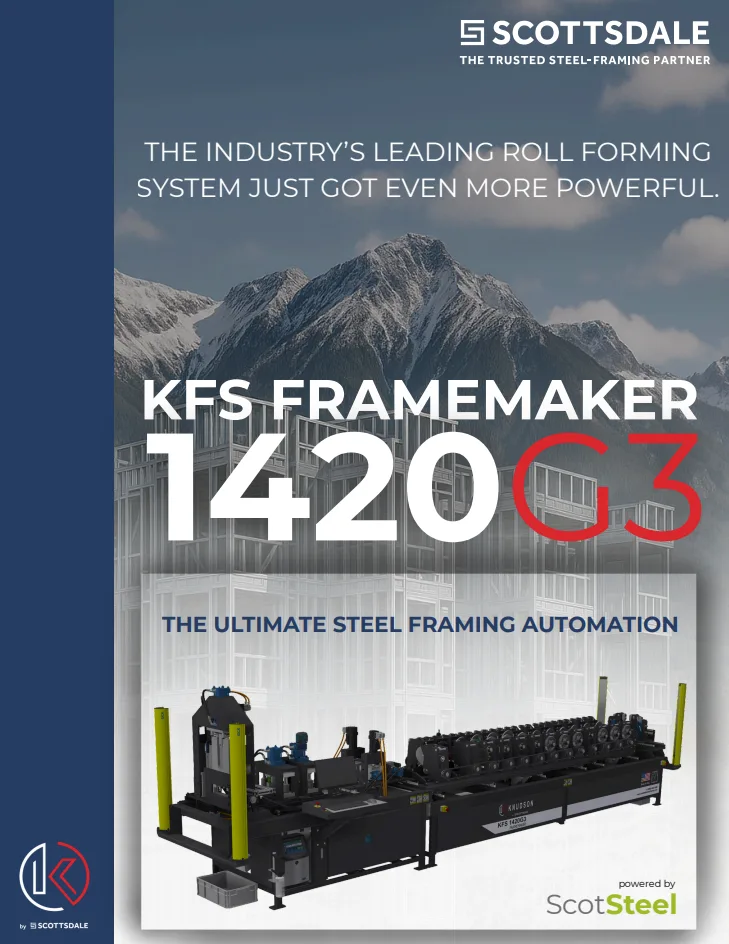

Scottsdale Construction Systems is proud to introduce the KFS Framemaker 1420G3, the newest addition to our family of roll forming machines, a true milestone in steel framing technology and steel framing automation. Designed for today’s builders, engineers, and fabricators, this leading roll forming system redefines what’s possible in cold-formed steel framing construction.

The KFS Framemaker 1420G3 combines the precision of advanced roll forming machines, the intelligence of digital steel framing automation, and the performance of a leading roll forming system engineered for reliability and speed. Built for global standards in cold-formed steel, it delivers efficiency, consistency, and strength across residential, commercial, and industrial applications.

What Are KFS Framemaker Roll Forming Machines?

The KFS Framemaker series of roll forming machines is globally known for producing structural members in cold-formed steel construction. These machines are engineered to fabricate both lipped and unlipped channel sections used in high-strength steel framing, allowing builders to produce load-bearing and non-load-bearing components for cold-formed steel walls, partitions, and more.

With the G3 generation, this leading roll forming system now offers unparalleled steel framing automation, giving fabricators faster setups, higher throughput, and tighter tolerances. Designed to fabricate cold-formed steel members that meet AISI S100, CSA 136, EN 1993-1-3, and AS/NZ 4600 standards, the KFS Framemaker ensures every profile meets stringent global requirements in steel framing systems.

The KFS Framemaker 1420G3 Roll Forming Machines: A New Benchmark

The new KFS Framemaker 1420G3 roll forming machine builds upon the success of previous multi-profile machines with advanced automation and faster operation. It fabricates Cee-sections and U-sections ranging from 3.5 in. to 12 in. deep and 1.63 in. to 3.00 in. wide. This next-generation roll forming machine features:

- 6× faster changeover compared to the industry average—2.5× faster than the G2—thanks to automated servo-controlled roller adjustment.

