The Opal Aged Care project in Clyde North, Victoria, Australia, demonstrates how cold-formed steel framing, roll forming, and advanced steel framing machines work together to deliver large-scale, modern, and sustainable buildings. By combining roll forming technology with precision design software, ISG Frames and APM Group successfully delivered complex cold-formed steel wall panels, custom cold-formed steel trusses, and structural solutions for one of Melbourne’s largest residential aged care facilities. This project highlights how steel framed buildings provide strength, adaptability, and efficiency while maintaining the welcoming environments required for our communities.

Project Overview: Steel Framed Buildings for Aged Care Facilities

Opal HealthCare is one of Australia’s largest aged care providers, operating more than 140 facilities nationwide. For the Clyde North project, the project required a three-level, 3,500-square-metre structure featuring 160 bedrooms, lounges, dining areas, kitchens, social spaces, and even a gym. The design vision demanded a balance between durability and warmth, exactly the type of challenge that steel framed buildings address through their versatility.

Engineering Challenges Met with Steel Framing and Roll Forming Technology

One of the most significant challenges on this project was that all internal walls were non-load-bearing. As a result, every cold-formed steel truss had to span freely across large distances, with some extending up to 21 meters. This required detailed engineering and precision fabrication. The solution lay in leveraging steel framing machines and advanced roll forming technology, which enabled ISG Frames to create long-span trusses without compromising on performance, quality, or consistency.

By relying on Scottsdale’s integrated system, the engineering team modeled cold-formed steel trusses with Scotsteel design software and transferred the designs directly to the roll forming machines using ScotRF software. This seamless digital-to-fabrication workflow ensured that every truss and every set of cold-formed steel wall panels matched the project’s demanding requirements.

Precision Manufacturing with Steel Framing Machines

The use of advanced steel framing machines proved essential in managing the complexity of the Opal project. Despite the oversized spans, the roll forming machines delivered exact specifications repeatedly, a testament to the reliability of cold-formed steel material.

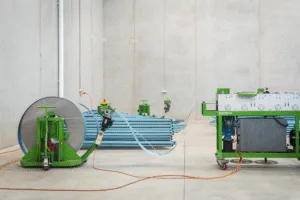

Flexibility in fabrication also became a key advantage of steel framing. The Scottsdale roll formers are portable, and their mobility allowed ISG Frames to reconfigure workshop space and manage large cold-formed steel truss assemblies within a limited floor area. This adaptability minimized bottlenecks and kept the production schedule on track.

Cold-Formed Steel Wall Panels and Cold-Formed Steel Trusses in Action

The Opal project required more than 40 tonnes of TRUECORE® steel. Through roll forming machines, ISG Frames fabricated structural components ranging from standard cold-formed steel wall panels to expansive cold-formed steel trusses. Each element contributed to a structure that met both engineering and architectural goals, supporting the creation of light-filled atriums and spacious communal areas.

Steel framed buildings like this demonstrate how cold-formed steel allows for high strength-to-weight ratios, reducing material bulk without sacrificing structural performance. The ability to create custom systems through roll forming technology gives builders freedom to design and deliver complex spaces while ensuring compliance with safety and code standards.

Steel Framing and Roll Forming Project Timeline

The project spanned multiple stages:

- Design Phase – 6 weeks: Detailing and engineering of the trusses and walls within the Scotsteel Software

- Manufacturing Phase – 6 weeks: Fabrication of all cold-formed steel walls and cold-formed steel trusses using Scottsdale roll forming machines: Scotpanel 7090 and Scottruss 6050.

- Installation Phase – 8 weeks: Close collaboration of ISG Frames with APM Group ensured smooth integration of cold-formed steel systems into the broader construction program.

This schedule illustrates how roll forming technology not only accelerates production but also aligns with complex construction timelines, helping projects remain on budget and on time.

Why Steel Framed Buildings Excel in Aged Care Construction

The Opal Aged Care project highlights the broader benefits of steel framed buildings:

- Durability: Cold-formed steel trusses and wall panels maintain their integrity over decades.

- Precision: Digital design-to-fabrication via steel framing machines eliminates errors.

- Efficiency: Roll forming technology enables faster builds compared to traditional construction methods.

- Flexibility: Repositionable roll forming machines adapt to project-specific challenges and ease the manufacturing process.

- Quality Assurance: Consistency across all cold-formed steel wall panels and trusses ensures long-term performance of the steel framed building.

- Safety: Cold-formed steel is noncombustible, making it an ideal choice for aged care facilities, as it enhances fire resistance and creates safer environments for residents.

For aged care, these benefits translate into safer, stronger, and more comfortable environments where residents can thrive.

Roll Forming Technology, the Foundation of Project Success

The Opal Aged Care facility in Clyde North stands as a clear example of how steel framing, roll forming, and steel framing machines redefine modern construction. Through the integration of roll forming technology, ISG Frames was able to fabricate complex cold-formed steel trusses and cold-formed steel wall panels that supported the vision for one of Australia’s most well-known aged care facilities.

Projects like this demonstrate that steel framed buildings are not only structurally superior but also adaptable to the specialized needs of sectors such as aged care. With the scalability of roll forming technology and the reliability of steel framing, the construction industry continues to push the boundaries of design, efficiency, and performance.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Key Reasons for Staggering Noggings in Cold-Formed Steel Wall Panels

- Blog – Best Practices and Advice for Bracing Using Steel Framing Machines

- Blog – Informative Research on Different Types of Cold-Formed Steel Trusses

- Blog – All You Need to Know: Cold-Formed Steel Trusses vs. Steel Joists

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Video – Scotpanel 7090G1 Steel Framing System

- Video – How to Make a Cold-Formed Steel Wall Panel Using Scotpanel 7090

- Video – Cold-Formed Steel Truss Rapid Fabrication Using Scottruss 6050G1

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.