A modern two-story steel-framed structure achieved speed, accuracy, and fully integrated design-to-production workflows by combining roll forming, advanced steel framing, and precision manufacturing of CFS wall panels, CFS floor joists, and high-performance CFS truss systems. In this 321-square-meter residential example, every major framing component was designed to be produced through automated roll forming processes, ensuring consistent quality and rapid delivery. This seamless ecosystem of steel framing and roll forming technology enables tighter coordination, faster construction timelines, and a more efficient, fully engineered steel-framed structure.

Project Overview

A Modern Two-Story Steel-Framed Structure in Queensland

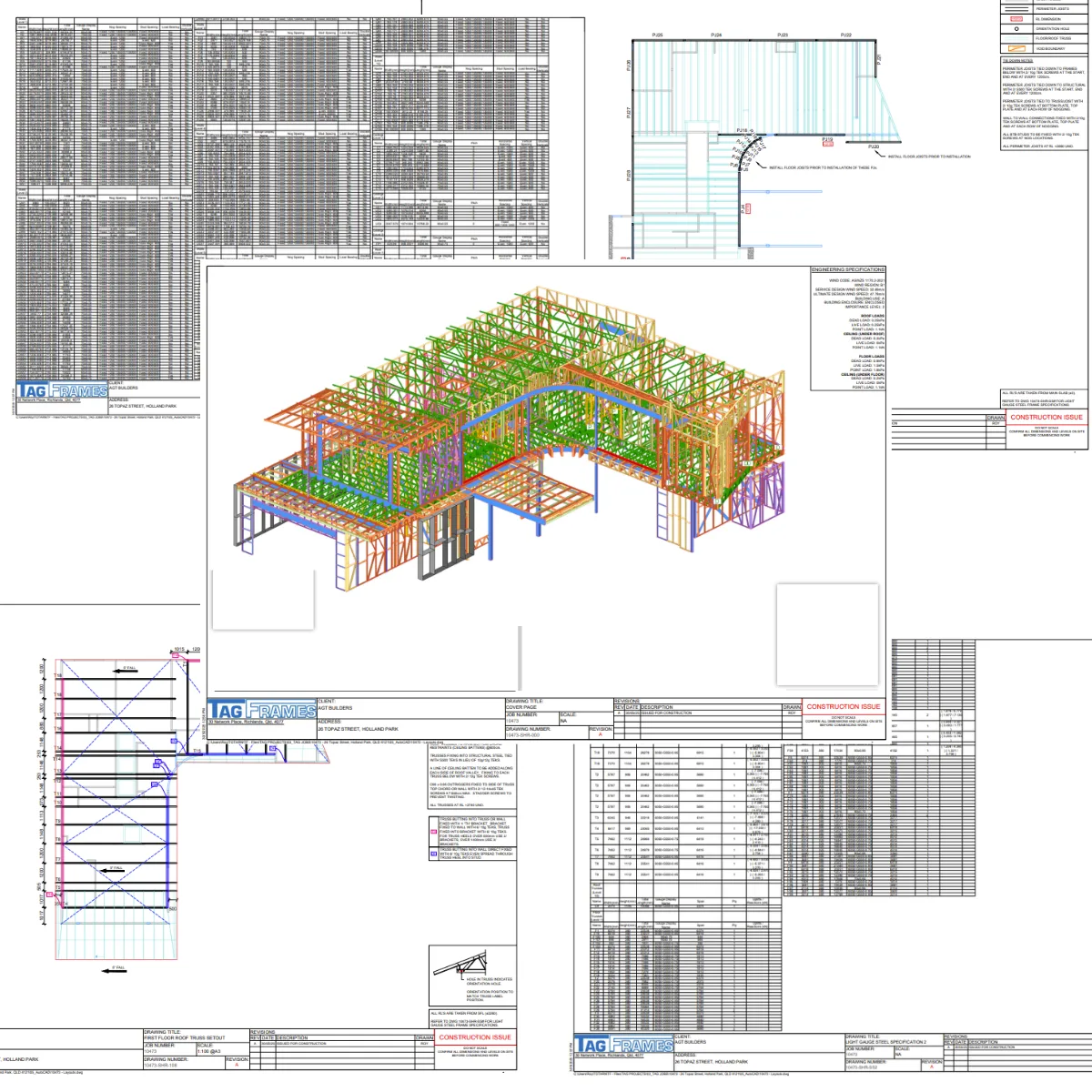

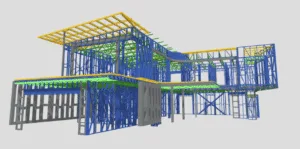

This residential project in Holland Park, Queensland, showcases what can be achieved when a builder integrates roll forming and a fully engineered steel-framed structure from the start. The home spans 321 square meters, featuring modern architecture, a double garage, multiple skylights, a curved structural beam, a covered porch, and an upper-level balcony. The entire building is supported by steel framing, with critical load-bearing members generated through high-strength CFS floor joists, a CFS truss system, and load-bearing and non-load-bearing CFS wall panels.

