Proper handling of cold-formed steel (CFS), CFS trusses, and CFS wall panels is crucial to ensure both safety and efficiency during transport, storage, and installation. These CFS frames are lightweight yet strong, allowing for easy movement onsite and offsite, but only when managed correctly. Understanding CFS handling tips can minimize the risk of damage, streamline logistics, and maintain structural precision throughout the building process.

Stacking CFS Wall Panels and CFS Trusses

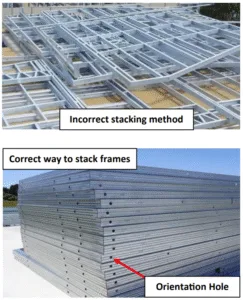

Stacking is one of the most critical aspects of CFS handling tips, as poor stacking can lead to distortion or safety hazards. When stacking CFS wall panels or CFS trusses, always ensure that each component is clearly labeled and visible for quick identification. Stack the frames so that the orientation holes in the bottom plate are all positioned on the same side. This alignment simplifies identification and speeds up installation when the CFS frames are raised into position.

Begin stacking by laying the first cold-formed steel panel completely flat and ensuring it isn’t twisted. As more CFS wall panels or CFS trusses are added, the pressure builds on the lower units, so it’s vital to stack them on level blocks spaced 1000 to 1500 mm apart. These blocks should always align with the perimeter joints of the CFS frames to evenly distribute weight and avoid deformation.

Ensure that the stacking surface is solid, level, and located away from walkways or emergency exits. Stack cold-formed steel panels horizontally unless vertical stacking has been specifically engineered. Maintain at least one meter of clearance around each stack to allow for inspection and safe access, keeping 450 mm from any walls and one meter from ceilings or sprinkler systems.

Organize CFS wall panels in order of installation: the panels needed for upper floors should be stacked first, with ground-floor frames placed last for faster loading. For maximum stability, start stacking with large panels, fill gaps with smaller ones, and finish with layers of large panels on top.

Transportation and Handling of Cold-Formed Steel Members

When it comes to CFS handling tips for transport, organization and planning are key. Avoid sending all CFS wall panels and CFS trusses to the job site at once unless there’s sufficient storage space. Staggered deliveries reduce onsite congestion and improve workflow efficiency.

Handle all cold-formed steel components with care to avoid bending, scratching, or denting. The galvanized coating on CFS frames serves as a critical corrosion barrier, any scratches that expose the steel surface can compromise durability and reduce the lifespan of the cold-formed steel member. During transport, ensure that CFS trusses and CFS wall panels are fully supported in either horizontal or vertical planes to prevent buckling or crushing.

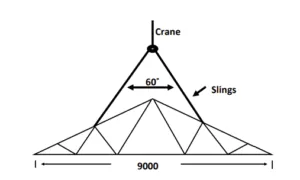

When lifting with a crane, use appropriate rigging methods to prevent damage at the lifting points. Sling CFS trusses from the chord and web points, and CFS wall panels from the top plate and stud connections. Position slings equidistant from the center line, about one-third to one-half the total span apart. Keep the sling angle below 60 degrees to distribute the load evenly and prevent bending.

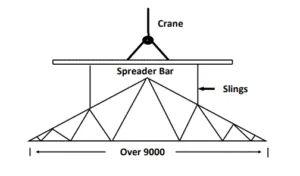

For CFS trusses with longer spans, typically those exceeding 9000 mm, use a spreader bar or strongback to provide additional support. These lifting aids help distribute the load evenly across the cold-formed steel components, reducing stress on connection points and maintaining the geometry of the CFS frames.

Improving Workflow with Proper Handling of CFS Frames

Efficient handling of CFS wall panels and CFS trusses is not just about safety; it also enhances workflow and project sequencing. Following consistent CFS handling tips allows fabrication teams and installers to move seamlessly from production to assembly, avoiding costly delays caused by damaged materials or misaligned stacks.

Whether working in an offsite manufacturing facility or on a construction site, disciplined handling of cold-formed steel systems ensures that each frame arrives ready for precise installation. In turn, this reduces waste, improves site safety, and supports the overall productivity of every project built with CFS wall panels and CFS trusses.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – Overcome Complex CFS Truss Design with New Steel Framing Technology

- Blog – How to Make Walls and Ceilings with Roll Forming Technology

- Blog – ISG Frames Delivers an Epic Project with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Blog – Innovative Disruptors in Modular Construction with Roll Forming Technology

- Video – Why Tag Frames Trusts Scottsdale in Roll Forming Technology

- Video – STALART: How to Create Construction Innovation with Awesome Roll Formers

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.