Starting a steel framing business does not require a massive manufacturing facility or a long inventory of expensive equipment. In fact, many successful businesses in the industry have launched with just three essential components: one roll forming machine, one container, and one decoiler. This simple yet powerful setup is the most efficient entry point into the steel framing market. When paired with a mobile steel framing factory, it creates an operation that is compact, versatile, and capable of delivering cold-formed steel framing solutions directly to job sites. With the right roll forming machines, entrepreneurs can begin producing wall panels, trusses, and other framing components for residential, commercial, and modular construction projects in a matter of weeks.

Selecting the Right Roll Forming Machine

The roll forming machine is the heart of any steel framing business. It takes flat steel coil and transforms it into precisely engineered sections for walls, floors, roofs, and other structural elements. The quality, versatility, and capacity of the roll forming machine you choose will define your production capabilities and impact your long-term business growth. At Scottsdale Construction Systems, we offer five major families of roll forming machines that serve different needs in the steel framing industry. These roll forming machines are engineered for precision, durability, and ease of integration into permanent and mobile operations, ensuring that fabricators can produce high-quality cold-formed steel components efficiently and consistently.

The Scotpanel roll forming machines are one of the most versatile equipment available for starting a steel framing business. They produce C-sections that can be used in walls, roofs, ceilings, and support frames for low to mid-rise buildings. These C-sections are used in applications such as single and double-residential construction, commercial structures up to five stories, modular and off-site construction, partition walls in high-rise buildings, solar panel support frames, and prefabricated office fit-outs. Scotpanel roll forming machines offer multiple variations of C-sections, making them suitable for a wide range of cold-formed steel projects.

Explore the variations of C-sections manufactured by Scotpanel roll forming machines.

The Scottruss roll forming machines are high-capacity solutions designed for producing Hat-sections, which are used in roofs and floors across both residential and industrial projects. They are ideal for manufacturing roof panels, industrial roof trusses, floor joists, mezzanine floors, barn trusses, carport trusses, and more.

Explore the variations of Hat-sections manufactured by Scottruss roll forming machines.

The KFD Framemaker is a specialized roll forming machine built for producing non-structural cold-formed steel framing members. As a multi-profile machine, it can produce lipped and unlipped non-structural sections for use in internal partitions, suspended ceilings, bulkheads, and facades.

Explore the profile variations manufactured by KFD Framemaker roll forming machine.

The KFS Framemaker is designed for producing structural cold-formed steel framing members. It can manufacture lipped and unlipped structural sections used in load-bearing partitions, residential and commercial buildings up to ten stories, industrial facilities, and solar panel support frames.

Explore the profile variations manufactured by KFS Framemaker roll forming machines:

KSF Framemaker 1218, KFS Framemaker 1420, and KSF Framemaker 1622.

The KSE roll forming machines are built for producing non-structural cold-formed steel elements such as partitions, ceilings, bulkheads, and facades, making it ideal for fit-outs and light-duty framing applications.

Explore the profile variations manufactured by KSE roll forming machines.

Choosing the Best Roll Forming Machine for Your Business

When choosing a roll forming machine, it is important to assess your intended building applications, whether you plan to produce wall panels, roof trusses, floor joists, or prefabricated modular units. Profile requirements such as C-sections, U-sections, Hat-sections, custom shapes, and variations in web, flange, lip dimensions, and material thickness should be considered carefully and follow industry standards such as SFIA, AISI, and ICC-ES. Businesses must also decide whether a single-profile or multi-profile roll forming machine best suits their needs.

Integration with design processes is essential, so choosing a roll forming machine that supports Building Information Modeling (BIM) workflows, CNC file compatibility, and direct software control can make operations far more efficient. The mobility and footprint of the machines are also key factors, particularly for businesses operating a mobile steel framing factory. Beyond the purchase price, it is essential to factor in costs for setup, training, software, support, material sourcing, and labor. Lifecycle value, efficiency, and post-sale support from the manufacturer should be prioritized over the lowest upfront price.

Why Scotpanel is a Good Starting Point

For most entrepreneurs starting a steel framing business, the Scotpanel roll forming machine offers the best balance of versatility, portability, and affordability. Its compact size allows it to be installed in a standard shipping container alongside a decoiler, forming the basis of a mobile steel framing factory. This containerized setup can be transported directly to the jobsite, enabling on-site production and eliminating delays associated with transporting prefabricated materials.

