In modern steel framing, constructability depends on the precision of roll forming machines, the intelligence of software, the sequencing of fabrication, and the detailing of steel framing connections. Sequencing and constructability are what define the next generation of fabrication and assembly for cold-formed steel framing members. As buildings become more complex, sequencing plays a critical role in ensuring that each member is fabricated in the right order, connections are accessible, and on-site installation is efficient. Today’s digital manufacturing technologies, like Scottsdale’s software suite, optimize constructability by sequencing every steel framing element, ensuring that each member is fabricated, labeled, and installed correctly.

The Role of Roll Forming Machines in Steel Framing Production

Advanced roll forming machines are at the heart of automated steel framing production. They convert flat coil into fully processed, cut-to-length cold-formed steel members complete with notches, holes, swages, and labels. When these roll forming machines are synchronized with fabrication software, they create a data-driven ecosystem where every roll forming steel framing member is produced in the exact sequence needed for efficient assembly.

This automated sequencing helps improve constructability by minimizing handling errors, avoiding clashes around openings, and ensuring all steel framing connections can be accessed easily during installation. The result is a streamlined production flow from the design phase through fabrication to on-site assembly, reducing labor time and ensuring every cold-formed steel member fits precisely as intended.

Understanding Steel Framing Connections for Constructability

Every building’s strength depends on its ability to transfer loads effectively from every building element to the foundation. In steel framing, a variety of essential cold-formed steel connections carry these loads. When steel framing connections are poorly detailed or inaccessible, construction delays and misalignments occur. For this reason, constructability begins with clear software-driven sequencing, ensuring cold-formed steel members are fabricated in a logical order for safe and easy assembly.

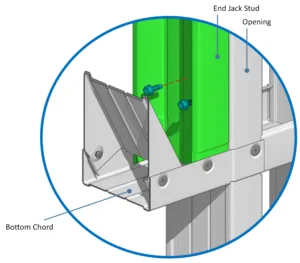

Connections around openings are particularly critical. Door and window areas involve more steel framing detailing, where members must be connected to carry both vertical and lateral loads. Proper sequencing of roll forming steel framing members ensures installers can access and fasten back-to-back studs, lintels, and sills correctly, maintaining the intended structural integrity.

