In the world of cold-formed steel, precision manufacturing depends on advanced roll forming technology and the intelligent operation of every roll forming machine. Among the many forming processes, cutting, notching, punching, dimpling, and flattening, the swaging of cold-formed steel members stands out as one of the most essential. The process of swaging, including both end-swage and interior-swage, allows structural elements to connect more effectively, enhancing the load-transfer performance of steel framing systems. Modern automation has transformed how the swaging of steel framing members is performed, ensuring every cold-formed steel profile is produced with consistent precision across residential, commercial, and industrial projects.

Understanding the Swaging Process in Cold-Formed Steel Manufacturing

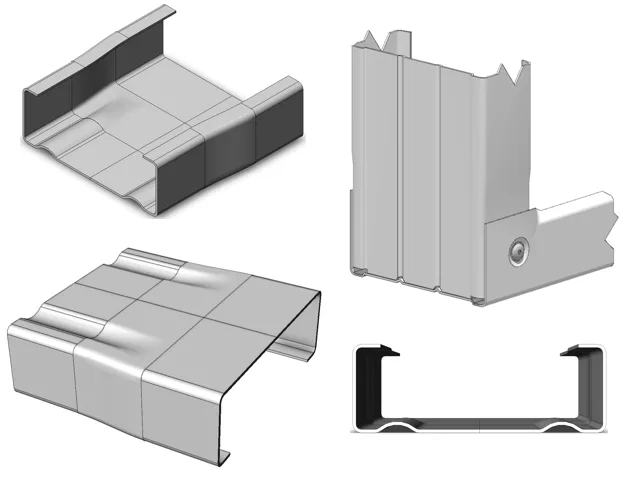

Swaging is a controlled deformation process that reduces or offsets the profile of a cold-formed steel section at specific points. This can occur at the end of a member (end-swage) or along the web (interior-swage). Using compressive forces, the swaging of a steel framing member slightly decreases the width of the section to ensure a tight, accurate fit within another profile. The result is a smoother assembly that improves both connection capacity and load-transfer efficiency.

In structural applications, such as trusses or telescoping assemblies, the swaging of cold-formed steel members is used to achieve end-bearing connections. This means that rather than relying solely on rivets or screws, the member can bear directly against another element, maximizing its load-carrying capacity. This improvement in connection performance is one of the most important advantages of integrating swaging capabilities directly into the roll forming process.

Automated Roll Forming Machines and Integrated Swaging Technology

Today’s roll forming lines, such as those produced by Scottsdale and Knudson by Scottsdale, incorporate a range of automated tool heads, including cutting, notching, punching, and swaging. Each roll forming machine uses software to communicate precise tooling commands for the swaging of cold-formed steel members, whether end-swage or interior swage.

Full software-controlled swaging operations are standard on all Scotpanel and Scottruss roll forming systems, meaning the swaging of steel framing members is built into every machine’s process. This level of integration ensures consistent accuracy, faster production, and minimal manual adjustment. For KFS Framemaker and KFD Framemaker roll forming machines, swaging is available as an optional tooling package for custom manufacturing requirements.

Functional Variations: End-Swage vs. Interior-Swage

The two primary configurations, end-swage and interior-swage, serve distinct engineering purposes. The end-swage operation is the most common form of swaging of steel framing members, used at the profile ends to create end-bearing connections. This configuration forces the member to transfer loads directly through bearing rather than through fasteners alone, resulting in a better connection compared to a non-swaged section.

On the other hand, interior-swage operations are applied mid-length along the web of a cold-formed steel section. An interior-swage allows one section to pass through or fit snugly within another without distortion, preserving panel alignment and the quality of finishes during sheathing.

Mini-Swage: Precision Fit for Enhanced Steel Framing Assembly

In addition to swaging, our roll forming systems can perform a “mini-swage”, an important adaptation within our modern roll forming machines. The mini-swage slightly rounds or compresses the edge of a cold-formed steel stud where it meets a supporting track, ensuring that the allowable gap between the stud and track, typically limited to 1/8 in., is eliminated. This micro-adjustment enhances stability in steel framing assemblies and ensures perfect seating within the track, a subtle but significant improvement in overall connection quality.

Manufacturers who rely solely on retail studs often face difficulties because these parts are not produced with project-specific swaging of cold-formed steel member operations. Automated roll forming systems solve this problem by executing every swaging operation precisely where it is needed, according to the digital design data supplied by engineering software.

Software Automation and Communication with the Roll Forming Machine

The efficiency of swaging of steel framing members lies in the seamless communication between the design software and the roll forming machine. Bespoke control software such as ScotRF enables automation of cutting, punching, notching, and swaging operations at predefined locations. This eliminates the need for manual input, reduces human error, and guarantees that every cold-formed steel member is fabricated exactly as modeled, no matter the complexity of the project.

These automated commands ensure that every end-swage and interior-swage occurs at the right position with the correct depth and profile adjustment, maintaining precision across entire wall, truss, and floor assemblies.

Structural Benefits of Swaging in Cold-Formed Steel Framing

From an engineering perspective, the swaging of cold-formed steel members increases the efficiency of load transfer in framing joints, particularly in high-load or multi-story structures. The ability to create a bearing connection at each end-swage minimizes reliance on fastener strength and instead utilizes the inherent bearing strength of the profile. Similarly, interior-swage operations enable better nesting of members in intersecting configurations, improving fit and reducing distortion.

Whether producing wall panels, trusses, or joists, swaging provides the geometric refinement necessary for advanced cold-formed steel systems to meet demanding design standards. When integrated into an automated roll forming line, the result is a more reliable, higher-performing framing product.

The Role of Swaging in Advanced Roll Forming Systems

As cold-formed steel construction continues to evolve, processes like swaging remain fundamental to precision manufacturing. Through the advanced automation of every roll forming machine, operations such as end-swage, interior-swage, and mini-swage are carried out seamlessly, transforming complex structural details into efficient, repeatable fabrication outcomes. The combination of intelligent roll forming controls and the automated swaging of steel framing members ensures that builders, engineers, and manufacturers achieve higher structural integrity, faster assembly, and greater consistency in every project built with cold-formed steel.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Blog – The Best Data-Driven Roll Forming Technology for Steel Framing Production

- Blog – Best Practices and Advice for Bracing Using Steel Framing Machines

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – A Better Inexpensive Ergonomic Steel Framing Fabrication Process

- Blog – How to Launch a Successful Steel Framing Business

- Video – Successful Remote Location Mobile Factory Fabrication

- Video – Steel Truss Rapid Fabrication Using Scottruss 6050G1

- Video – Steel Framing Fabrication Process with Scotpanel and Scottruss Roll Forming Systems

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.