The Scotpanel roll forming machine is not limited to wall panel production. It can also produce roof and floor trusses, expanding the range of projects a startup steel framing business can undertake. Its flexible power source options allow it to operate on single-phase or three-phase electricity and even on generators, making it highly adaptable to different environments, including remote or off-grid locations. Learn more about Scotpanel’s flexibility in power source options.

This combination of mobility, flexibility, and production capability is why many new steel framing businesses choose to start with a Scotpanel roll forming machine.

Mobile Steel Framing Factory Advantages

A mobile steel framing factory offers significant advantages over a traditional fixed-location facility. By housing the machine and decoiler inside a shipping container, production can be taken directly to the project site. This is especially valuable in remote areas where transportation of prefabricated materials would be costly or logistically challenging. In urban environments, the mobility of the containerized factory minimizes the need for large material storage areas and reduces traffic disruption on busy streets.

For disaster relief and emergency housing, a mobile steel framing factory provides a rapid solution. Cold-formed steel wall panels and framing components can be manufactured on-site, reducing reliance on external supply chains and enabling faster response times. This mobility also allows steel framing businesses to take on projects in multiple regions without the expense of maintaining separate permanent facilities.

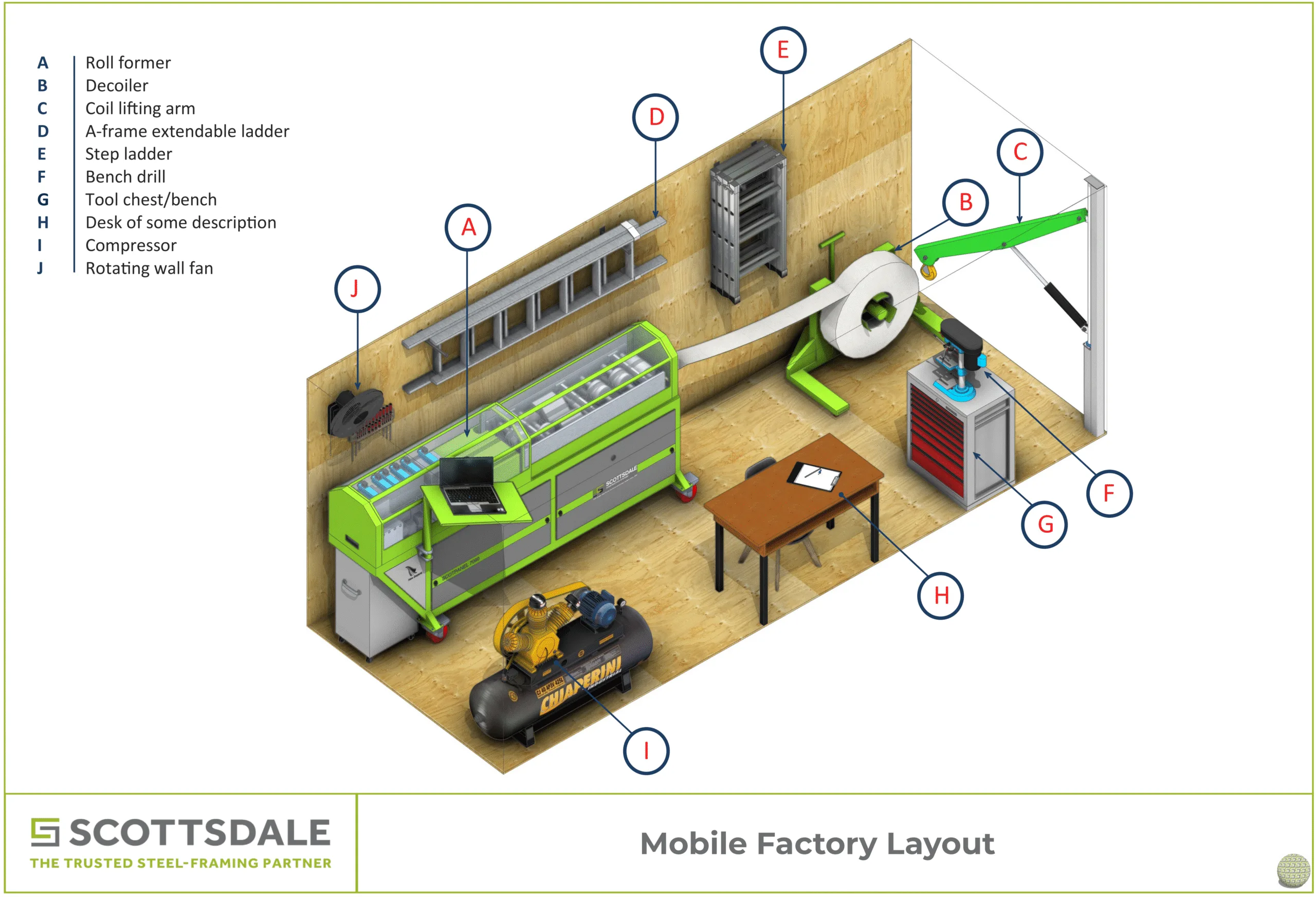

Inside a Mobile Steel Framing Factory

A mobile steel framing factory is designed for maximum efficiency in a compact space. The layout typically includes the roll forming machine, decoiler, and coil lifting arm, along with work platforms such as an A-frame extendable ladder and a stepladder. Supporting tools like a bench drill, tool chest or bench, and a compressor are positioned for easy access. Some setups include a desk for managing production files and a rotating wall fan for ventilation. The compact footprint of a containerized setup allows steel framing businesses to move from site to site while maintaining a fully equipped production environment.

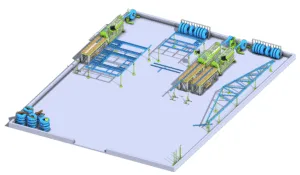

In situations where businesses wish to expand production capacity, the mobile factory concept can be scaled. Two containers can be positioned side-by-side with roof trusses spanning between them to create a permanent shaded workspace for assembling cold-formed steel wall panels, roof trusses, and floor trusses. This flexible approach allows the steel framing startup business to grow, easing the initial investment and capital needed to start a business.

Starting with a single mobile factory and one roll forming machine, the operation can grow into a permanent small facility using two containers, and eventually expand into a full-scale steel framing factory with additional roll forming machines integrated into the production lineup.

The Role of Decoilers in Roll Forming

