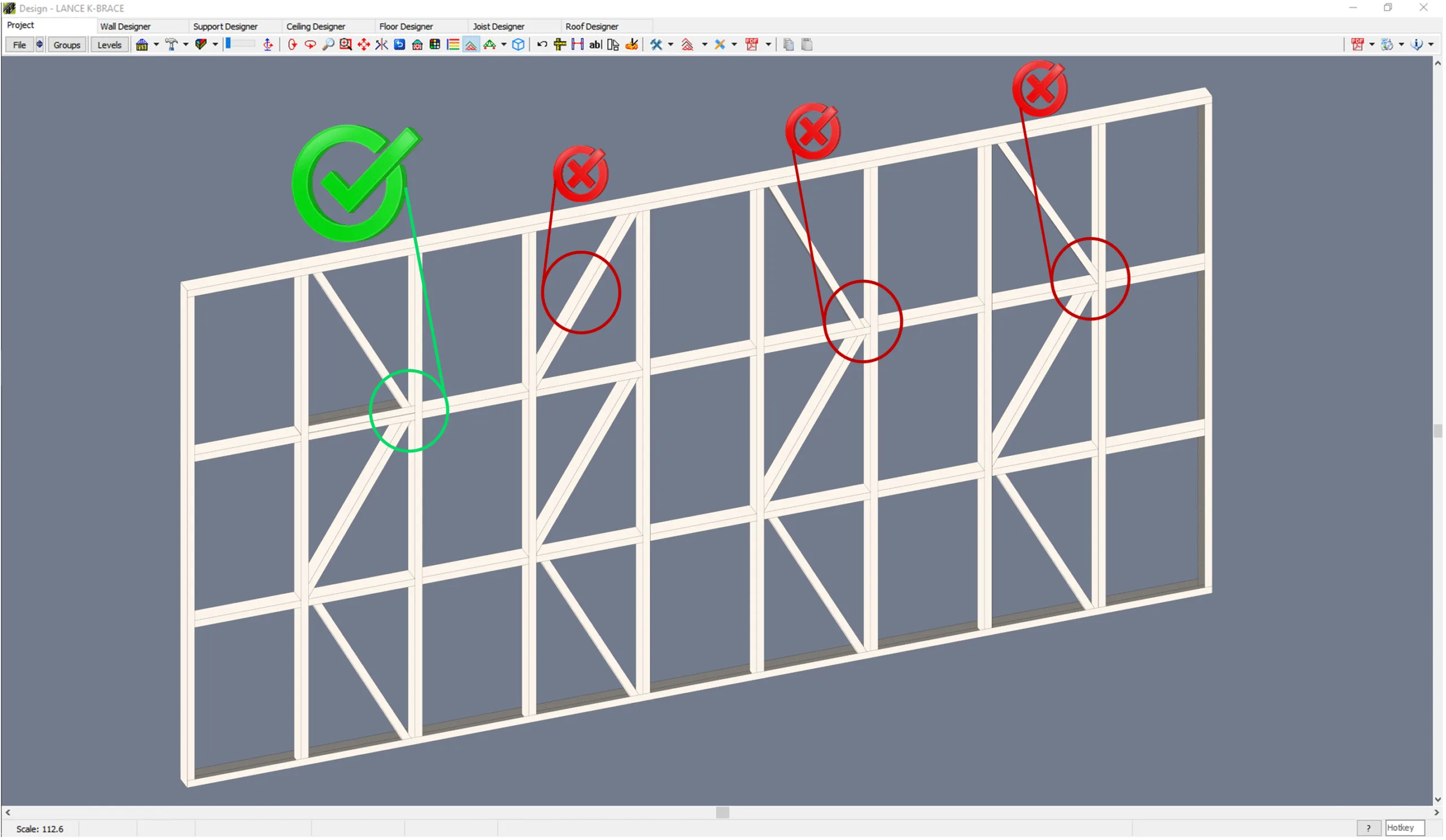

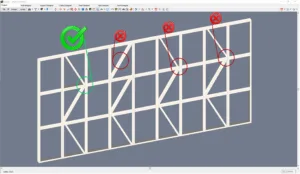

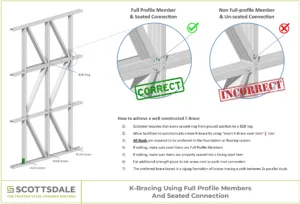

With advanced steel framing machines, builders can also automate parts of this process. For instance, software like ScotSteel has a built-in functionality for designers to automatically insert a K-bracing member by selecting the “Insert a K-Brace Steel Item” tool. The key is to ensure the brace is generated as a full-profile member. This can be achieved by adding a second nog and making it a back-to-back nog to allow for proper seated connection and prevent the K-bracing from becoming a non-full profile, therefore causing a weak point in the structure. Such integration between software and steel framing machines improves the structure’s performance and speeds up fabrication.

Roll Forming of Bracing Systems

Modern roll forming has transformed how builders fabricate cold-formed steel components. Instead of relying on stock members, today’s steel framing machines can produce every piece to exact specifications. This precision extends to K-bracing, lintels, and noggings, ensuring that each member fits seamlessly into the steel framing system.

By combining roll forming technology with careful design of lateral force resisting systems, builders can reduce waste, cut costs, and deliver stronger, more reliable buildings. Whether using X-bracing or K-bracing, the integration of advanced machines, software, and structural engineering ensures consistency across projects.

Best Practices for Steel Framing Bracing

For effective steel framing bracing, builders should follow these key design and fabrication practices:

- For X-bracing, ensure sheets and tensioners are ordered ahead of time.

- Substitute with K-bracing only when space or logistics require it.

- For K-bracing, generate a full-profile member by adding a second nog and making it a back-to-back nog.

- Always validate design changes when switching from one system to another to ensure the lateral force resisting system meets the project’s load requirements.

- Anchor lateral force resisting systems properly to the foundation.

- Use steel framing machines and roll forming technology to fabricate precise, reliable bracing members.

More design, detailing, fabrication, and construction tips can be found on Scottsdale’s Knowledge Base platform.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Steel Framing Machines Enable Stronger Bracing Systems

Both X-bracing and K-bracing play essential roles in modern steel framing. While X-bracing often provides the best structural performance, K-bracing offers flexibility when design or logistics limit other options. With advanced steel framing machines and roll forming, builders can produce precise cold-formed steel components that strengthen every part of a building. By combining thoughtful design with technology-driven fabrication, steel framing bracing becomes a reliable solution for resisting lateral forces and ensuring buildings remain safe, durable, and aligned.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Key Reasons for Staggering Noggings in Cold-Formed Steel Wall Panels

- Blog – How to Design Cold-Formed Steel Double Top Chord Lintels

- Blog – New Solution for Fascia Bracket Installation in Cold-Formed Steel

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – A Better Path Toward Sustainability with Roll Forming Technology

- Blog – Best Steel Framing Results with Advanced Roll Forming Technology

- Video – How Scottsdale’s Roll Forming Technology and Software Support Business Growth

- Video – The Ultimate Home of the World’s Best Roll Forming Machines

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.