TAG Frames, a steel framing manufacturer operating a Scottruss 6050 and Scotpanel 7090 roll forming machines, was able to prepare a complete quote package for their customer in a fraction of the time typically required with traditional materials. Their automated process ensured the steel-framed structure was fully coordinated before fabrication, from engineering to builder-friendly documentation.

Manufacturing Precision

CFS Wall Panels, CFS Floor Joists, and CFS Truss System Fabrication

TAG Frames’ quote package included:

- 90mm prefabricated CFS wall panels

- 400mm deep CFS floor joists

- CFS roof truss system spaced at a maximum of 1200mm on center

- 22mm ceiling battens at a maximum of 600mm on center

- Structural steel integration

- Bracing and tiedown as recommended by their in-house engineer using ScotSteel software package

- All fixings, bracketry, and bracing

- Prefabricated and site delivered via crane truck

Each component, whether from the CFS wall panels, CFS floor joists, or the CFS truss system, is to be fabricated using Scottsdale Construction Systems’ automated roll forming machines. The Scottruss 6050 produces both the CFS floor joists and the CFS truss system, while the Scotpanel 7090 produces the vertical load-bearing and non-load-bearing CFS wall panels.

Scottsdale Construction Systems’ roll forming automates web openings, whether plumbing holes or service holes, tie-down punches, slotting, labelling, and even optimizes fabrication based on assembly efficiency. Every piece arrives ready for rapid assembly. This ecosystem ensures that the steel framing package is not only complete but also optimized for speed and accuracy on-site.

Documentation and Visualization

Enhancing the Steel Fabrication and Project Workflow

TAG Frames provided a comprehensive project-specific package that extended beyond just pricing. Their submittal included full layouts, steel drawings, panelized breakdowns, and CFS connection details, each directly from the architectural drawings. A 3D model of the home’s steel framing system was also shared, enabling the customer to visualize how the CFS wall panels, CFS floor joists, and CFS truss system integrate to form a cohesive solution.

To aid decision-making, TAG Frames also provided examples of a similar completed home. This allowed their customer to see how efficiently a previous steel-framed structure had been fabricated and erected, setting great expectations for timelines and quality.

Speed of Project Delivery

Roll Forming and Steel Framing for Rapid Construction

One of the strongest advantages of roll forming with a complete steel framing ecosystem is the speed of manufacturing. Homes of this size typically see all CFS wall panels, CFS floor joists, and CFS truss system components fully fabricated within a few days. On-site assembly of the resulting steel-framed structure can also be completed within days, thanks to the lightweight nature of steel framing and the advantages of cold-formed steel material.

This project is just another demonstration that roll forming reduces labor hours, minimizes waste, and simplifies the transition from architectural drawings to construction. By automating the production of CFS wall panels, CFS floor joists, and the CFS truss system, the builder avoids many of the delays and inconsistencies common in traditional framing.

Roll Forming Ecosystems Help Manufacturers Quote, Win, and Deliver Jobs

Automated roll forming paired with intelligent steel framing workflows enables manufacturers like TAG Frames to quote projects more accurately, fabricate with less waste, and erect a steel-framed structure more quickly. With coordinated production of CFS wall panels, CFS floor joists, and CFS truss systems, fabricators gain a clear competitive advantage. This project illustrates how modern residential construction continues to evolve and how a complete roll forming ecosystem empowers manufacturers to design, price, fabricate, and assemble projects with far greater efficiency and confidence.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Why TAG Frames Trusts Scottsdale in Roll Forming Technology

- Blog – All You Need to Know About Safe Handling of CFS Frames

- Blog – How to Make Walls and Ceilings with Roll Forming Technology

- Blog – Fire and Acoustic Ratings in Cold-Formed Steel Assemblies Simplified

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – A Better Path Towards Sustainability with Roll Forming Technology

- Blog – Unlimited Possibilities with Scottruss High-Tech Roll Forming Machine

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.