- A 10% higher operating speed than the G2, ensuring greater production capacity and improved steel framing automation.

- A fully integrated ecoDecoiler that uses gravity-feed technology, eliminating the need for power and reducing energy use.

These enhancements make the KFS Framemaker 1420G3 the most efficient and sustainable roll forming machine for manufacturers seeking to improve productivity and lower operating costs.

Download the KFS Framemaker 1420G3 Brochure.

More information on the KFS Framemaker 1420 roll forming machines.

Integrated Steel Framing Automation for the Modern Fabricator

At its core, the KFS Framemaker 1420G3 embodies the evolution of steel framing automation. Equipped with an advanced 16-axis BOSCH Rexroth control system, it ensures high-level accuracy and seamless operation throughout production.

The G3 system’s intelligence goes beyond mechanics; it connects to digital design environments like Revit and MWF, making it the most integrated leading roll forming system on the market. Through real-time data tracking and software-driven sequencing, every cold-formed steel member is labeled, cut, and fabricated precisely in order, ready for fast assembly either onsite or off-site.

This connectivity transforms traditional roll forming machines into automated manufacturing ecosystems that align digital design and real-world fabrication.

Smarter Design, Stronger Performance in Steel Framing Technology

The KFS Framemaker 1420G3 inherits all the features our customers loved in the G1/G2, including:

- Adjustable punch toolkit

- Track slotting toolkit

- Inkjet labeling

- Computer-driven functionalities

- And more

What sets the G3 apart is its integration within a leading roll forming system that emphasizes both efficiency and sustainability. With steel framing automation and improved control software, changeovers are quicker, material handling is smoother, and power consumption is lower, delivering the future of steel framing technology today.

Software Integration and Customization Options

The KFS Framemaker 1420G3 connects seamlessly with Scottsdale’s advanced software suite and a variety of third-party design platforms. Through steel framing automation, users can integrate Revit-based models directly into the production workflow, reducing rework and ensuring design intent is preserved.

Every roll forming machine can be customized with more than 40 additional tooling options, from cutting and notching to swaging, flattening, and coping, offering flexibility for specialized cold-formed steel applications such as box columns, telescoping frames, solar support structures, and more.

This adaptability makes the KFS Framemaker 1420G3 not just a leading roll forming system, but a configurable production solution built for any scale of projects worldwide.

Manufacturing Reliability Meets Data-Driven Efficiency

Beyond mechanical advancements, the new KFS Framemaker 1420G3 was engineered for long-term durability and reduced maintenance. Built with premium components and advanced diagnostics, it supports operation for high-volume fabricators seeking dependable steel framing technology.

With data connectivity and inventory tracking, customers can monitor coil usage, profile output, and maintenance schedules in real time. This intelligent steel framing automation approach provides measurable savings, up to $200,000 or more in annual production impact, through faster throughput, fewer manual adjustments, and lower power usage.

Experience the Leading Roll Forming System

As the world advances toward digital construction, the KFS Framemaker 1420G3 stands as the benchmark in roll forming machines, merging sustainability, performance, and intelligent control in one complete ecosystem.

This is more than just a new roll forming machine; it’s the evolution of steel framing technology and a showcase of Scottsdale’s commitment to innovation in cold-formed steel manufacturing. Contact our sales team for more information on the KFS Framemaker 1420G3 roll forming machine today!

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Blog – Grow Your Competitive Edge with In-House CFS Fabrication

- Blog – Scottsdale Ecosystem: World Famous Roll Forming Equipment and Powerful Software

- Blog – The Best Data-Driven Roll Forming Technology for Steel Framing Production

- Video – Knudson by Scottsdale KFS Framemaker 1420 G1 Roll Former

- Video – Knudson by Scottsdale KFS Framemaker 1420 G1 in Action

- Video – Knudson by Scottsdale Roll Former KFS Framemaker 1420 G1 Used to Build Amazing Church

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.