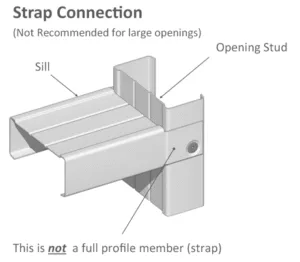

Strap Connections in Roll Forming Steel Framing

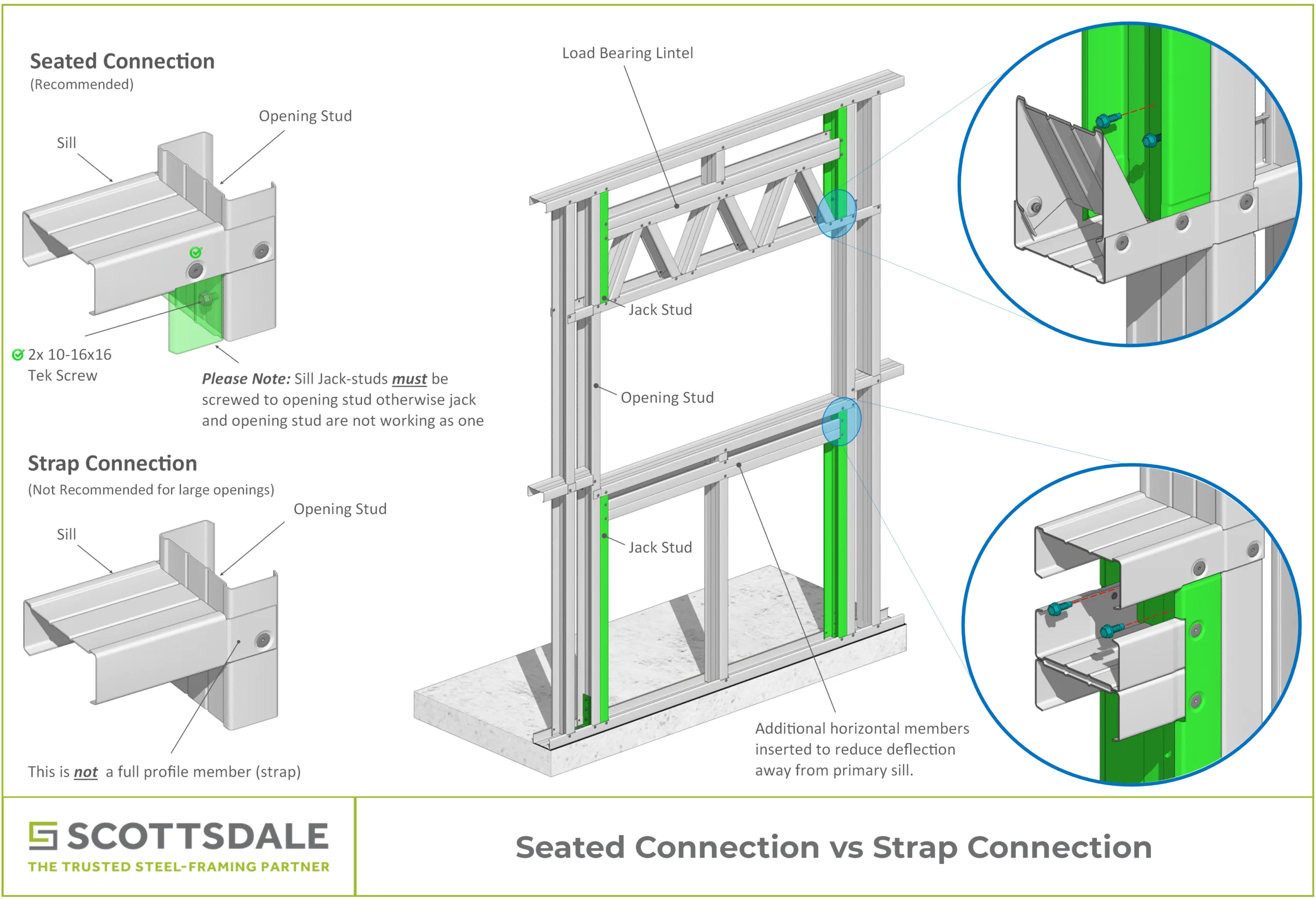

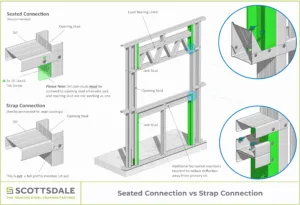

Strap connections are one of the most common types of steel framing connections used in cold-formed steel construction. In this method, two cold-formed steel members are joined where one profile is intentionally cut and is not a full member. The non-full profile member is connected via the strap to the other member, giving it the “strap connection” name.

The image below is an example of a strap connection between a sill and an opening stud. Fabrication software sequences these parts precisely, ensuring that roll forming machines cut, punch, and dimple each strap connection correctly. The result is faster on-site assembly and improved constructability, as installers know exactly which steel framing parts connect and where.

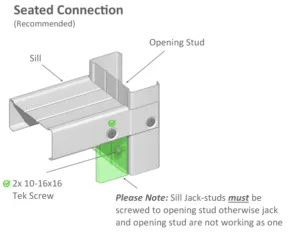

Full Seated Connections and Load Transfer

Full seated connections differ from strap connections in that they introduce an additional cold-formed steel member at the joint. This third member provides full bearing support, ensuring both profiles remain full-profile members where the load is transferred. For example, when a sill meets an opening stud, a jack-stud can be added in a back-to-back configuration, creating a continuous, full-depth support point. The joined steel framing members are then fastened together back-to-back (B2B) with Tek screws, typically No. 10 Tek screws, to make the two framing members act as one unit.

As detailed in Scottsdale’s article on cold-formed steel seated connections, these types of steel framing connections are vital for maintaining load paths and minimizing deformation. When roll forming machines fabricate these parts in the correct order, and when ScotRF sequences their installation, constructability is optimized, and site work becomes faster and safer.

Double Top Chord Lintel Connections

The lintel is one of the more structurally important steel framing components. A double top chord lintel must be fastened either back-to-back or via a flat sheet that spans the full depth, from the top of the upper member to the bottom of the lower member. Properly fabricated and sequenced cold-formed steel members ensure that these connections behave as a single structural unit, effectively transferring loads from around the openings to supporting studs and down to the foundation.

With intelligent sequencing in ScotRF software, roll forming steel framing members are not only fabricated to precise lengths and hole patterns but also labeled for quick identification. This ensures installers can easily locate and connect each component, reinforcing the importance of digital fabrication workflows in steel framing constructability.

Software Sequencing: The Key to Constructability

Constructability is not just about the design of steel framing and cold-formed steel systems; it’s about accessibility and efficiency during assembly. Sequencing determines how cold-formed steel members are fabricated, labeled, and delivered. By ensuring the right roll forming steel framing members are produced in the correct order, ScotRF software simplifies complex systems, such as around openings and lintels, where access for fastening is often limited.

ScotRF’s sequencing algorithms consider every steel framing detail: which members should be fabricated first, where access holes must be maintained, and how back-to-back members can be connected without interference. When integrated with roll forming machines, this results in fewer on-site adjustments, reduced labor hours, and enhanced constructability across projects.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Smarter Roll Forming for Better Steel Framing Connections

The future of steel framing lies in the synergy between design software and roll forming machines. By sequencing roll forming steel framing members intelligently, ScotRF improves constructability, ensures accurate steel framing connections, and enhances the quality of every structure built with cold-formed steel members. From full seated assemblies to lintel detailing and more complex steel framing systems, precise fabrication and sequencing drive faster, safer, sustainable, and more efficient construction.

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – The best Data-Driven Roll Forming Technology for Steel Framing Production

- Blog – ISG Frames Delivers an Epic Project with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Blog – Best Advice from Steel Framing Shops to Implement Today

- Video – Building Better Steel-Framed Tiny Homes with Roll Forming Technology

- Video – Fast and Easy Riveting in Cold-Formed Steel Framing

- Video – Steel Framing Panelizing Progress for Offsite Construction

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.