The decoiler plays a vital role in ensuring smooth, continuous feeding of steel coil into the roll forming machine. A high-quality decoiler reduces downtime during coil changes and ensures consistent tension throughout the production process. Choosing the right decoiler for your setup can significantly improve efficiency and help maintain the precision of cold-formed steel profiles. Scottsdale offers a range of decoilers designed to work seamlessly with roll forming machines, ensuring that every stage of production is optimized.

Why Quality in Roll Forming Machines Matters

Roll forming assemblies are sophisticated systems that require precise engineering to perform reliably over time. Every aspect, from the forming cage to the integrated cutting and punching systems, must be designed to work together flawlessly. Inferior machines may fail to maintain tolerances, leading to wasted materials, rejected components, and costly delays. Selecting a reputable manufacturer with decades of experience in building and refining roll forming machines is essential for ensuring consistent quality and long-term durability.

Before purchasing a roll forming machine, visit a steel framing factory and observe the machine in operation, inspect the cold-formed steel framing it produces, and obtain insights into the machine’s performance and the quality of its output. Scottsdale has a network of steel framing factories operating our roll forming machines that allow factory visits to our new customers. Contact our sales team to get set up with a facility tour.

Before purchasing a roll forming machine, visit a steel framing factory and observe the machine in operation, inspect the cold-formed steel framing it produces, and obtain insights into the machine’s performance and the quality of its output. Scottsdale has a network of steel framing factories operating our roll forming machines that allow factory visits to our new customers. Contact our sales team to get set up with a facility tour.

Steel Framing Business: Start Small, Scale Fast

One of the greatest advantages of starting a steel framing business with a mobile Scotpanel setup is the ease of scaling operations as demand grows. Beginning with one roll forming machine, one container, and one decoiler allows you to establish your presence in the market with minimal overhead. As your business expands, additional machines and mobile units can be added, enabling you to take on larger and more complex projects.

With the right combination of equipment, training, and ongoing support, a small steel framing business can evolve into a major player in the cold-formed steel industry. From producing basic wall panels to delivering complete modular units, the possibilities are limitless. The steel framing industry continues to grow globally, and with a mobile steel framing factory, you are well-positioned to meet that demand efficiently and profitably.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Blog – Get Private Practical Training with Every Roll Forming Purchase

- Blog – Remarkable Results in Steel Framing with Roll Forming Technology

- Blog – Know How to Order Steel Coils for Roll Forming Operations

- Blog – Unlocking New Potentials with Cold-Formed Steel & Roll Forming

- Blog – Best Advice from Steel Framing Shops to Implement Today

- Video – The Best Containerized Factory Solution for Remarkable Steel Homes

- Video – Mobile Steel Frame Factory Using Scottsdale Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions, visit us at www.scottsdalesteelframes.com, call at +1 (888) 406-2080, or email at rollformers@scottsdalesteelframes.info.