The construction industry is standing at a generational crossroads. According to recent data from the National Association of Home Builders (NAHB), the median age of the construction labor force is 42, but beneath that number lies a powerful shift: younger generations are stepping in, bringing with them a demand for smarter tools, faster results, and safer working conditions. For this new construction labor force, roll forming technology, and cold-formed steel framing represent not just new construction methods, but a new way of building; one where technology does the heavy lifting, and human effort focuses on precision, creativity, and progress. As the industry modernizes, steel framing and roll forming systems are leading the charge toward a faster, safer, and more efficient future.

Link to Median Age of Construction Labor Force Economic Research by Eye On Housing – NAHB.

The New Generation of Builders Is Changing the Game

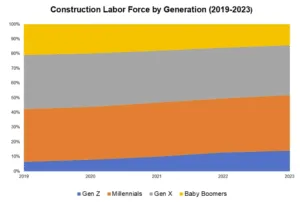

Millennials and Gen Z are entering the construction labor force with a completely different mindset. They value innovation, digital tools, and efficiency over brute force and repetitive manual labor. Between 2019 and 2023, the share of Gen Z workers in construction more than doubled, rising from 6.4 % to 14.1 %, while Baby Boomers dropped from 20.6 % to 14.2 %. This isn’t just a demographic shift, it’s a technological one. View the construction labor force by generation (2019-2023) data below.

Source: Eye on Housing National Association of Home Builders Economic Research Blog

These new builders aren’t content with outdated processes or equipment that demand physical wear and tear. They want to work with intelligent systems that streamline fabrication, improve safety, and deliver instant results. That’s exactly where roll forming technology comes in. These roll forming innovations automate what used to take teams of workers days to complete, creating precision-engineered cold-formed steel framing components that fit together like a puzzle. For a construction labor force that grew up on technology, new construction methods that rely on software-driven roll forming and modern steel framing aren’t intimidating; they’re inspiring.

Letting Roll Forming Technology Do the Heavy Lifting

The appeal of roll forming lies in its simplicity and power. Instead of cutting, measuring, and drilling materials by hand, advanced roll forming technology automates every step, from coil feeding to punching, labeling, and cutting, all controlled by cutting-edge design software. This shift not only boosts speed and accuracy but also drastically reduces physical strain on workers.

Younger members of the construction labor force recognize the advantage. Why spend hours lifting, hammering, and re-measuring when new construction methods powered by roll forming technology can fabricate cold-formed steel framing that’s ready to assemble straight off the line? These systems allow teams to build faster, build better, and preserve the health and longevity of their workforce. The result is a jobsite where technology carries the load and people focus on assembly, coordination, and quality control.

Cold-Formed Steel Framing: The Backbone of Modern Construction

Cold-formed steel framing is the perfect match for a generation that values precision, sustainability, and speed. Unlike traditional materials, steel framing doesn’t warp, twist, or rot. It’s recyclable, non-combustible, and engineered to last, traits that resonate deeply with workers who care about long-term impact and smart design.

When produced through roll forming technology, cold-formed steel framing becomes even more efficient. Components are fabricated directly from digital models, punched for service holes, labeled for assembly, and cut to exact lengths in seconds. For the modern construction labor force, these automated workflows align perfectly with the desire to let machines handle the repetitive work while humans manage outcomes. Roll forming and steel framing don’t replace people, but they empower them with digital tools that multiply productivity while minimizing fatigue and error.

New Construction Methods for a New Kind of Workforce

The rise of roll forming technology and cold-formed steel framing isn’t just about materials; it’s about the mindset. The new construction labor force wants to solve problems creatively, use data intelligently, and build efficiently. They see technology as a collaborator, not a competitor.

New construction methods built around roll forming and steel framing make this collaboration possible. Digital designs translate seamlessly into production, panels are fabricated with minimal waste (often less than 1%), and assembly becomes a matter of coordination rather than strength. For workers entering the field today, this approach redefines what construction looks like: safer jobsites, shorter learning curves, and a sense of pride in working with high-tech, precision-based systems that reflect the future of the trade.

Faster Builds for a Greater Impact

The easier it is to build, the faster we can close the housing gap. When roll forming technology simplifies cold-formed steel framing production, each structure requires fewer labor hours per home, freeing the construction labor force to complete more projects in less time. These new construction methods make large-scale community building not only possible but practical. Entire neighborhoods can be framed in weeks instead of months, accelerating the delivery of affordable, high-quality homes. As a result, more families become homeowners, communities grow stronger, and the construction industry fulfills its greatest purpose: building better lives through smarter technology and efficient steel framing systems.

The Future Is Built Smarter with Roll Forming

As the construction labor force continues to evolve, roll forming technology, cold-formed steel framing, and new construction methods are setting the standard for what comes next. The new generation doesn’t want to swing hammers forever; they want to program, operate, and optimize. They want to build faster and build better while preserving their bodies and their enthusiasm for the trade.

By embracing roll forming and cold-formed steel framing, the industry isn’t just adapting to workforce change; it’s creating a better version of itself. This is the era of smarter construction, where automation, precision, and purpose come together to build the future of steel framing and the future of those who build it.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – See How Roll Forming Technology is Redefining Steel Framing

- Blog – 5 Great Reasons to Use Cold-Formed Steel in Modular Construction

- Blog – How to Make Walls and Ceilings with Roll Forming Technology

- Blog – Extra Insurance Savings and Premiums Delivered with Steel Framing

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Reasons to Invest in a Multi-Profile Roll Forming Machine

- Blog – How to Launch a Successful Steel Framing Business

- Blog – Ultimate Guide to Steel Framing Manufacturing Shop and Floorplan

- Video – The Best Containerized Factory Solution for Remarkable Steel Homes

- Video – Why Tag Frames Trusts Scottsdale in Roll Forming Technology

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.